Marine three-section folding vehicle springboard structure

A technology for vehicle springboards and springboards, applied in ship accessories, passenger handling equipment, ships, etc., can solve problems that affect the realization of the original function, affect the use of other decks, affect the appearance, etc., and achieve the effect of good use safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

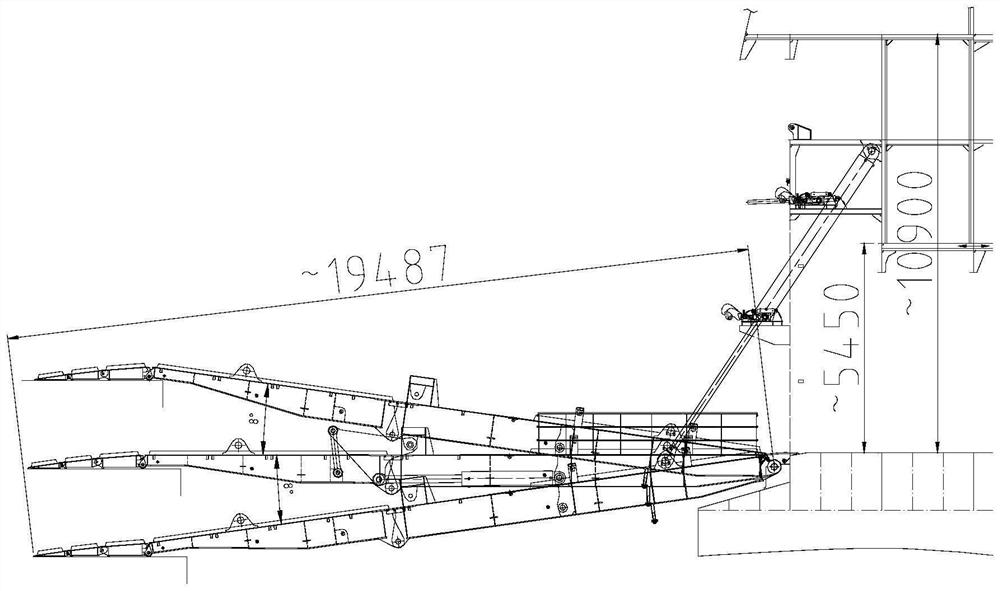

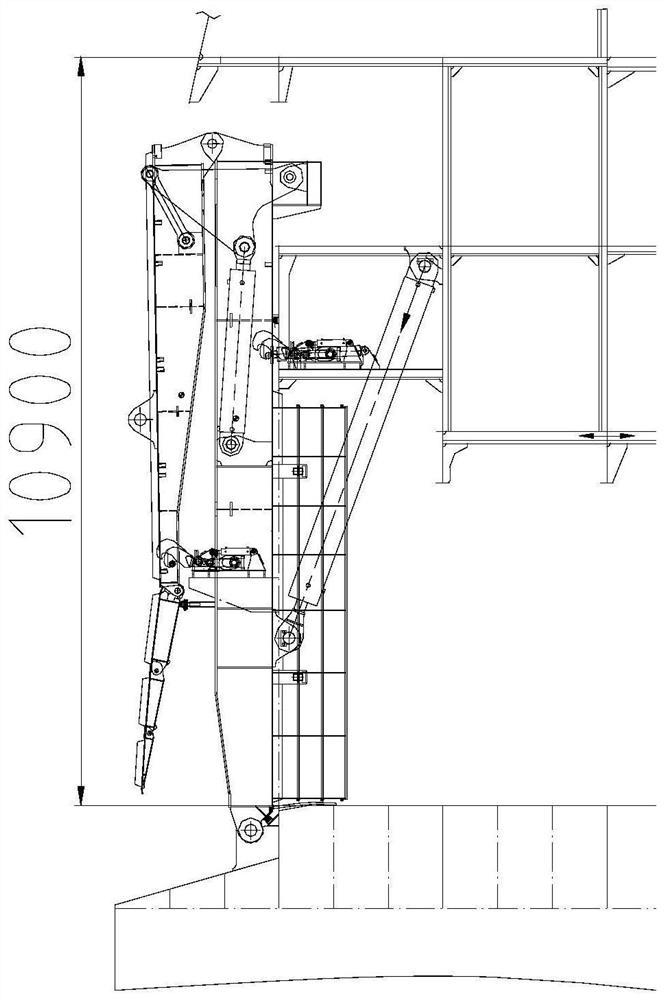

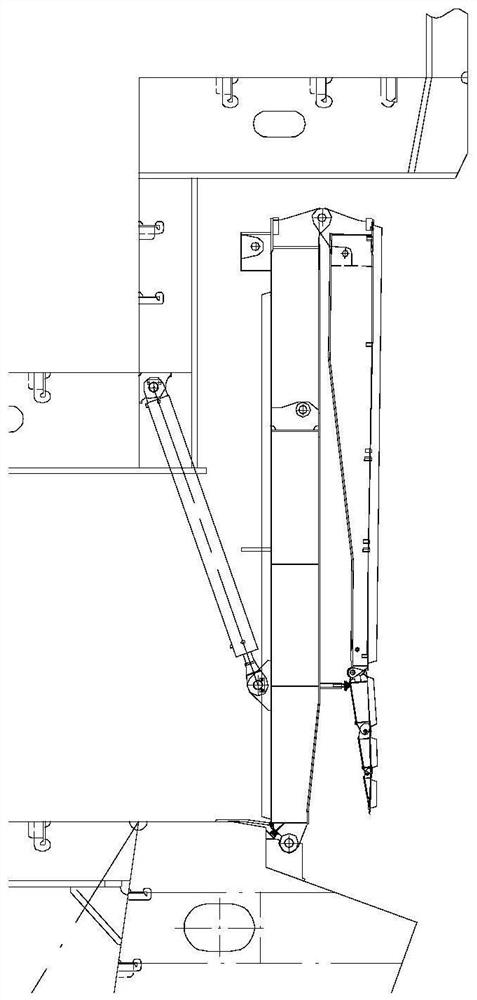

[0037] See Figure 4 to Figure 7 As shown, in the embodiment of the present invention, a marine three-section folding vehicle springboard structure is shown, including: top deck 01, roll-off deck 02, hull member 03, first section springboard 11, second section springboard 12, first section springboard 12, Three-section springboard 13, one-section wing plate 14, connection mechanism one 15, connection mechanism two 16, connection mechanism three 17, steel baffle plate 18, wire rope winch 21, second support wire rope 22, first support cylinder 23, connection mechanism Four 24, wharf plane 31.

[0038] The ro-ro deck 02 is fixedly connected with the hull member 03, the top of the hull member 03 is fixedly connected with the top deck 01, the bottom surface of the top deck 01 is equipped with a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com