Silica gel sealing gasket production cutting device and using method thereof

A sealing gasket and silica gel technology, which is applied in metal processing and other directions, can solve problems such as difficult visual observation, affecting processing and production, and high labor intensity, and achieve the effects of facilitating subsequent processing and production, high cutting efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

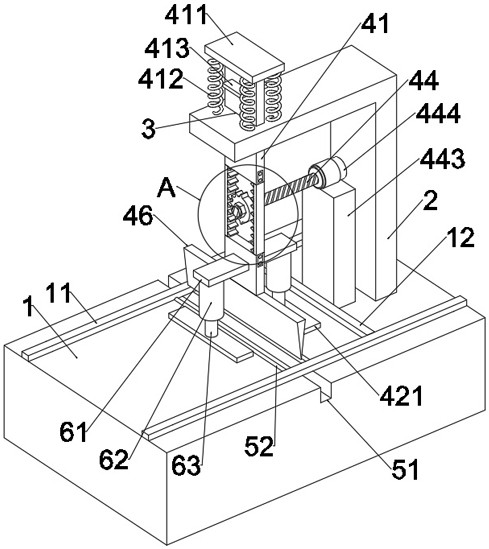

[0035] The present invention provides such as Figure 1-5 The shown a kind of silica gel gasket production and cutting device comprises an operation table 1, an L-shaped plate 2 is connected to one side of the top of the operation table 1, and a chute 3 is opened on the top of the L-shaped plate 2. There is a cutting mechanism inside the chute 3;

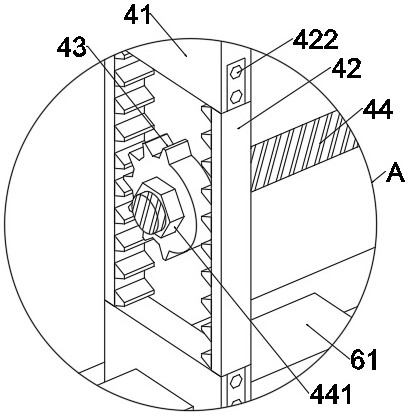

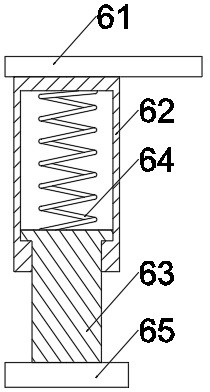

[0036] Described cutting mechanism comprises upper board body 41, and described upper board body 41 is connected with L-shaped board 2 through chute 3, and described upper board body 41 bottom front and rear sides are all connected with rack 42, two racks 42 There are incomplete gears 43 that can mesh with each other, and the incomplete gears 43 are internally connected with a rotating shaft 44. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com