Transmission of mini-tiller

A transmission and micro-tiller technology, which is applied in agricultural machinery, agricultural machinery and implements, agriculture, etc., can solve the problems of high height of the micro-tiller, and achieve the effects of improving light weight, facilitating lubrication, and improving miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

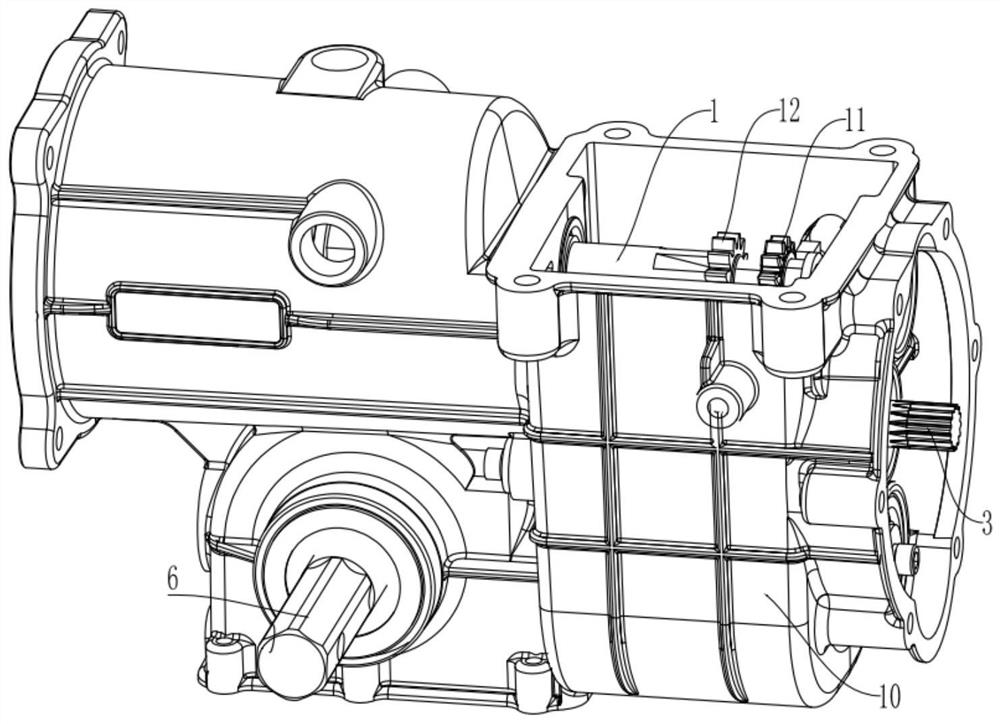

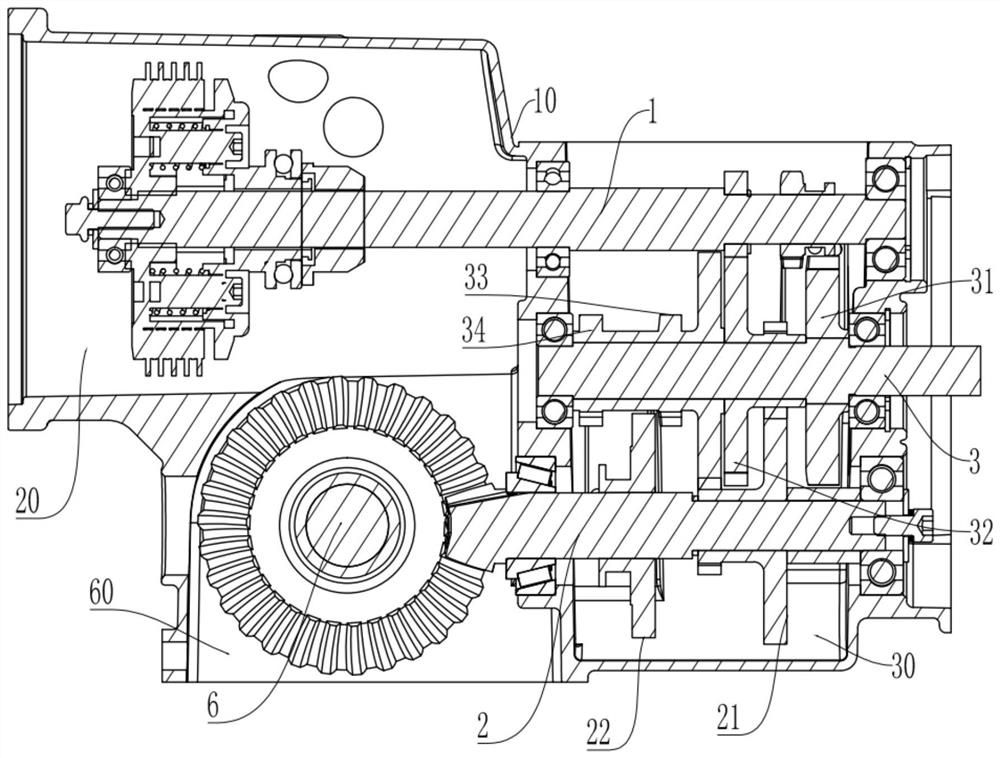

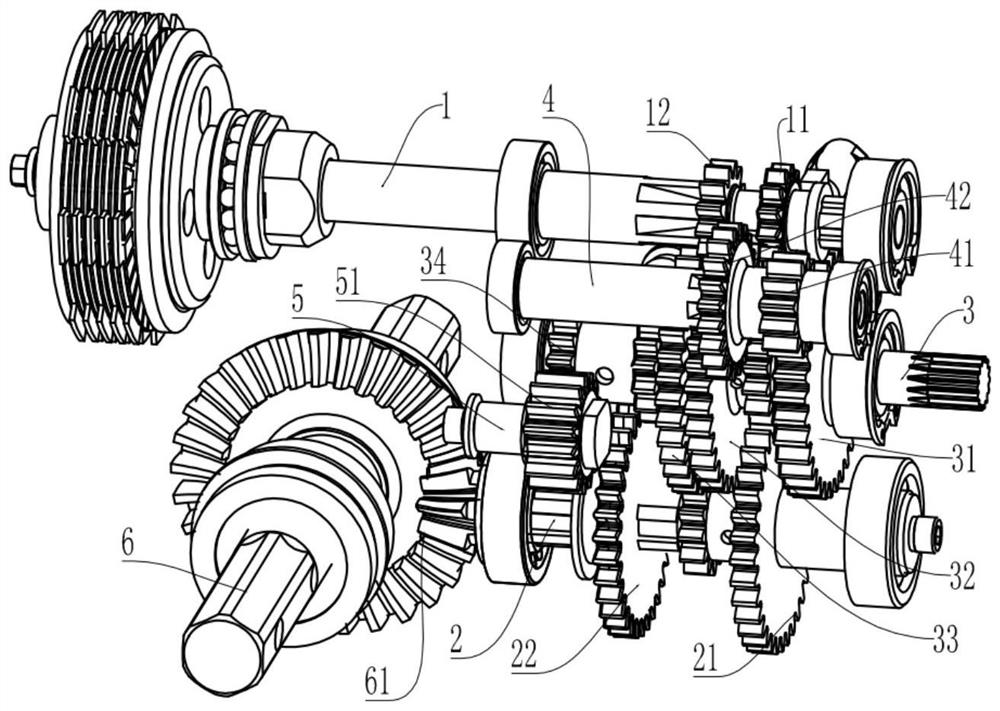

[0038] The embodiment is basically as attached figure 1 As shown, the tiller transmission includes a casing 10 and a transmission system located in the casing 10. The casing 10 includes a clutch chamber 20, a speed change chamber 30 and a travel chamber 60 that communicate with each other. The clutch chamber 20 and the travel chamber 60 are located at On the same side of the transmission chamber 30, the clutch chamber 20 is used to accommodate the clutch, and the transmission chamber 30 is used to accommodate transmission parts of the transmission system.

[0039] The transmission system includes the main shaft 1, the travel output shaft 2, the tool output shaft 3, the intermediate shaft 4 and the reverse gear shaft 5 that are rotatably connected to the chamber wall of the transmission chamber 30. The main shaft 1 is axially slidably connected with a shift gear 11, and the tool output A fixed gear 31 is fixedly connected to the shaft 3, and a transition gear set is set on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com