Assembly method of interference fit steel ring structural member

An assembly method and interference fit technology, applied in the field of aerospace, can solve the problems of high cost, difficult assembly, difficulty in coping with the speed of aerospace technology, etc., achieve strong field applicability and avoid low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

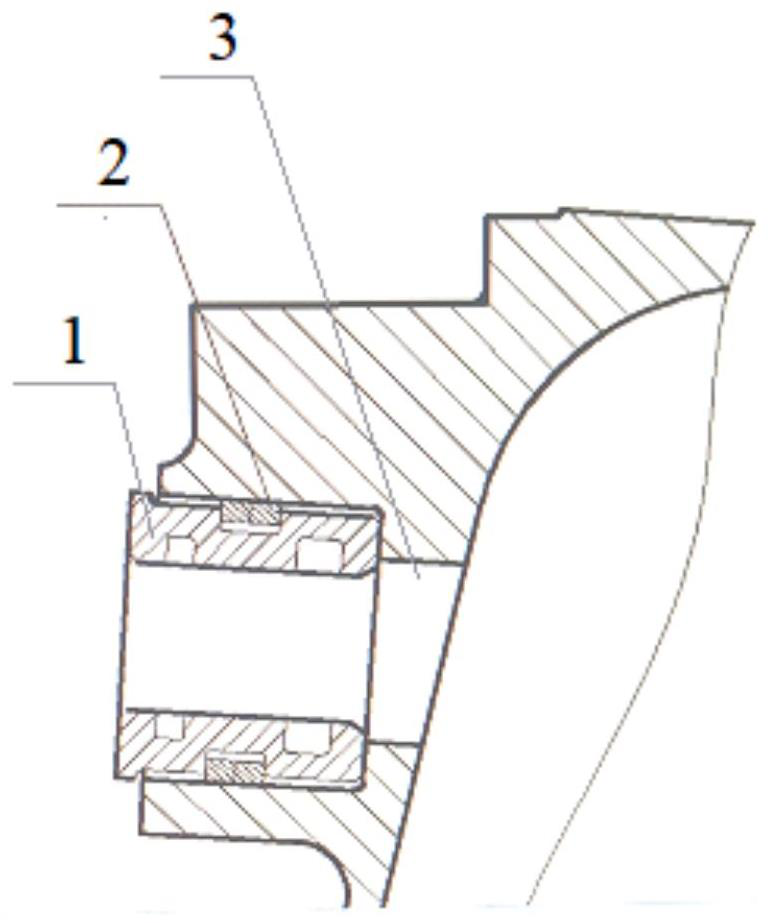

[0019] This embodiment specifically provides an assembly method for the interference fit steel ring structure. According to the size of the snap ring, select the appropriate needle-nose pliers and wrench, and generally choose the same size.

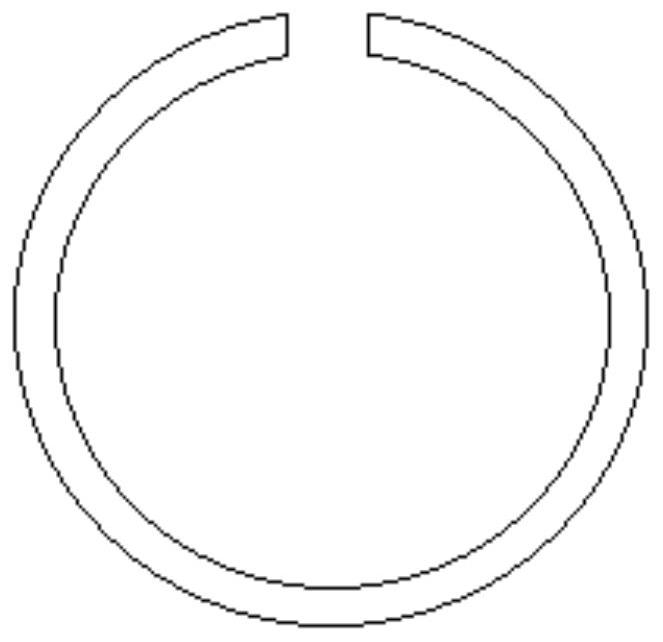

[0020] Place the elastic open steel ring on the snap ring, use needle-nose pliers to split the steel ring, fit the steel ring on the snap ring, and use a wrench to assist in pressing the steel ring. After the steel ring is assembled to the boss of the snap ring, use Tap the steel ring into the groove in the snap ring with needle nose pliers and / or a wrench.

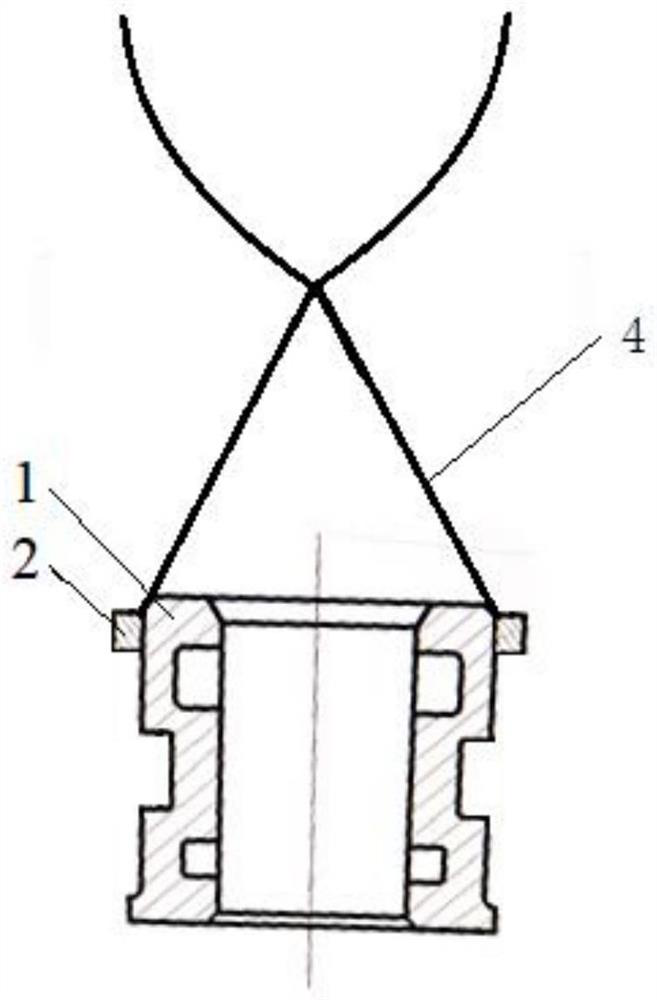

[0021] Use the chuck of the hand electric drill to clamp the steel ring of the snap ring to complete the installation step, so that the steel ring is on the same plane as the outer surface of the open ring; insert the mounting end of the snap ring in the clamped state into the matching hole, and at the same time the chuck and the outer surface of the open ring are on the same plane; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com