Hole position degree auxiliary testing fixture

A technology of hole position degree and inspection tool, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of inconvenient on-site quality control, long inspection period, product quality out of tolerance, etc., to reduce the probability of product out of tolerance. , The detection process is simple, and the effect of optimizing the detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

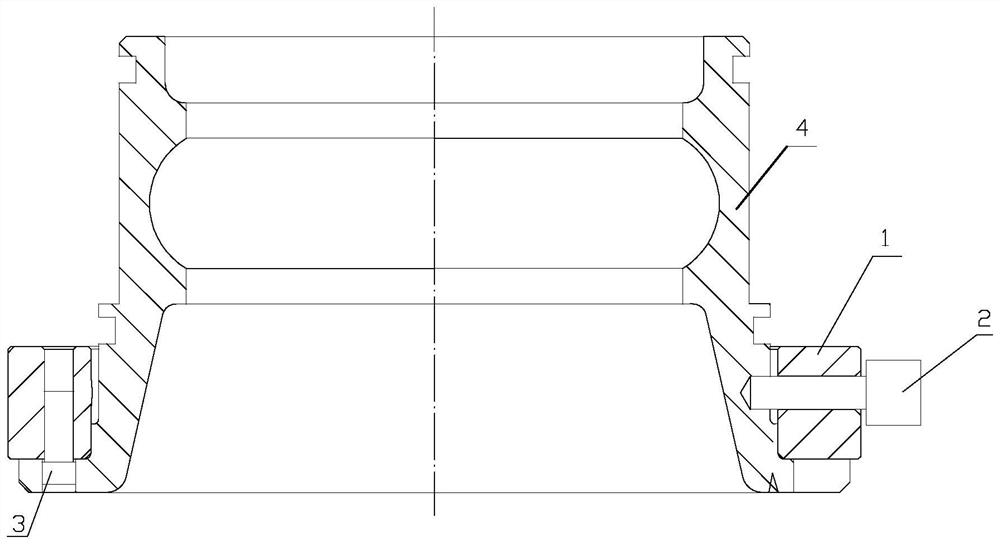

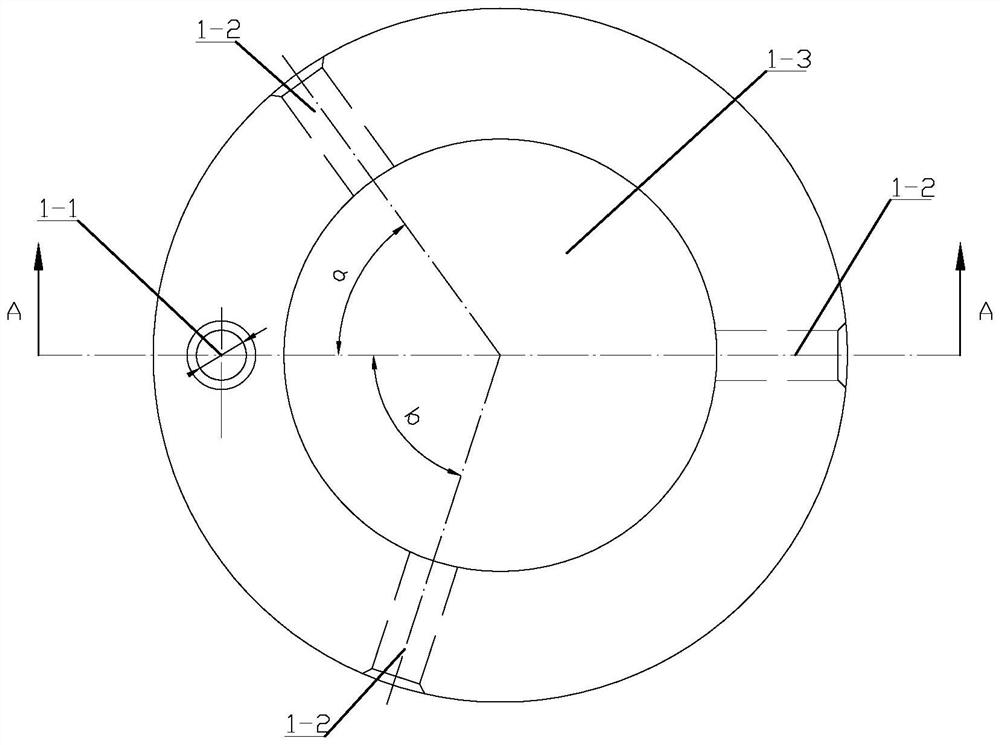

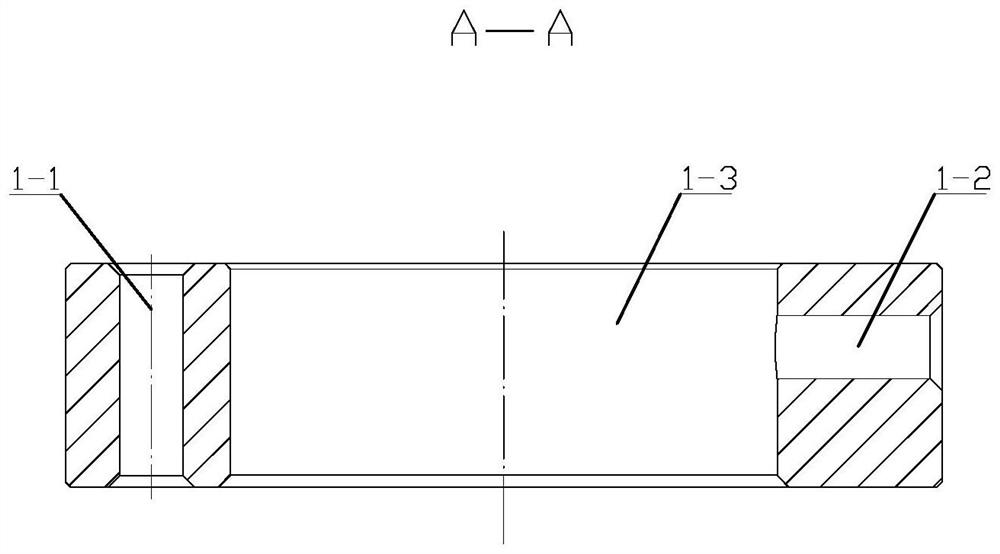

[0016] Combine below Figure 1 to Figure 3 And further illustrate the technical scheme of the present invention by specific embodiment:

[0017] An auxiliary inspection tool for hole position, including a base 1, positioning pins 3 and three pins 2, the base 1 is a cylindrical structure, the center of the base 1 is provided with a set of holes 1-3, and the bearing method The reference outer diameter of the blue plate is matched, the base 1 is set on the bearing flange 4 through the sleeve hole 1-3, the inner diameter of the sleeve hole 1-3 is equal to the outer diameter of the bearing flange 4, along the edge of the base 1 There is a first positioning hole 1-1 in the axial direction of the base 1. The first positioning hole 1-1 matches the positioning hole on the bearing flange 4, and the positioning pins 3 pass through the bearing flange 4 in turn. The positioning hole and the first positioning hole 1-1 on the base play the role of positioning, preventing the base and the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com