Ship lock reverse arc-shaped valve top water stop installation structure and transformation construction technology

A technology of installation structure and top stop, which is used in ship locks, ship lifting devices, climate change adaptation and other directions, can solve problems such as affecting normal operation, affecting the normal navigation of ship locks, and hidden safety hazards of anti-arc doors and opening and closing systems. Convenience and fixing reliability, reducing the repair work of failed screw holes, and improving the efficiency of replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

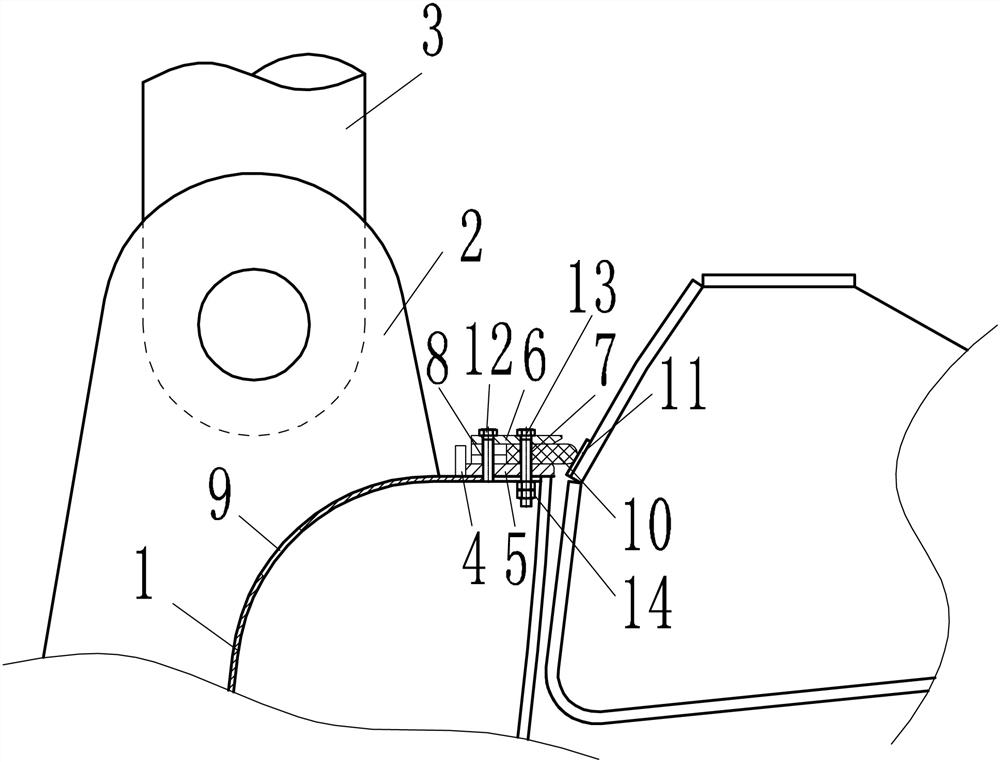

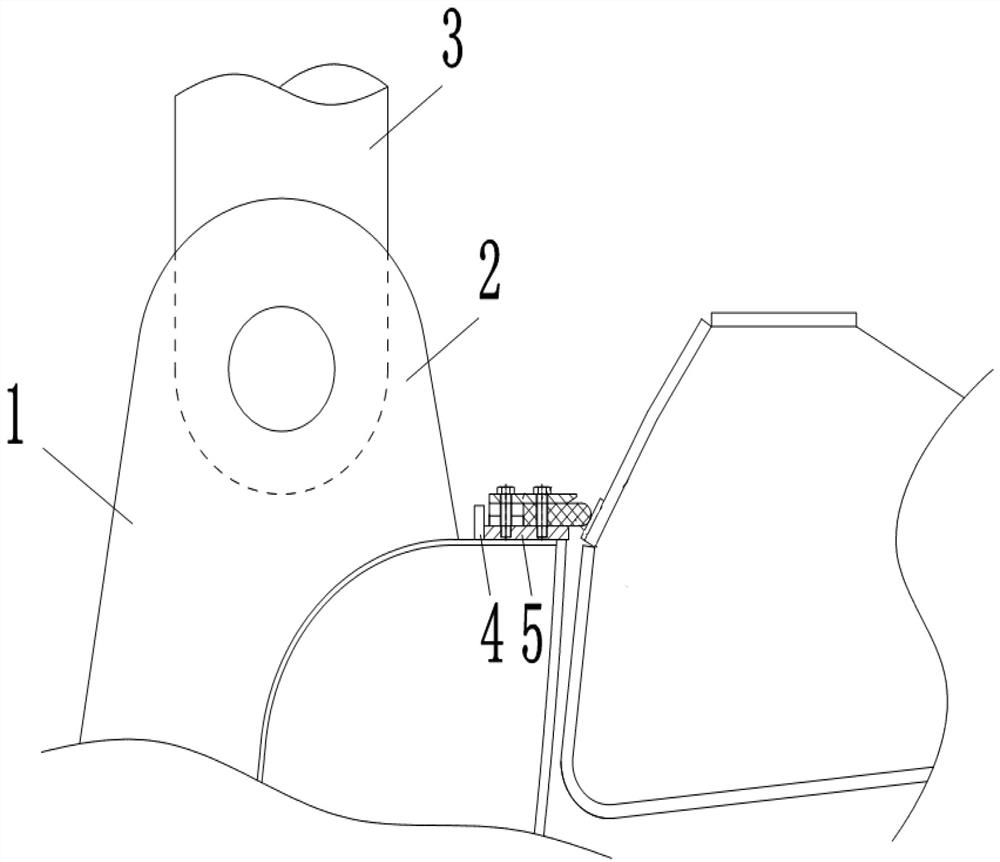

[0033] see figure 1 , a ship lock reverse arc valve top water stop installation structure, which includes a reverse arc door 1, the door body hanging ear 2 is fixedly installed on the anti arc door 1, and a suspender rod 3 is hinged on the door body lifting ear 2, The top edge of the anti-arc door 1 is provided with a water-stop seat plate 5, and the front row of the water-stop seat plate 5 and the anti-arc door 1 is processed with a through front fixed screw hole 7; the water-stop seat plate 5 and the anti-arc door 1 The rear row is processed with rear fixing screw holes 8; the top of the water stop plate 5 is fixedly installed with the top water stop 10 through the top water stop