Visual detection method for motor

A technology of visual inspection and detection method, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means. It can solve problems such as missing labels, missing tapping of large shells, and leakage of motor claws, etc., and achieves high speed. Fast, long working time, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

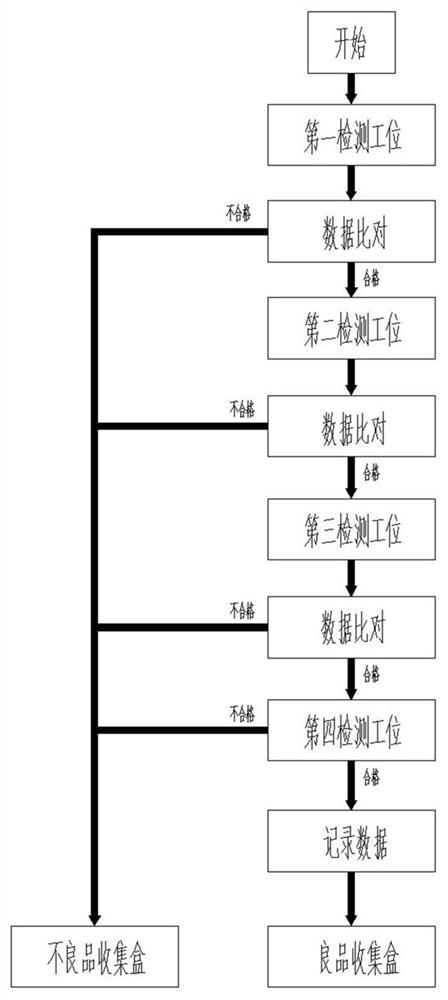

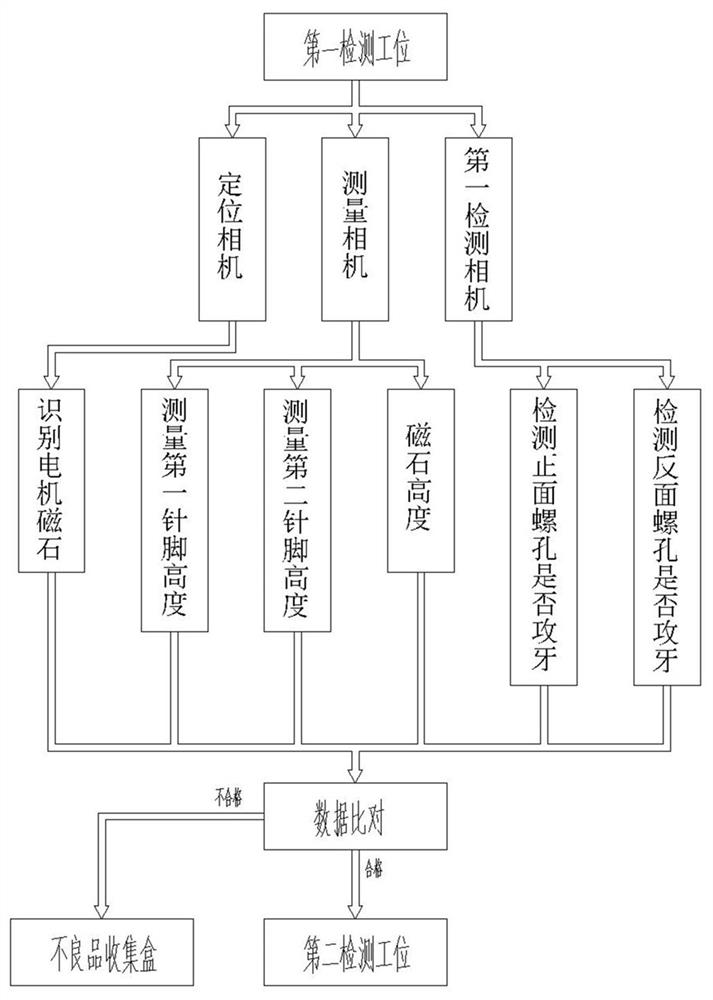

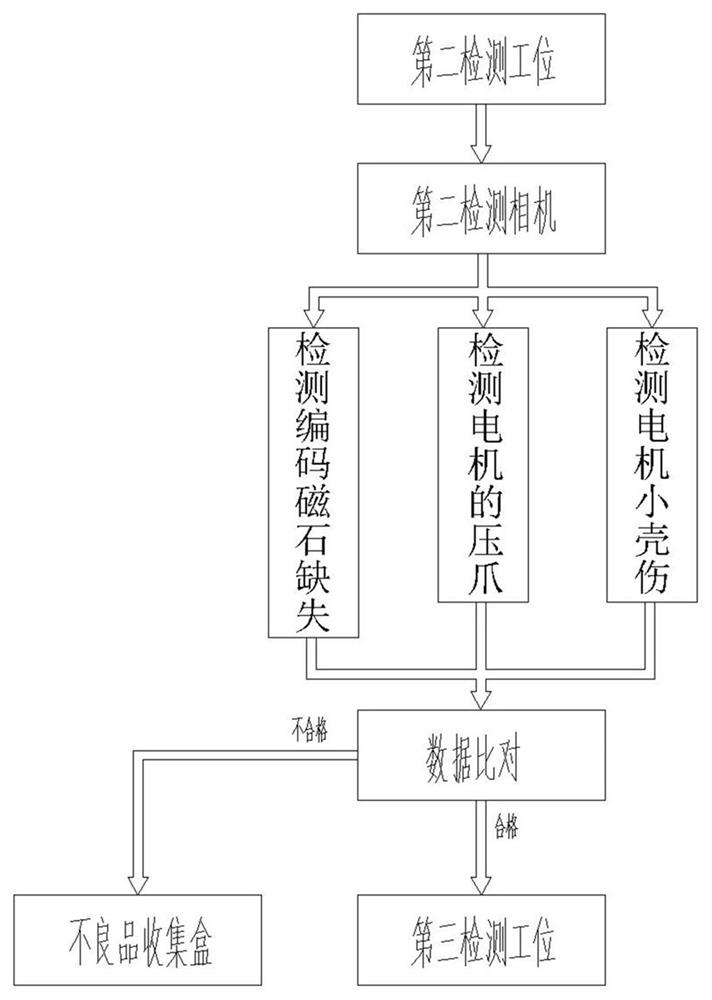

[0024] The present invention adopts four detection stations, and the motor is sent to the four detection stations sequentially through the transmission mechanism, for small shell damage, terminal deformation, reversed coded magnet, poor terminal height, and a failure of the pressing claw of the motor. Buckle the small shell, motor leak pressure claw, missing coding magnet, bad height of coding magnet, missing coding magnet, reversed label, missing or dirty QR code on label, dimension of QR code and label edge not within specification range, duplication Detection of labeling, wrong label placement, crooked labeling, missed labeling, handwriting on the large shell, screw hole damage, shaft damage, gear oxidation, missing tapping on the large shell, foreign objects in the screw hole, gear damage, etc., specifically The detection method is as follows:

[0025] A. The motor to be tested is transmitted to the conveying rail by vibrating the feeding tray, and the induction mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com