Technology for improving flatness of fusion zone

A technology of flatness and fusion, applied in multilayer circuit manufacturing, electrical components, printed circuit manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

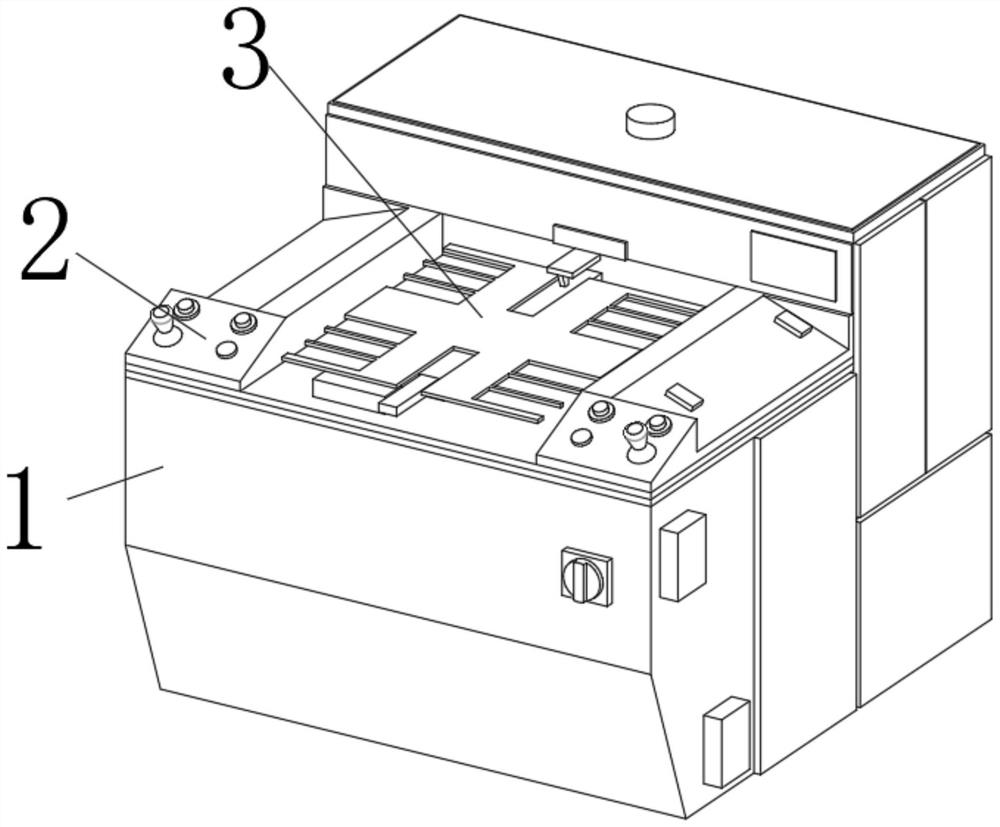

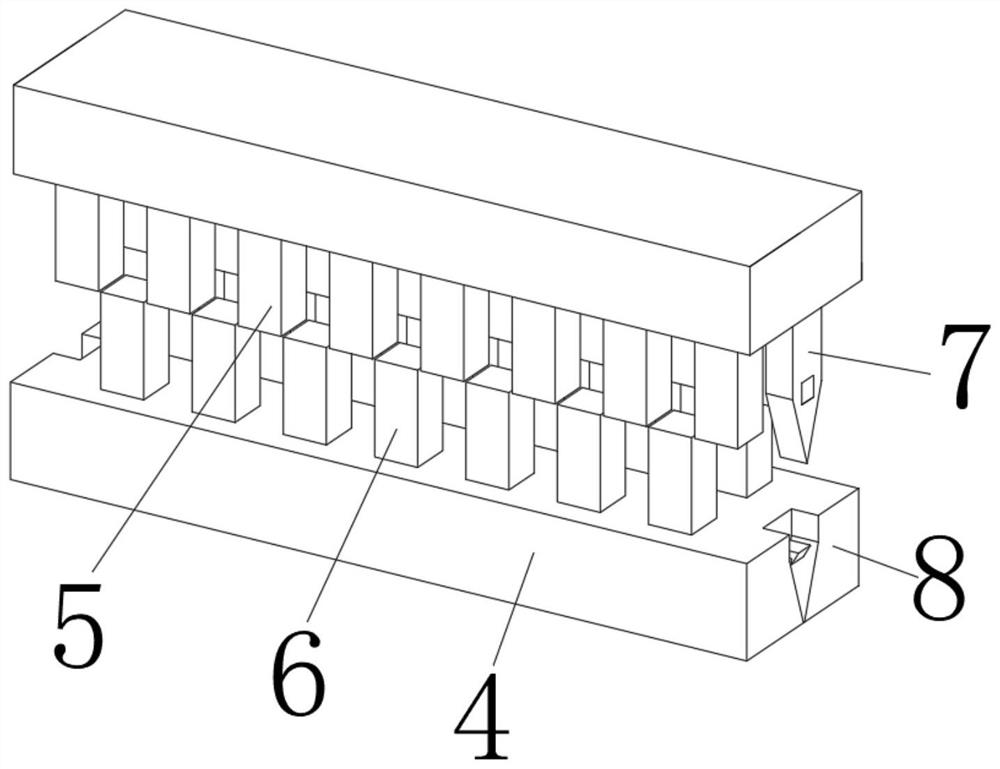

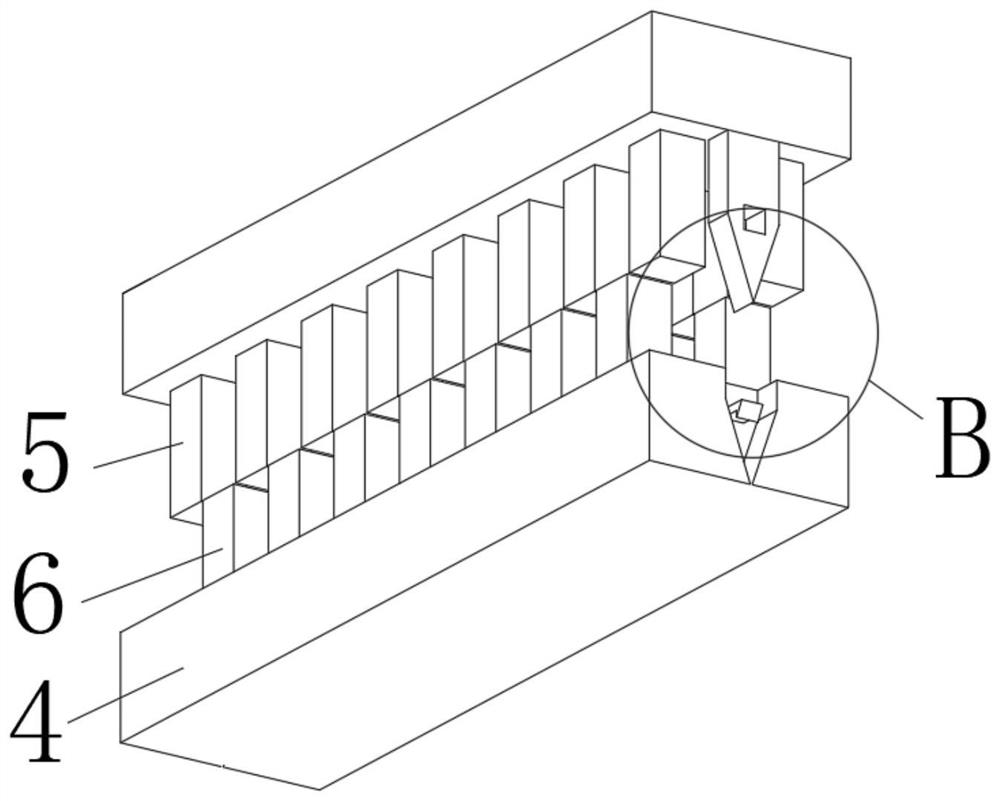

[0028] see Figure 1-4 , the present invention provides a technical solution: a device for improving the flatness of the fusion zone, including a body 1 and two copper blocks 4, and the two copper blocks 4 are fixedly installed inside the body 1, and the body 1 A console 2 and an operating table 3 are fixedly installed on the top, and the sides of the two copper blocks 4 close to each other are fixedly connected to the first slider 5 and the second slider 6 respectively, and the first slider 5 and the second slider The blocks 6 are evenly distributed on the surface of the two copper blocks 4, the first slider 5 and the second slider 6 are staggered and slidably installed with each other, and the side of the copper block 4 close to the first slider 5 is fixed A block 9 is installed, and the inside of the copper block 4 is provided with a chute 8, and the inner wall of the chute 8 is fixedly connected with a block 9, and the inside of the block 9 is provided with a fitting that ...

Embodiment 2

[0031] like Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the bottom end of the plug-in block 7 is slidingly connected with the inside of the chute 8, and there are at least two plug-in blocks 7, and the two plug-in blocks 7 are made of copper block 4 The distribution is axisymmetric, and the dimensions on the surface of the insert block 7 are compatible with those of the inner wall of the chute 8.

[0032] In this embodiment, when the first slider 5 is pressed down, the inserted block 7 is inserted into the chute 8 to limit the position, and the first slider 5 and the second slider 6 are controlled by the plug 7 and the chute 8. Auxiliary alignment to avoid the current generated by the copper block 4 in the high-frequency magnetic field. Once the position of the two copper-free PADs deviates, it will easily lead to damage to the body 1 and materials, and increase the risk of operation. Two The clamping block 9 is stu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com