Electric stirrer for metal smelting

A stirrer, electrical technology, applied in the direction of stirring device, electric charge control, furnace, etc., can solve the problem of unreachable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

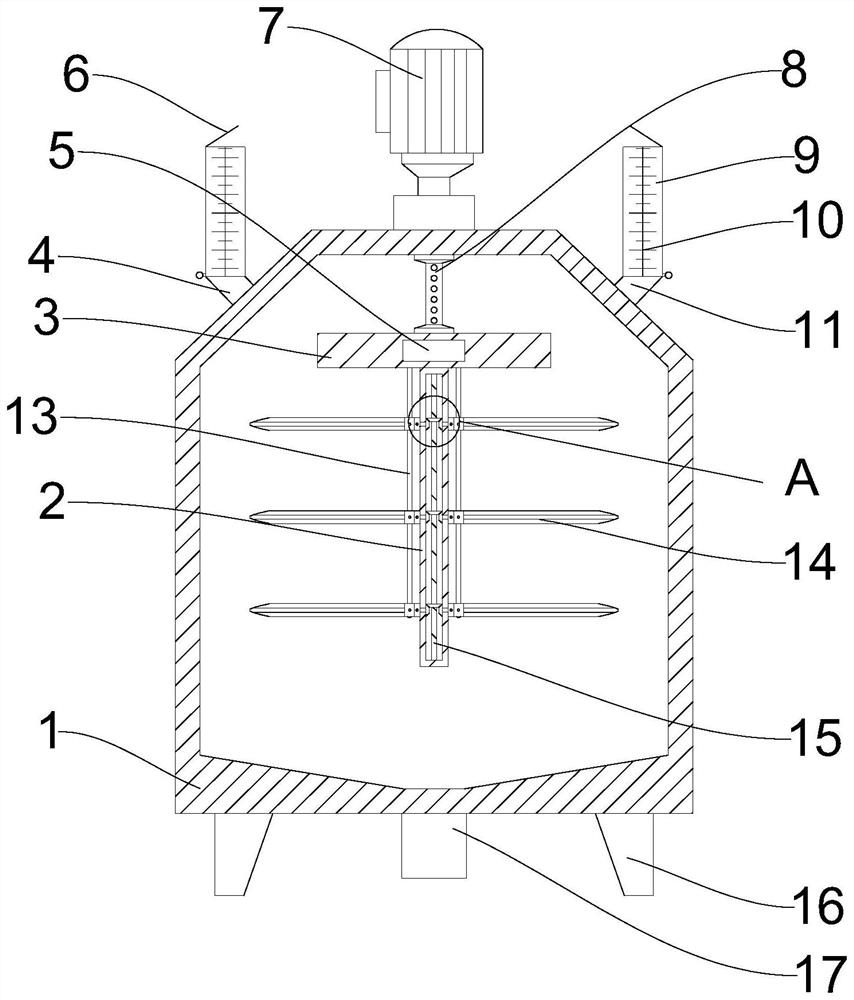

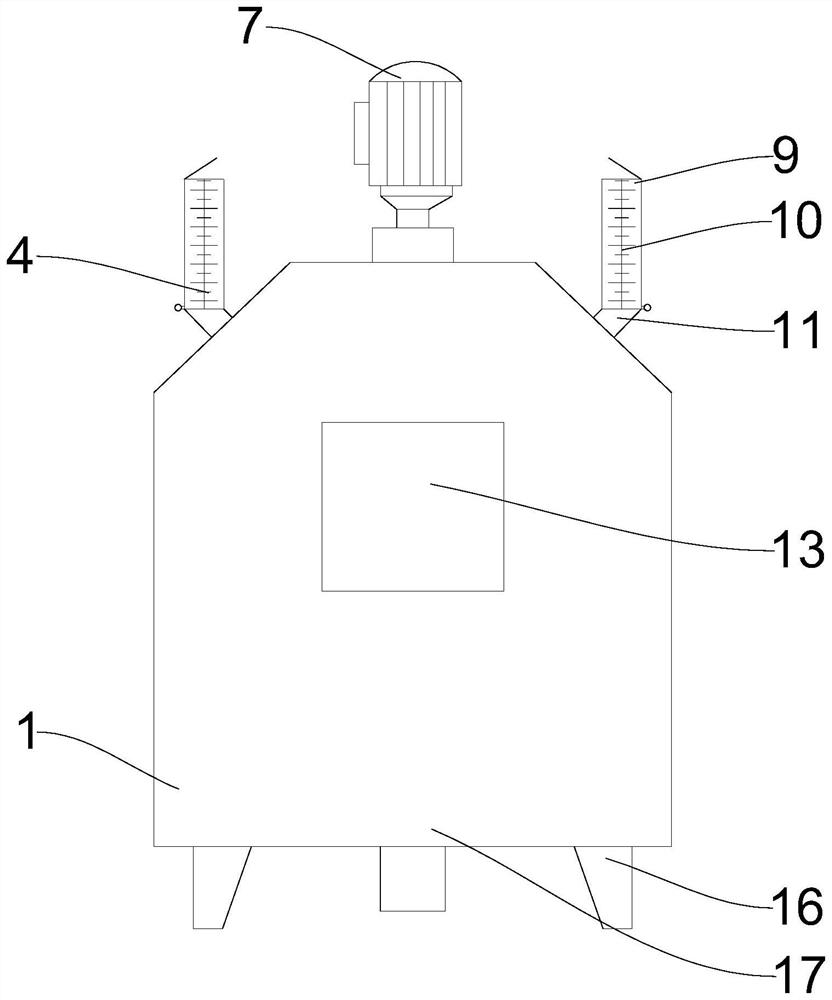

[0041] Please refer to Figure 1-Figure 4 , the present embodiment provides an electric stirrer for metal smelting, including a material mixing furnace 1 and a stirring assembly;

[0042] Above-mentioned material mixing furnace 1 is provided with raw material input port 4, flux input port 11 and discharge port 17, and above-mentioned raw material input port 4 and above-mentioned