Single-color SMD LED positioning die assembly pasting device for computer communication and method thereof

A computer and positioning mold technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve problems such as the inability to accurately position and transport single-color SMD LEDs, and the inability to effectively improve the placement efficiency of placement machines, and achieve improved The effect of mounting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

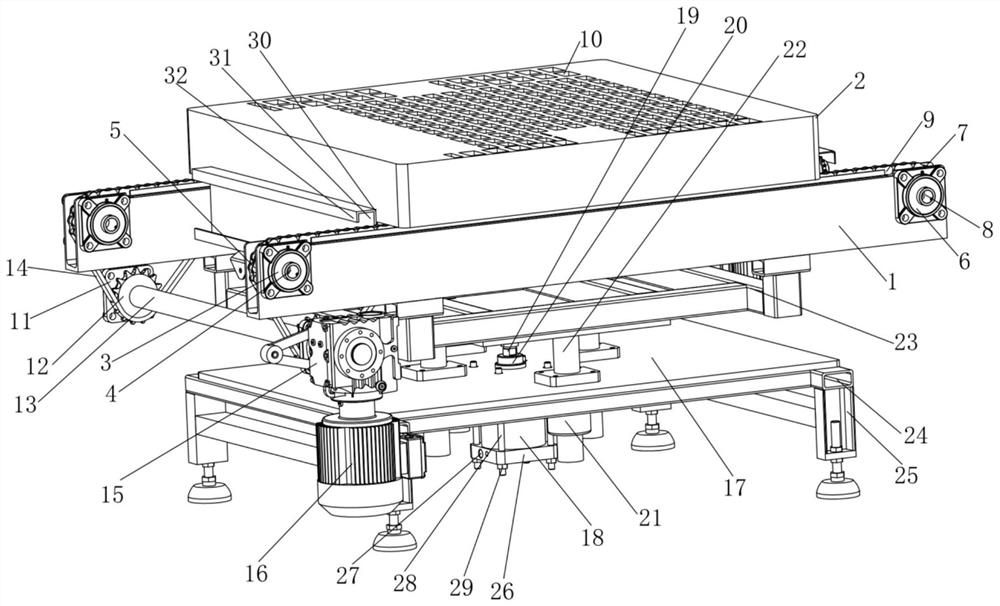

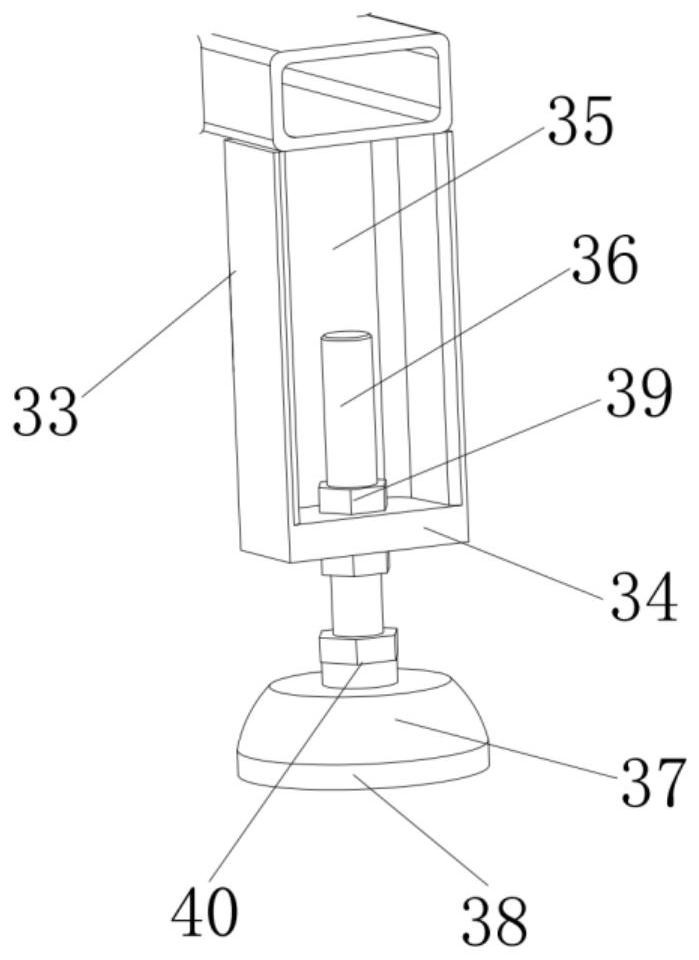

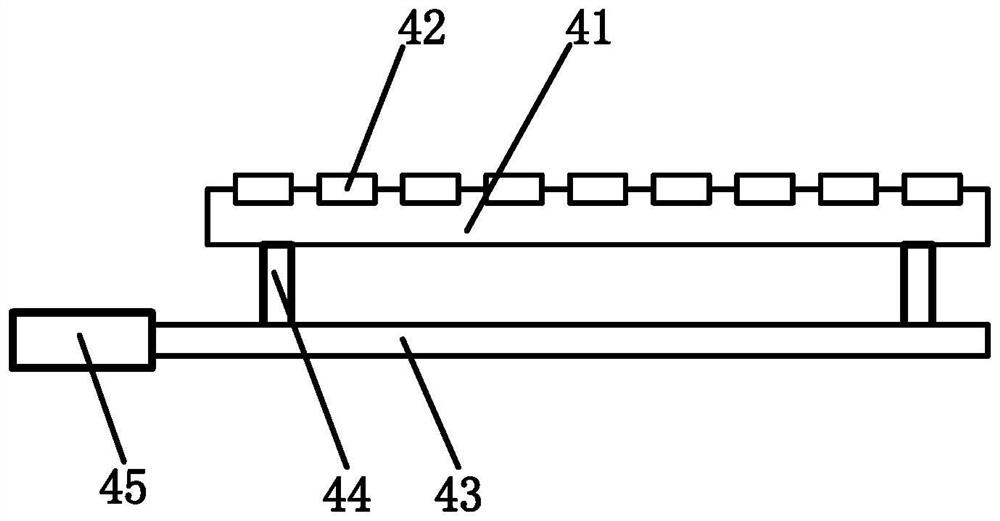

[0077] This embodiment provides a preferred implementation, such as Figure 1 to Figure 6 As shown, a single-color chip LED positioning module assembly and mounting device for computer communication includes two guide rails 1, a positioning shell 2, a number of positioning grooves 10, a horizontal conveying mechanism, a vertical lifting mechanism and four supporting feet 25, in:

[0078] The two above-mentioned guide rails 1 are relatively arranged in parallel along the horizontal plane; the above-mentioned positioning shell 2 is erected on the top surface of the two above-mentioned guide rails 1 . The top surface of the positioning shell 2 is provided with several above-mentioned positioning grooves 10, the positioning groove 10 includes a cavity 46, the inside of the cavity 46 is a positioning cavity 47, and the bottom of the cavity 46 is provided with a lower opening 48, the top of the cavity 46 is provided with an upper opening 49, the middle of the cavity 46 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com