Five-point positioning-based shaft-sticking type motor installation test device

A technology of test device and motor mounting frame, which is applied in the direction of motor generator test, measuring device, measuring device casing, etc., can solve the problems of no bearing, poor versatility, high cost, etc., and achieve the effect of fast adjustment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

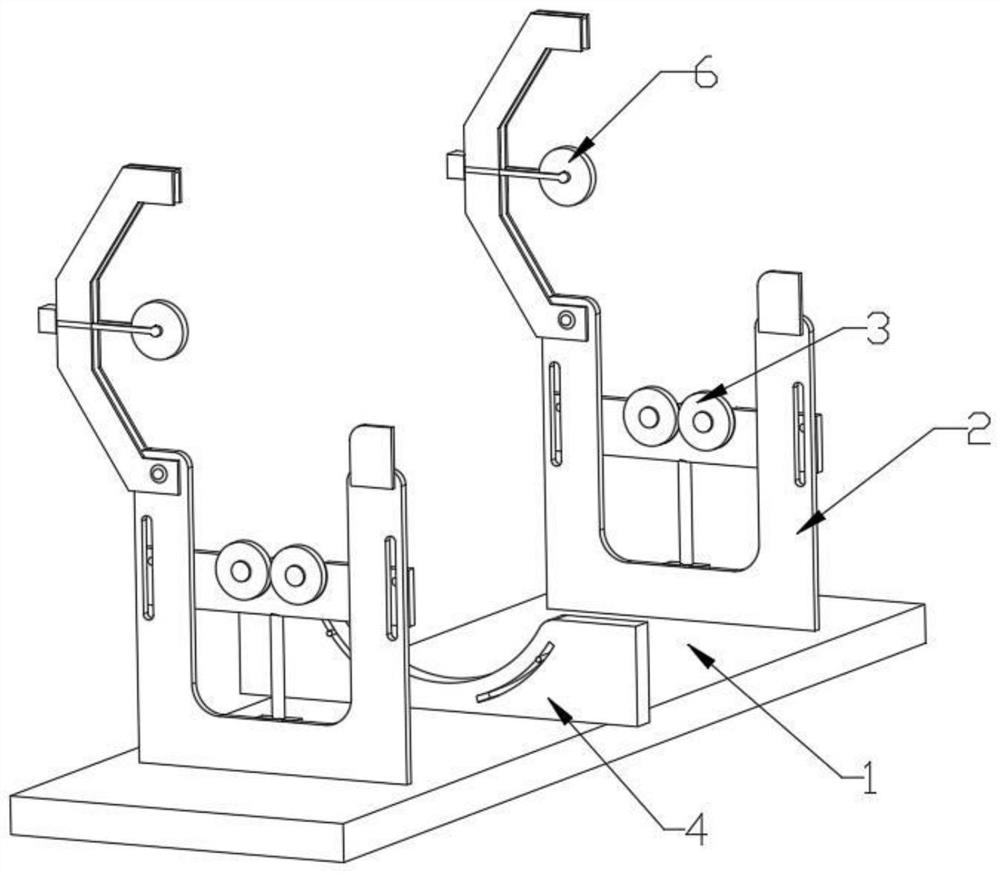

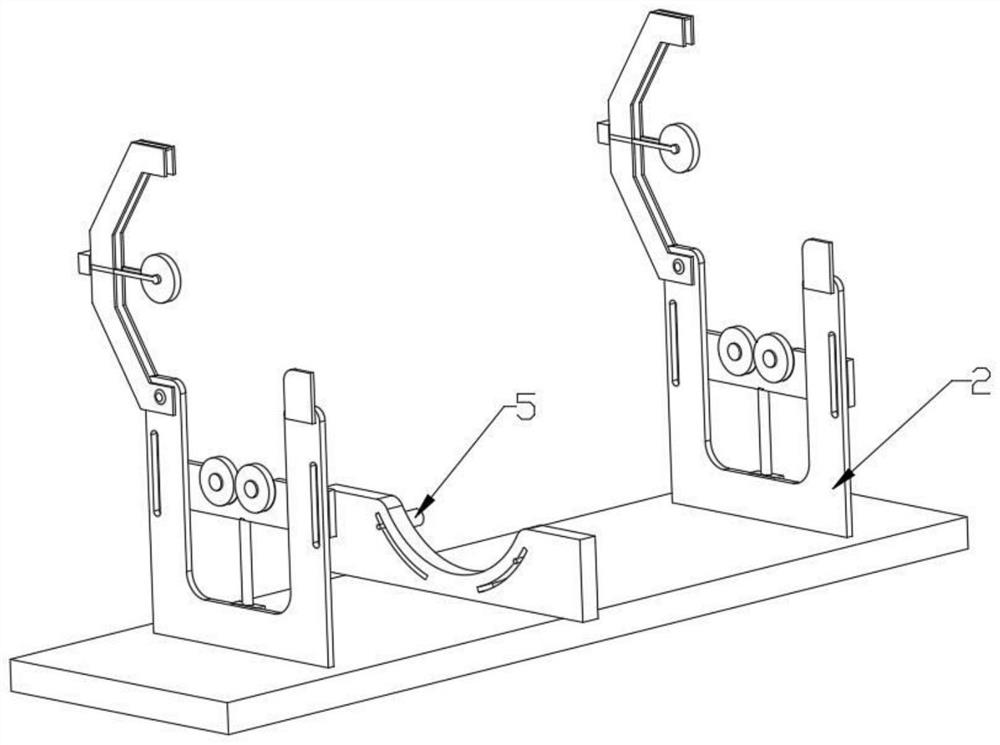

[0025] Such as Figure 1-2 As shown, the shaft-holding type motor installation test device based on five-point positioning includes a base plate 1, and the base plate 1 is provided with a slide rail (not shown) that is flush with the base plate 1, and the slide rail ( not shown in the figure) are provided with two movable supports 2,

[0026] The support 2 is provided with a horizontal support that can move up and down, the two ends of the horizontal support are connected with the support through guide rails, and the middle part of the horizontal support is connected with the first motor through the first screw rod;

[0027] Two transverse posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com