Silent constant-temperature heating method and system and container using system

A constant temperature heating and silent technology, applied in the field of liquid heating, can solve problems such as implosion, health impact, stainless steel oxidation, etc., and achieve the effect of light weight, small space occupation and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

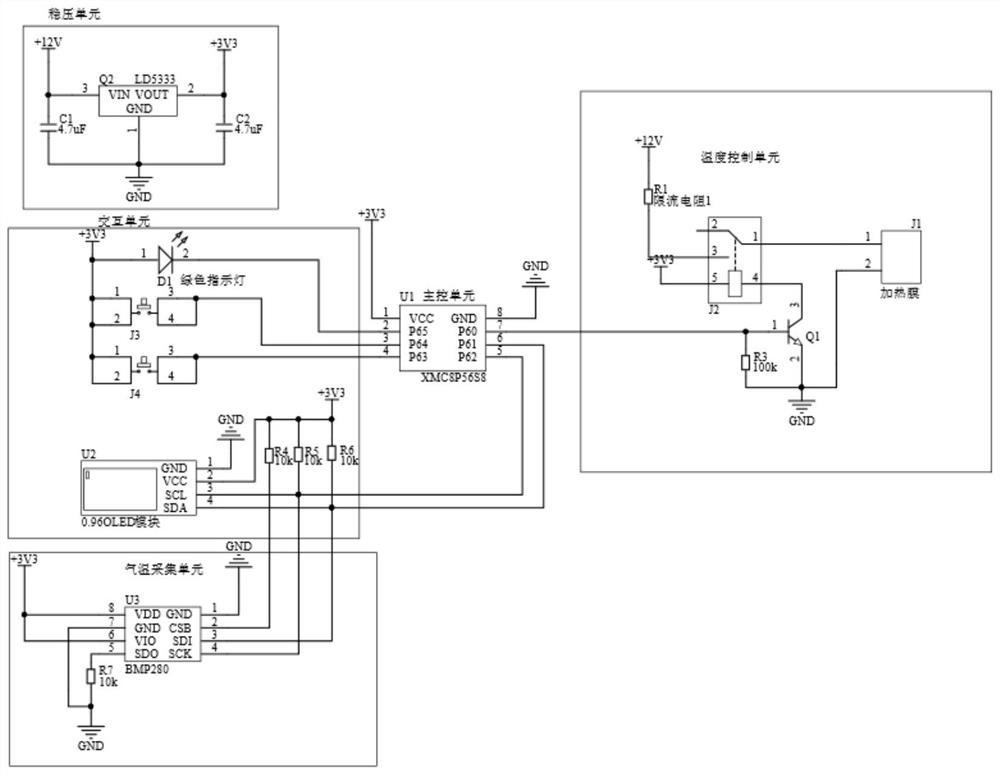

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] see figure 1 , the present invention aims at the problem of noise generated when the liquid boils, and provides a quiet constant temperature heating method, which includes the following steps.

[0027] Step 1: Obtain the target temperature and air pressure. The main control unit acquires the temperature of the liquid to be heated and the current ambient air pressure through the air temperature acquisition unit at regular intervals, and obtains the boiling point of the liquid under the current air pressure according to the acquired air pressure. Specific steps are as follows:

[0028] Step 1.1: Read the temperature and air pressure, and communicate with the air pressure sensor and temperature sensor through the I2C protocol to obtain the current atmospheric pressure value P and temperature value T.

[0029] Step 1.2: After obtaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com