High-voltage cable joint protection device

A protection device and high-voltage cable technology, which is applied in the direction of cable joints and electrical components, can solve the problems of inconvenient on-site use, poor sealing of the protection box, and reduced work efficiency of the staff, so as to achieve strong on-site applicability and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

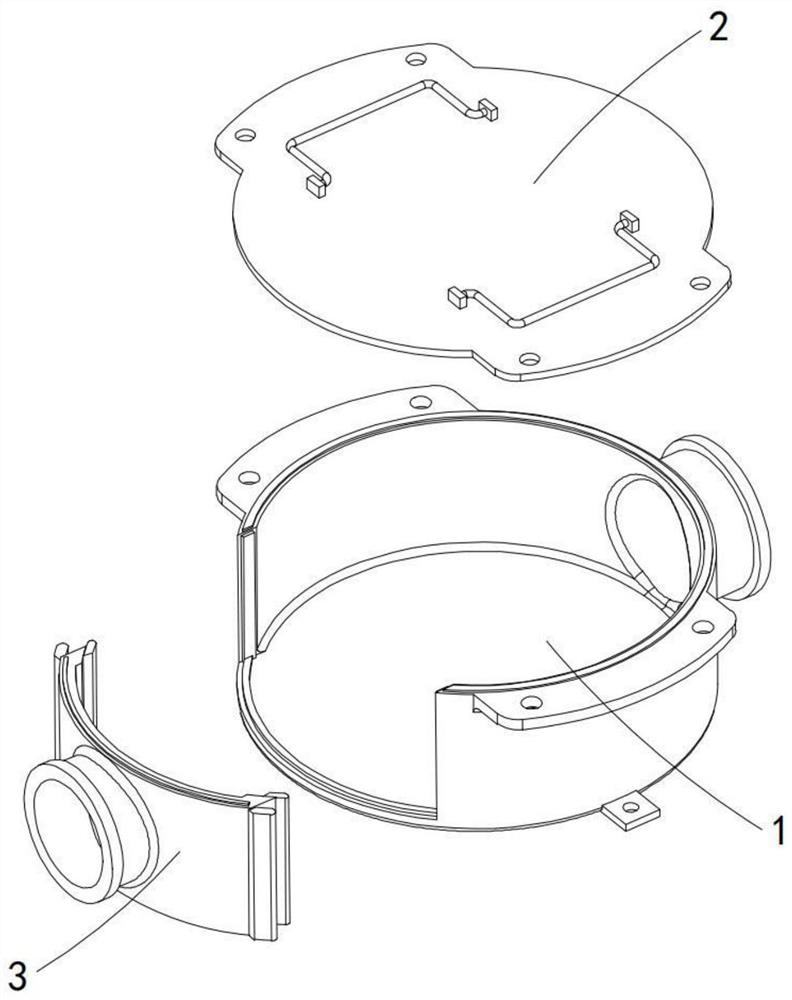

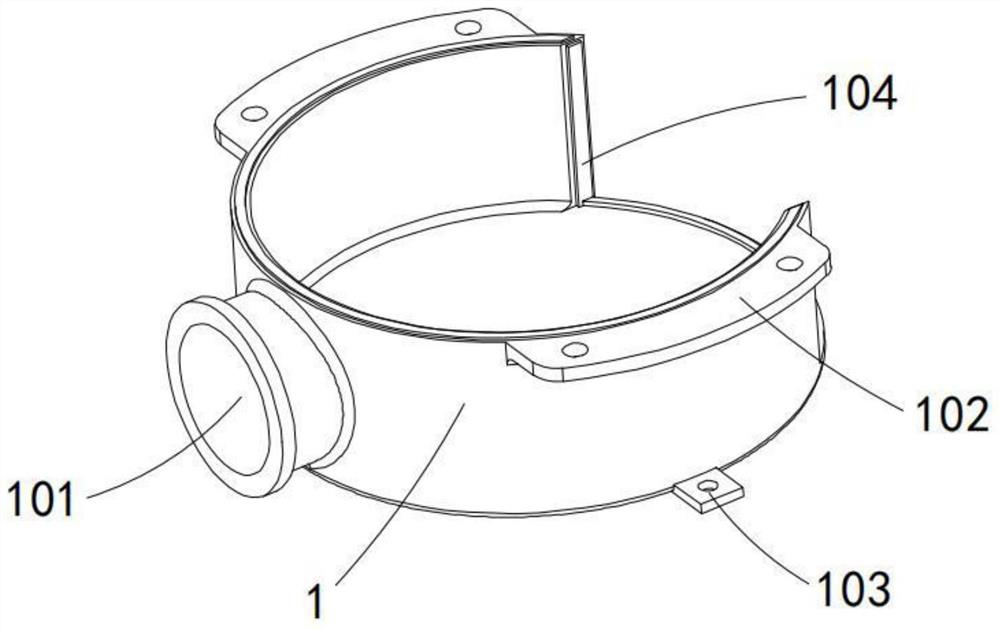

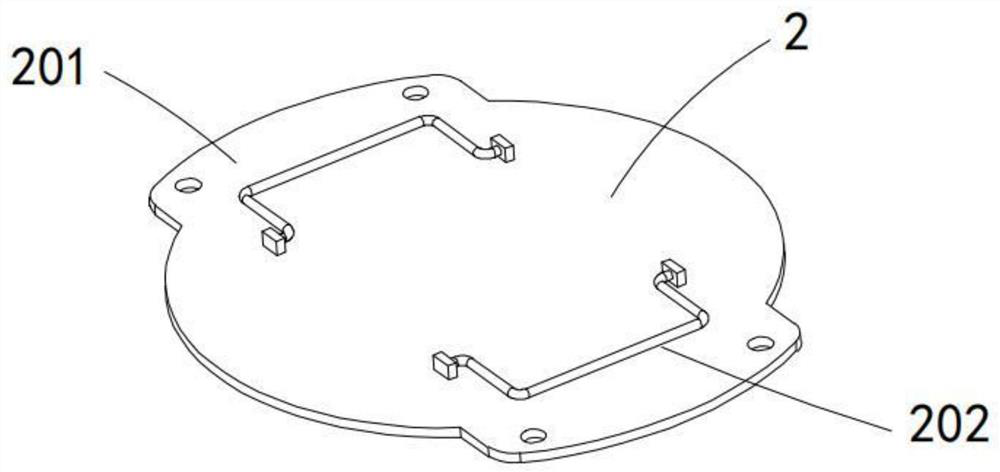

[0029] Such as Figure 1 to Figure 6 As shown, a high-voltage cable joint protection device according to the present invention adopts a technical solution that includes a protective shell 1 and a protective cover 2, and shell fastening plates 102 are provided on both sides of the upper edge of the protective shell 1 , the two sides of the edge of the protective cover 2 are provided with cover body fastening plates 201, and the edge of the protective shell 1 is provided with a plurality of sections of shell sealing rings 105, and the protective shell 1 and the protective cover 2 are detachably connected. A first joint seat 101 is provided on one side of the protective case 1, and a replacement slot 104 is opened on the other side of the protective case 1, and the inner side of the replacement slot 104 can be plugged with a joint seat assembly 3 for replacement. Component 3 is used to coordinate and fix single or multiple high-voltage cable heads. The protective shell 1 and prot...

Embodiment 2

[0035] Such as Figure 7 and 8 As shown, the difference from Embodiment 1 is that two symmetrically arranged joints 306 are connected to the outside of the replacement plate 301, and the outside of the joints 306 is fixed with a clamp to form a three-way protective box. Seat assembly 3 is suitable for tee joint form.

Embodiment 3

[0037] Such as Figure 9 As shown, the difference from Embodiment 1 is that a connecting seat 307 is provided on the outer edge of the connector 306, and the connecting seat 307 is connected to the cable connector through bolts, so that the protective box device is suitable for cables with bolted connectors.

[0038] When in use: the staff carries the protective shell 1, the protective cover 2 and different joint seat assemblies 3 to the construction site, selects the joint seat assembly 3 according to the number of on-site cable joints and the form of the joint seat, and passes the joint seat assembly 3 through the replacement slot 104 and The protective shell 1 is sealed and connected, and the sealed cable is installed in place. Select the clamp or cable connector to fix the cable sheath. Cover the protective cover 2 and fix it with screws. The shell sealing ring 105 and the replacement plate sealing ring 303 ensure the protection of the cable joint. The box body is sealed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com