Guiding hollow screw with implantable filler

A technology of hollow screws and fillers, applied in the direction of internal bone synthesis, fixers, fastening devices, etc., can solve the problems of affecting fracture recovery, affecting internal fixation operations, and not being able to set fillers well, so as to promote closure and Recovery, avoiding the effect of poor fracture recovery or deformity recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides a hollow screw with guiding implantable filler. The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings for a better understanding of the present invention, but does not limit the scope of the present invention.

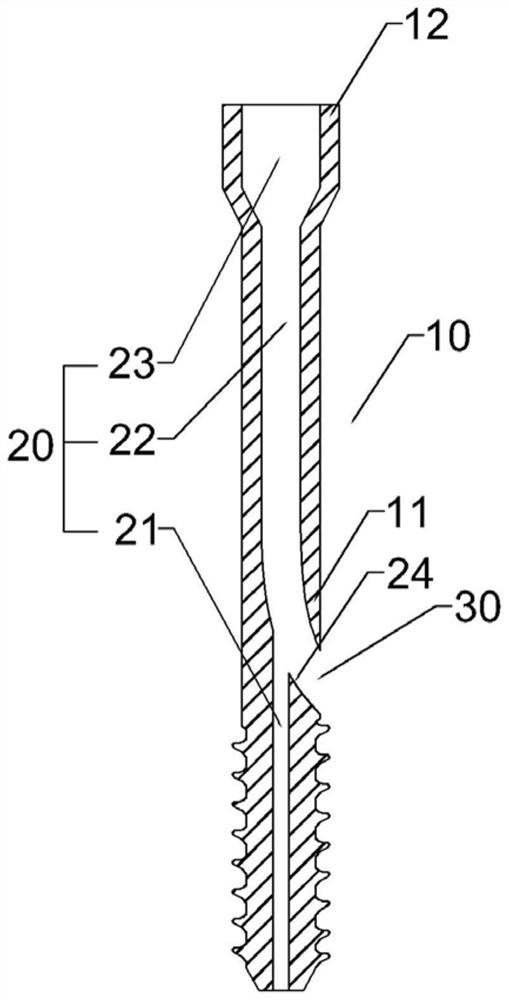

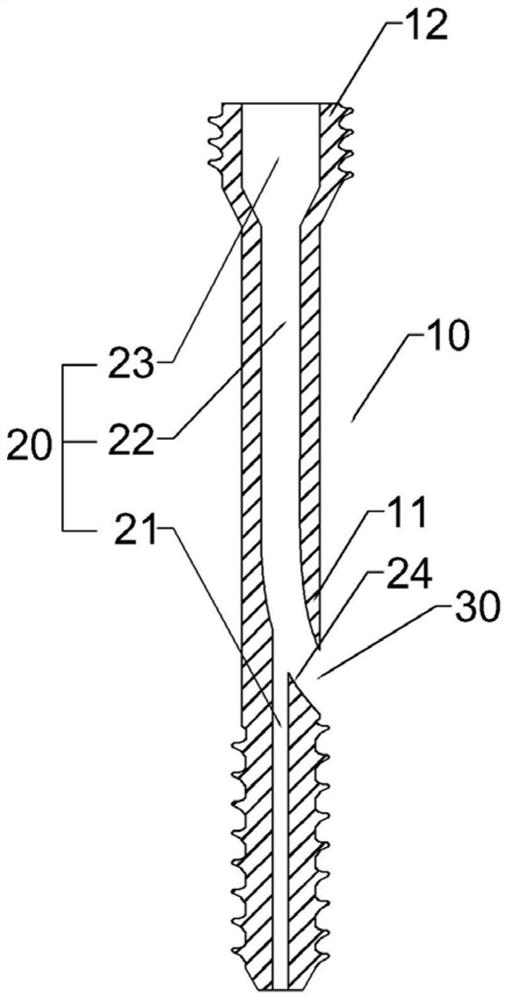

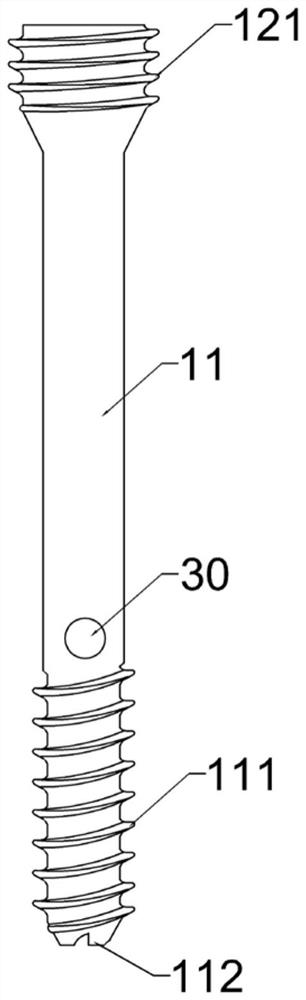

[0031] like Figure 1~3 As shown, the present invention provides a hollow screw with guiding implantable filler, which includes a screw body 10 , and a guide hole 20 is arranged in the screw body 10 coaxially with the screw body 10 . Like other hollow screws in the prior art, the guide hole 20 is used to pass through the guide pin, and the guide pin is used to position and implant the screw body 10 for implantation of the hollow screw and internal fixation of the fracture.

[0032] The screw body 10 provided by the present invention includes two parts: a nail shank 11 and a nail tail 12. The nail tail 12 is connected to the tail end of the nail shank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com