Insoluble particle detection assembly line

An assembly line and particle technology, applied in the direction of measuring devices, particle size analysis, particle and sedimentation analysis, etc., can solve problems such as inability to detect in batches, blockage, and unexpected situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

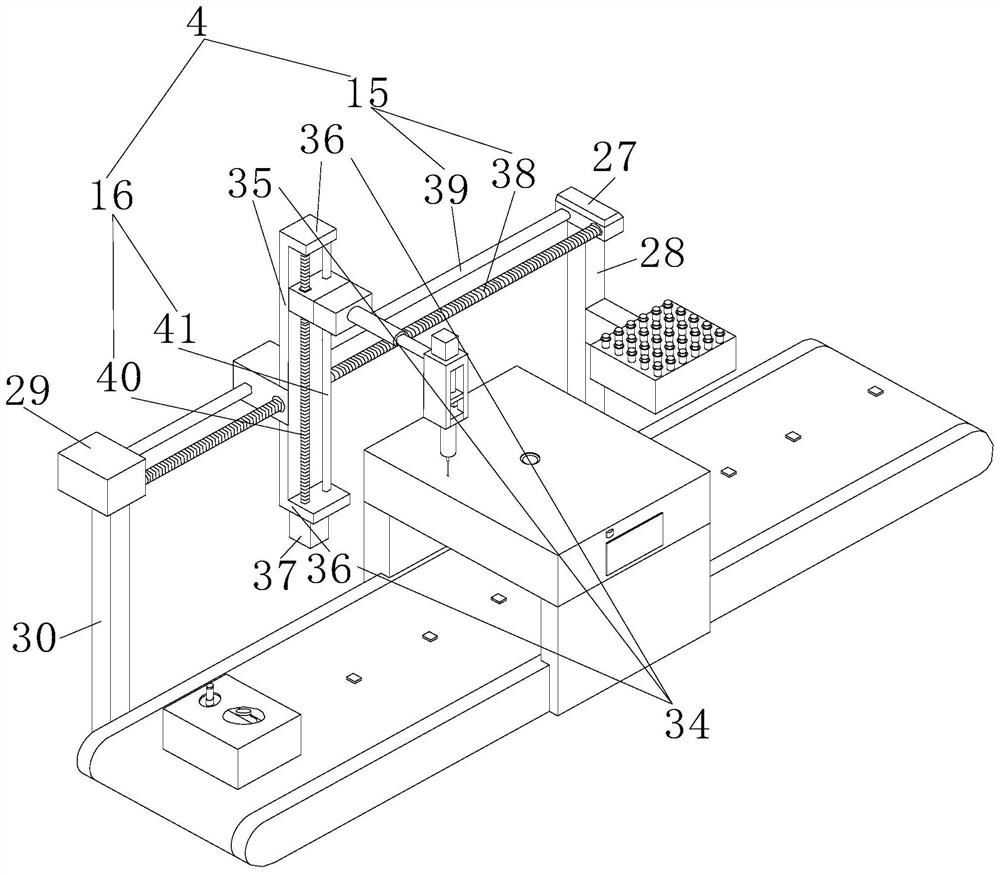

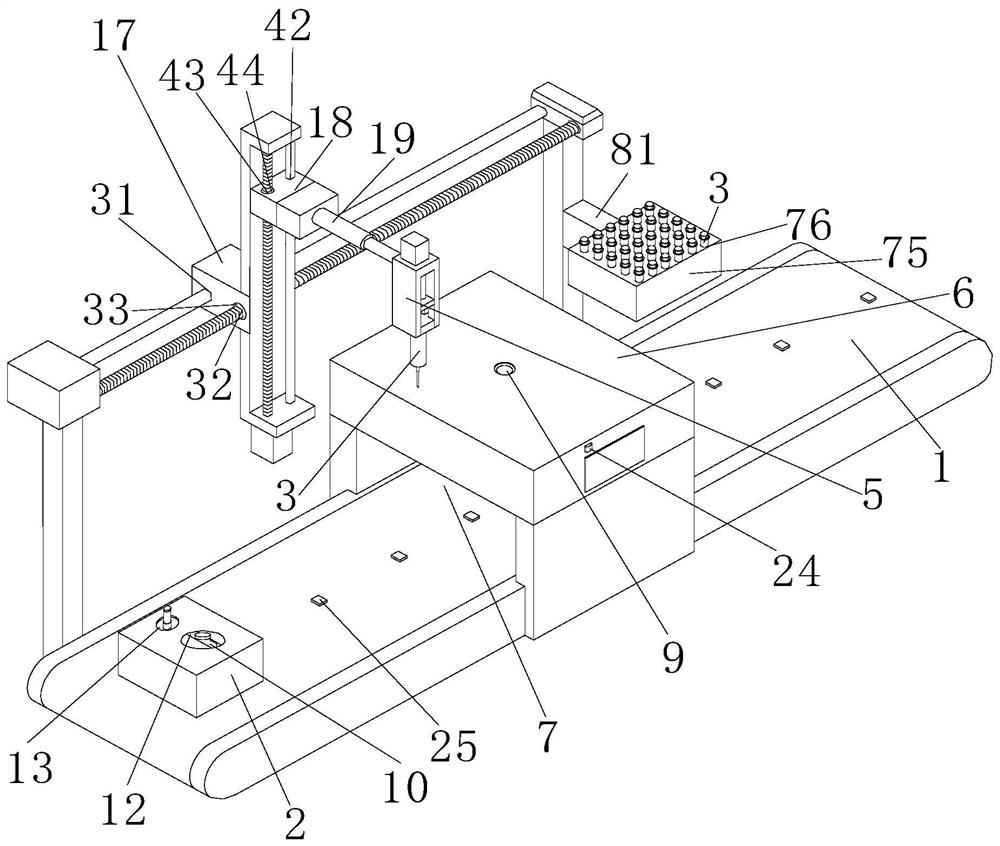

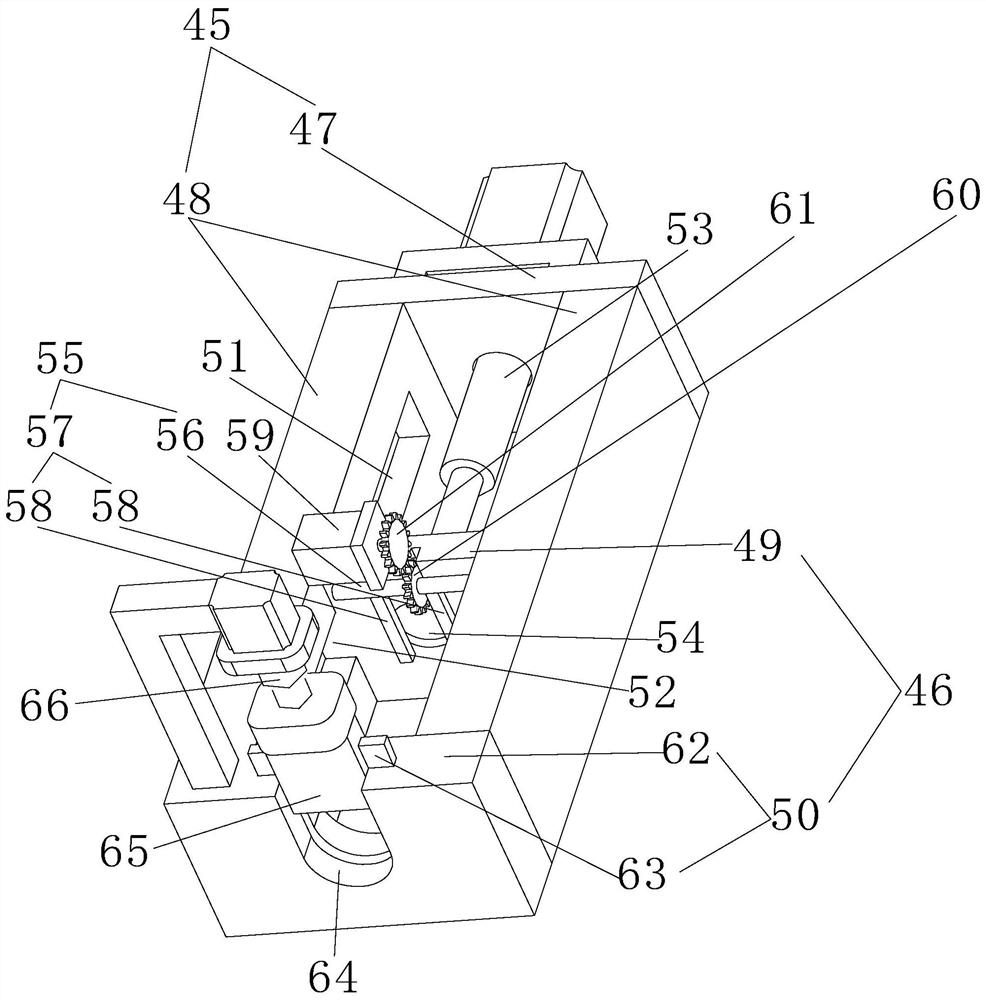

[0028] Such as Figure 1-Figure 8 As shown, the insoluble particle detection assembly line includes a conveyor belt 1, a feeding box 2, a syringe 3, a moving mechanism 4, a control device 5, and a photoresisting method detection device 6. The syringe of the syringe 3 is transparent, and the photoresisting method detection device 6 It is arranged above the conveyor belt 1, and there is a passageway 7 for the material box 2 to pass between the photoresistance method detection device 6 and the conveyor belt 1. The photoresistance method detection device 6 is internally provided with a sample channel 8, a processing device 20, a laser The transmitter 21 and the light receiving plate 22, the laser emitter 21 and the light receiving p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com