Beta-Ni (OH) 2 nanosheet array electrode material growing on large-size foamed nickel in situ and application of beta-Ni (OH) 2 nanosheet array electrode material

A nanosheet array, in-situ growth technology, used in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, electrolytic capacitors, etc. degree of agglomeration, large size, large capacity and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

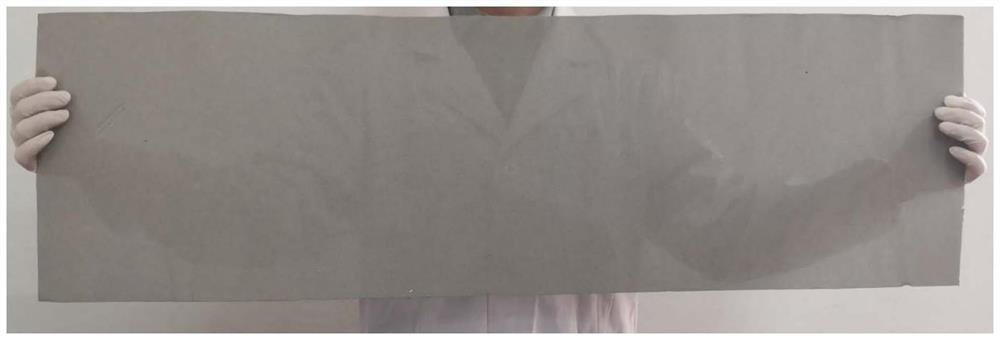

[0057] 1. Prepare large-sized nickel foam (length 100cm×width 30cm×thickness 0.16cm) for use, such as figure 1 Shown, the quality of this moment nickel foam is about 33.4g;

[0058] 2. 346g (206mL) mass fraction of 85% H 3 PO 4 The solution was added dropwise to 2794mL deionized water, stirred magnetically for 10 minutes, and prepared into 1MH 3 PO 4 solution;

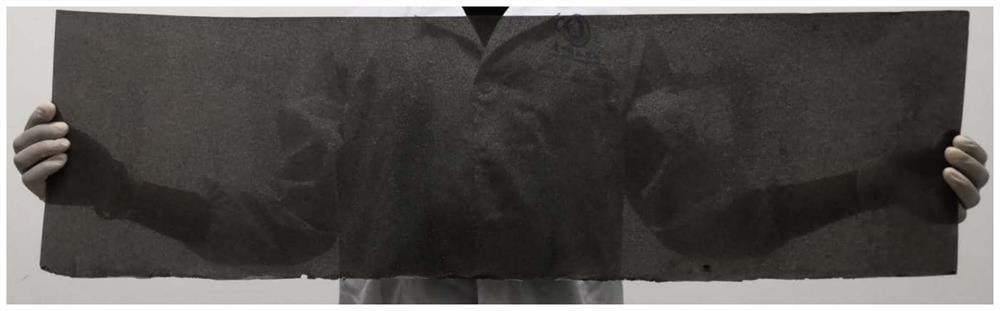

[0059] 3. Curl the nickel foam and immerse it in 1M H 3 PO 4 solution, etched at room temperature (about 22°C) for 15 hours, took out the etched nickel foam and dried it naturally at room temperature to obtain Ni foam formed on the surface. 3 (PO 4 ) 2 Precursors of nickel foam, such as figure 2 shown;

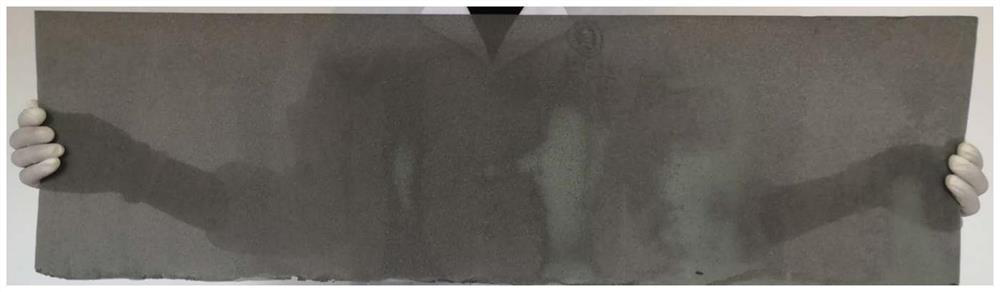

[0060] 4. At room temperature, generate Ni on the surface 3 (PO 4 ) 2 The nickel foam of the precursor is crimped and soaked in 4M KOH solution for 20 hours, and the soaked nickel foam is taken out and dried naturally at room temperature to obtain β-Ni(OH) grown in situ on the large-sized nickel foam. 2 ...

Embodiment 2

[0074] 1. Prepare large-sized nickel foam (length 100cm×width 30cm×thickness 0.16cm) for use. At this time, the mass of foam nickel is about 33.4g;

[0075] 2. 34.5g (20.7mL) of 85% H 3 PO 4 The solution was added dropwise to 2979.3mL deionized water, stirred magnetically for 10 minutes, and prepared into 0.1M H 3 PO 4 solution;

[0076] 3. Curl the nickel foam and immerse it in 0.1M H 3 In PO4 solution, at room temperature (about 2 ℃, etch 15h, take out the foamed nickel after etching and dry naturally at room temperature, obtain the surface and generate Ni 3 (PO4) 2 Precursor nickel foam;

[0077] 4. At room temperature, generate Ni on the surface 3 (PO4) 2 The nickel foam of the precursor is crimped and soaked in 4M KOH solution for 20 hours, and the soaked nickel foam is taken out and dried naturally at room temperature to obtain β-Ni(OH) grown in situ on the foam nickel. 2 Nanosheet array electrode material, after acid etching and alkali soaking, the loading capa...

Embodiment 3

[0084] 1. Prepare large-sized nickel foam (length 100cm×width 30cm×thickness 0.16cm) for use, and the mass of foam nickel is about 33.4g for use;

[0085] 2. 346g (206mL) mass fraction of 85% H 3 PO 4 The solution was added dropwise to 2794 mL of deionized water, stirred magnetically for 10 minutes, and prepared into 1M H 3 PO 4 solution;

[0086] 3. Curl the nickel foam and immerse it in 1M H 3 PO 4 solution, etched at room temperature (about 22°C) for 15 hours, took out the etched nickel foam and dried it naturally at room temperature to obtain Ni foam formed on the surface. 3 (PO 4 ) 2 Precursor nickel foam;

[0087] 4. At room temperature, generate Ni on the surface 3 (PO 4 ) 2 The nickel foam of the precursor is crimped and soaked in 4M KOH solution for 5 hours, and the soaked nickel foam is taken out and dried naturally at room temperature to obtain β-Ni(OH) grown in situ on the large-sized nickel foam. 2 Nanosheet array electrode material, after acid etching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com