Paint spraying device for round block hole type graphite heat exchanger

A graphite heat exchanger and hole-type technology, applied in the direction of spraying devices, etc., can solve the problems of easily damaged workpiece surface, cumbersome clamping operation, inconvenient use, etc., and achieve the effect of avoiding workpiece damage, saving manpower and material resources, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

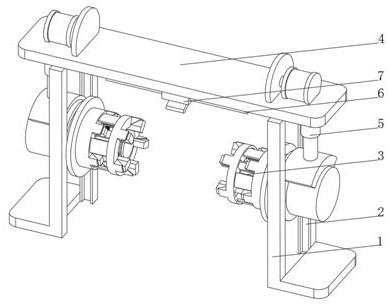

[0038] see Figure 1-3, the present invention provides a technical solution: a paint spraying device for a round hole graphite heat exchanger, specifically comprising:

[0039] The fixed bracket 1 is provided with a slideway 2 on both sides of the fixed bracket 1, and the inner wall of the slideway 2 is slidably connected with a positioning device 3, and one end of the positioning device 3 extends to the outside of the fixed bracket 1.

[0040] The fixed top plate 4, the bottom of both ends of the fixed top plate 4 are fixedly connected with the top of the fixed support 1, and the part of the fixed top plate 4 located at the inner side of the fixed support 1 is fixedly connected with a hydraulic lifting rod 5.

[0041] The fixed slideway 6 is arranged on the fixed top plate 4 and fixedly connected with the fixed top plate 4 , and the bottom of the fixed slideway 6 is slidably connected with a spraying device 7 .

[0042] Positioning device 3 includes:

[0043] The positionin...

Embodiment 2

[0051] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the driving device 32 includes a hydraulic push rod 321, the outer side of the hydraulic push rod 321 is provided with an annular limit plate 322, and the top of one end of the hydraulic push rod 321 is fixedly connected with an arc Lifting plate 323, one end of the hydraulic push rod 321 away from the arc-shaped lifting plate 323 is fixedly connected with a rotating seat 324, and one side of the rotating seat 324 is fixedly connected with a driven gear 325, and a driving gear 326 is arranged above the driven gear 325, and the driving gear One side of 326 is fixedly connected with driving motor 327 through a rotating shaft, the top of arc-shaped lifting plate 323 is fixedly connected with the bottom of hydraulic lifting rod 5, the side of driven gear 325 away from rotating seat 324 is fixedly connected with positioning plate 31, and the ring-shaped limiting plate 322 Both ...

Embodiment 3

[0054] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the spraying device 7 includes a sliding seat 71, the bottom of the sliding seat 71 is fixedly connected with the outer ring of the rotating bearing 72, and the inner ring of the rotating bearing 72 is fixedly connected There are arc-shaped spray nozzles 73, the top of the sliding seat 71 is connected to the fixed slideway 6 and slides on the fixed slideway 6, and the discharge nozzles at the bottom of the arc-shaped spray nozzle 73 are arranged in multiple groups and evenly distributed, and a spraying device 7 is provided. 7 The bottom is provided with an arc-shaped nozzle 73, which can adapt to the arc-shaped surface of the workpiece through the arc-shaped nozzle 73, avoiding the color difference caused by the different distances between the positions of the workpiece and the nozzle, and the arc-shaped nozzle 73 is on the sliding seat 71 through the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com