flux input port 11 are all arranged on the top of above-mentioned material mixing furnace 1, and raw material input port 4 and The flux feeding port 11 is symmetrical about the middle part of the above-mentioned material mixing furnace 1, and the above-mentioned discharge port 17 is arranged at the bottom of the above-mentioned material mixing furnace 1;

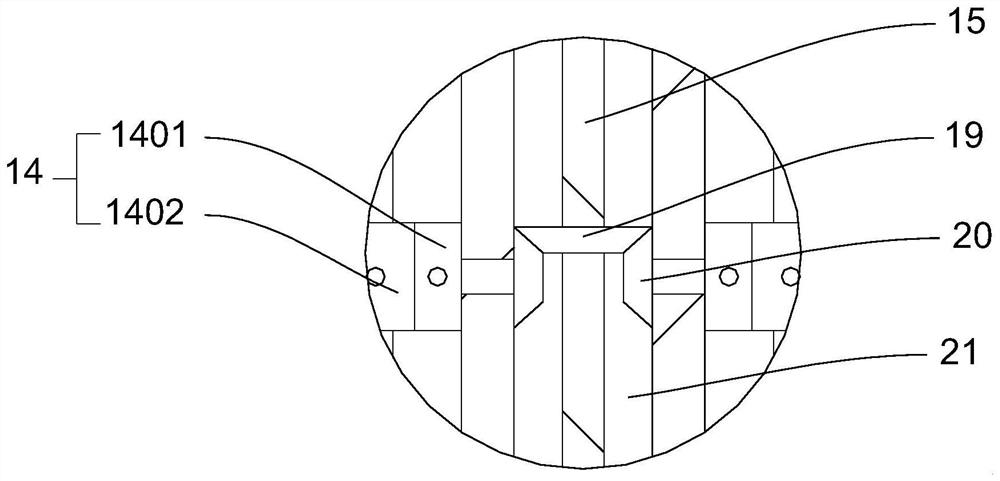

[0043] The stirring assembly includes a connecting seat 3 arranged in the inner cavity of the material mixing furnace 1, a connecting rod 2 is arranged on the lower side of the connecting seat 3, and a stirring blade 14 perpendicular to the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com