pressure plate 6; the end of the top water stop 10 is matched with the lintel water stop plate 11; A plurality of process holes 9 are processed on the deflector plate on the water-facing surface of the anti-arc door 1 . By adopting the top water stop installation structure of the above structure, t...

Embodiment 2

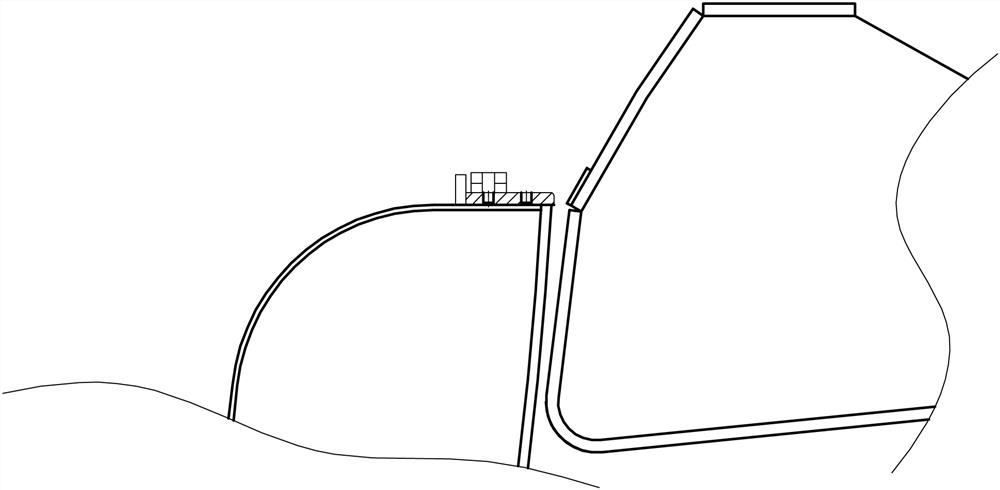

[0042] see Figure 3-8 , the reconstruction construction process of the water-stop installation structure on the reverse arc valve top of the ship lock, including the following steps:

[0043] Step 1: Remove the original top water stop 10 of the anti-arc door 1 and its pressure plate fastening bolts;

[0044] Step 2: Use a magnetic electric drill to modify the threads of the blind holes in the front row of the water-stop plate 5, and drill them into perforations to form the front fixed screw holes 7; The wire is a through-hole thread, and then forms the rear row of fixing screw holes 8;

[0045] Step 3: Add a plurality of process holes 9 on the deflector plate on the water-facing surface of the anti-arc door 1, so that the construction personnel's arms can reach into the nuts 14 for installing and fastening the front row bolts 13 of the top water stop;

[0046] Step 4: Adjust the compression of the top water stop 10 and the lintel water stop plate 11 to the set value on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com