A high-quality freeze-dryer and freeze-drying process for reducing internal voids of raw materials

A high-quality, freeze-drying technology, applied in the field of freeze-drying machines, can solve problems such as voids in raw materials, affecting sensory quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

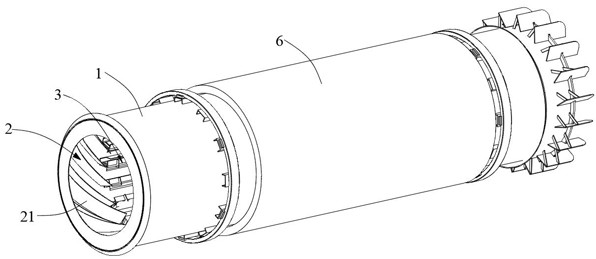

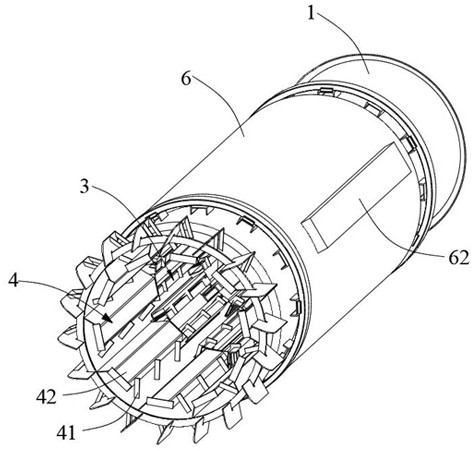

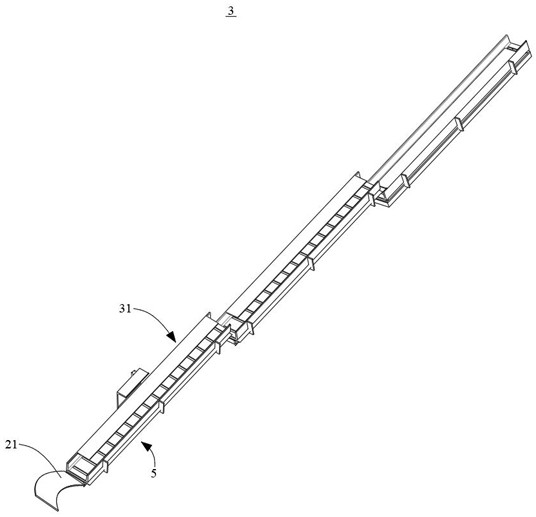

[0032] like Figure 1 to Figure 9 As shown, this embodiment provides a high-quality freeze dryer that reduces the internal voids of raw materials, including a drum body 1, which can rotate and vacuumize after quick freezing. Specifically, the drum body 1 has a drive motor outside, The track on the outer wall of the drum body 1 is driven by the driving motor to rotate the drum body 1. Door panels are respectively provided at the inlet end and the outlet end of the drum body 1, and a compressor is also provided outside the drum body 1. After the two door panels are closed, the The compressor refrigerates the inside of the drum body 1 to freeze the moisture in the raw material in the drum body 1. A vacuum pump is also provided outside the drum body 1, and the air in the drum body 1 is evacuated by the vacuum pump, so that the Ice sublimation becomes freeze-dried; in order to realize the orderly entry of raw materials into the drum body 1, a feeding part 2 is provided at the inlet...

Embodiment 2

[0053] This embodiment 2 also provides a freeze-drying process of a high-quality freeze-drying machine that reduces the internal voids of the raw materials, and the structure of the high-quality freeze-drying machine that reduces the internal voids of the raw materials is the same as that of the embodiment 1, and will not be repeated here. .

[0054] A specific freeze-drying process of a high-quality freeze-drying machine that reduces internal voids in raw materials is as follows: when the discharging slide rail 311 rotates from the "twelve o'clock" position to the "six o'clock" position, the pre-freezing box 53 is located in the discharging position. Above the slide rail 311; by sliding the pre-freezing sliding plate 54 against the discharging slide rail 311, the pre-freezing plug 57 is released from the pre-freezing groove 531, so that the dry ice is poured out to the pre-freezing guide plate 56 and the pre-freezing guide plate 56 and the pre-freezing groove 531. Between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com