Adjusting support of surge shaft fast door laser range finder and manufacturing method

A technology of laser rangefinder and bracket adjustment, which is applied in the direction of machine platform/bracket, support machine, final product manufacturing, etc. It can solve the problems of inconvenient angle adjustment, achieve rapid and accurate angle adjustment, and quickly and accurately measure the opening of fast doors , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

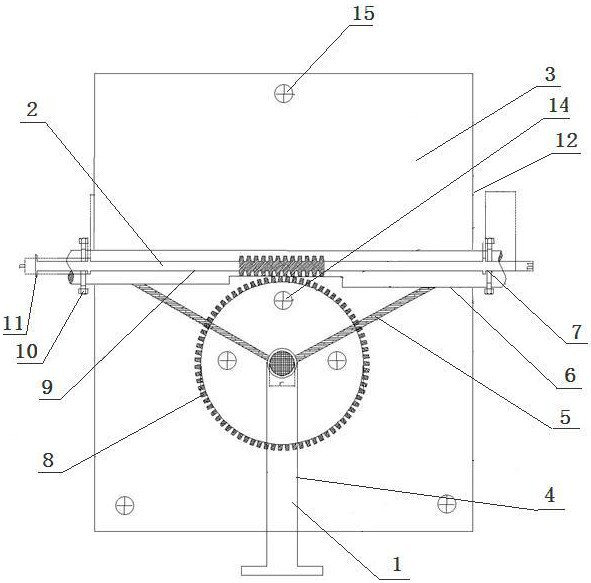

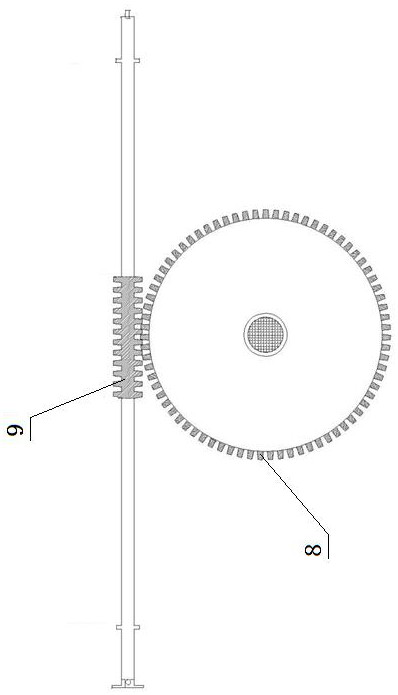

[0035] An adjustment bracket of a laser rangefinder for a fast door of a surge well, which consists of: a fixed bracket 1, an adjustment transmission mechanism 2, and a rangefinder fixing plate 3, the fixed bracket includes a bracket crank arm 4, and the The bottom of the bracket crank arm is connected to the base, the top of the bracket crank arm is connected to the sleeve 6 through the triangle bracket 5, the bottom of the sleeve has a rectangular opening, and the adjustment transmission mechanism includes a worm wheel 8. The worm wheel and the worm 9 are engaged in the rectangular opening, the worm is fixed in the sleeve, and are limited by stop screws 10 at both ends, and the worm wheel is installed on the bracket corner on the arm and fixed with the fixed plate by bolts.

Embodiment 2

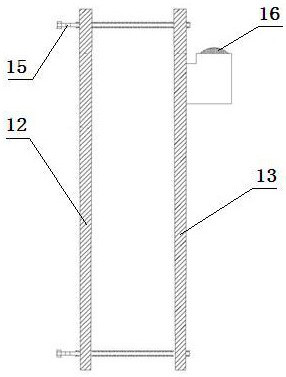

[0037] According to the adjustment bracket of the laser rangefinder of the fast door of the surge shaft described in Embodiment 1, the fixed plate of the rangefinder includes an inner plate 12, and the inner plate passes through the worm wheel and the bracket The crank arm is connected, the inner layer board is connected with the outer layer board 13 through three adjusting screws 15, the side wall of the outer layer board is equipped with a bubble level 16, and the inner layer board is connected with three follower screws 14 Connected with the bracket arm, the two ends of the worm are equipped with operating handles 11 .

Embodiment 3

[0039] According to the adjustment bracket of the laser rangefinder for the fast door of the surge shaft described in Embodiment 1, there are four limit holes 7 on both sides of the sleeve for installing the limit screws, and the bracket arm There is a 60° inclination angle structure between the tripod and the tripod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com