Dust falling and purifying device used in high-dust environment

A technology for purifying devices and dust, applied in spraying devices, chemical instruments and methods, using liquid separation agents, etc., can solve the problems of outdoor environmental pollution, troublesome maintenance, etc., achieve low cost, prolong the maintenance period, and ensure the effect of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

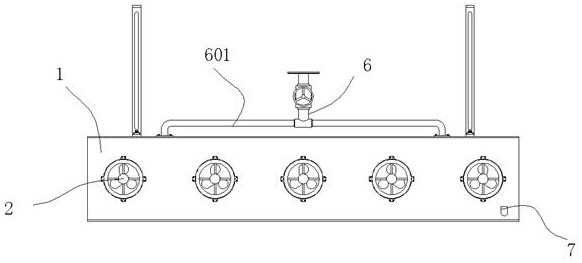

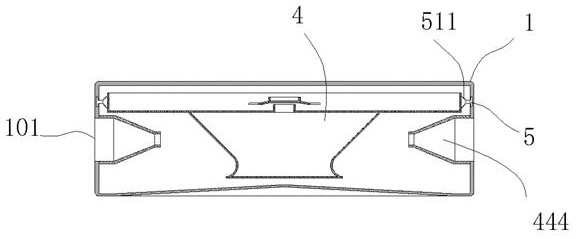

[0035]A dust reduction and purification device used in a high-dust environment, comprising a box body 1, the box body 1 adopts a hanging installation, and the hanging installation method can install the box body 1 according to the dust suspension height in the workshop. Maximum height to achieve better adsorption and filtration effect. Air inlet holes 101 are provided on the front and rear end faces of the box body 1 , and the diameter of the ventilation holes 101 is 16 cm. According to the size of the workshop, select the ventilation hole 101 with a reasonable aperture. At the front and rear end faces of the box body 1, an air intake fan 2 is installed corresponding to the air inlet hole 101. The air intake fan 2 adopts a common single-motor fan, and the power of each air intake fan 2 is 35W. A special-shaped opening 3 is arranged on the side of the box body 1, and the inner box body 4 fits through the special-shaped opening 3. After the inner box body 4 is inserted, it fits...

Embodiment 2

[0037] At the bottom of the upper box 402, a plurality of ventilation holes 9 are arranged on the outside of the lower box 401. The aperture of the ventilation holes 9 is larger than the aperture of the dripping hole 403. In the ventilation holes 9 An inner ring 8 is built in, and the inner wall of the inner ring 8 is annularly provided with a plurality of spikes 801 , and a V-shaped flow channel 802 is formed between two adjacent spikes 801 .

[0038] In the above-mentioned technical solution, we use a vent hole 9 with a relatively large aperture, which can increase the exhaust efficiency. At the same time, an inner ring 8 is built in. The inner ring 8 has a plurality of spikes 801. After water enters the vent hole 9, it passes through A plurality of spikes 801 divide the flow to form a water curtain, and the air needs to pass through the water curtain before entering the ventilation hole 9 . At the same time, the blocking of the drip hole 403 caused by the excessive water fl...

Embodiment 3

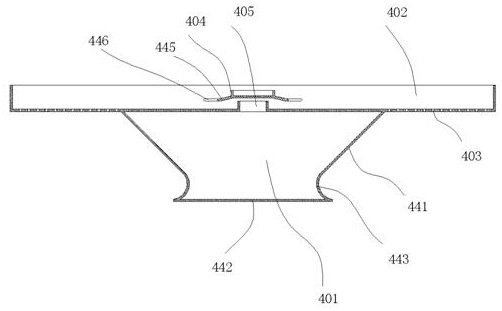

[0040] The lower box 401 has an inclined surface 441 corresponding to the air inlet hole 101, the bottom of the lower box 401 is provided with a bottom surface 442, and the transition between the inclined surface 441 and the bottom surface 442 is arc-shaped Surface 443 ; a tapered air inlet nozzle 444 is provided inside the box body 1 , and the diameter of the end of the air inlet nozzle 444 close to the inclined surface 441 gradually decreases.

[0041] In the above-mentioned technical solution, the conical air inlet nozzle 444 plays the role of gathering air and increasing the air flow rate. After entering, the accelerated air touches the inclined surface 441 and most of it is scattered downwards, and then moves upwards. Finally, it passes through the drip hole 403. In this way, the water in the drip hole 403 will generate water mist when it contacts the water deposited below, and the air moving downward can contact this part of the water mist to increase the purification of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com