Judgment grading device for large-leaf crops

A grading device and crop technology, applied in the field of visual inspection of automated equipment, can solve problems such as misclassification, too late swinging time, and tilting of large-leaf crops, and achieve the effects of reducing costs, increasing production capacity, and unifying positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will now be described in further detail with reference to the accompanying drawings and preferred embodiments. These figures are schematic diagrams, which will be described only in a schematic manner, and therefore it only shows the configurations related to the present invention.

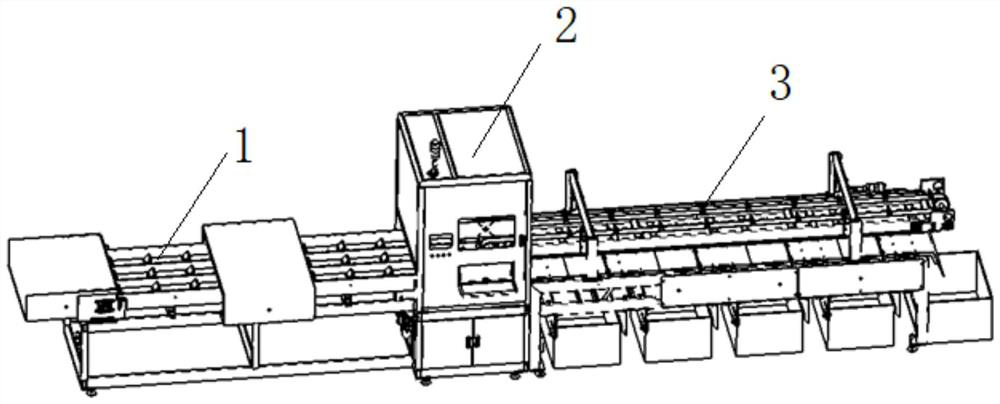

[0028] Such as Figure 1 - Figure 8 A determination grading device for the big leaf crop, the device is used based on the visual detection of the chipper.

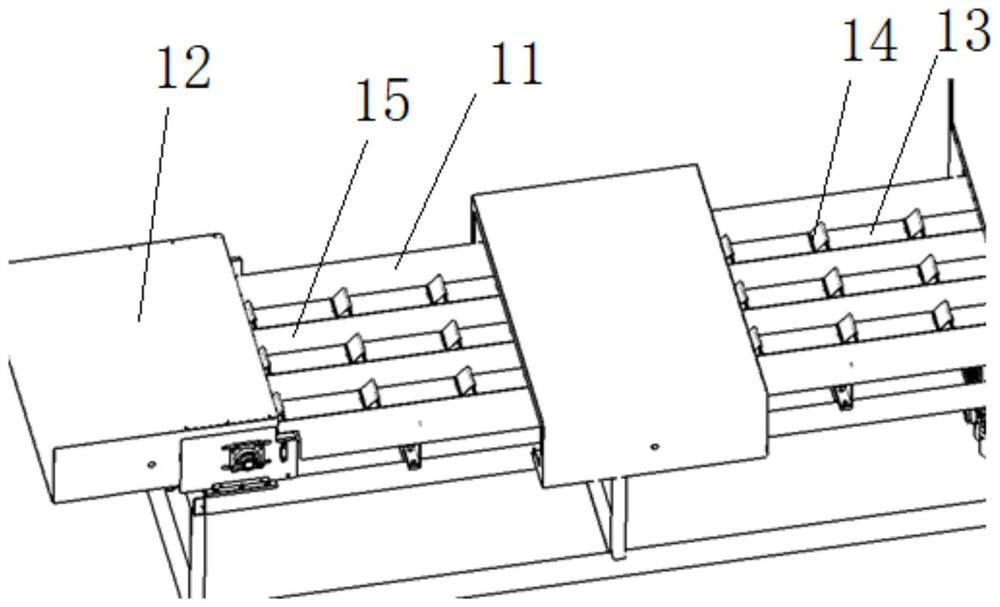

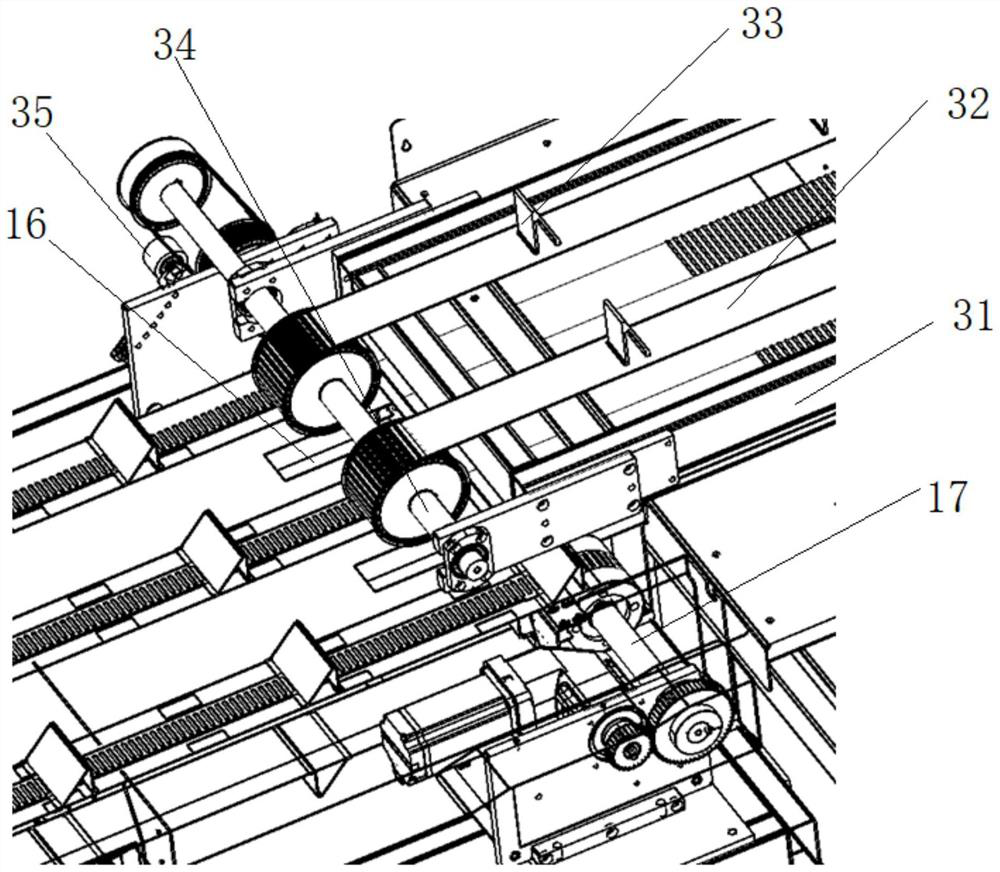

[0029] The device includes the artificial upper material module 1, the visual detection module 2, and the dial binding binding station group 3, which are sequentially provided; the large leaf crop 5 is transmitted to the visual detection module 2 by the artificial upper module 1, and the detection is completed. After the baffle, the die-binding group 3 is passed through the large leaf crop 5 and the large leaf crop 5 is transmitted to the corresponding grade warehouse.

[0030] Such as figure 2 As shown, the artificial u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com