Gear adjusting circuit and method of electric tool

A technology for electric tools and gear adjustment, which is applied in the direction of AC motor control, electrical components, control systems, etc., can solve the problems that the gears of electric tools cannot fully match the user's usage habits intelligently, and cannot meet the user's habitual needs. Customary requirements, intelligent gear adjustment, and the effect of reducing gear switching operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

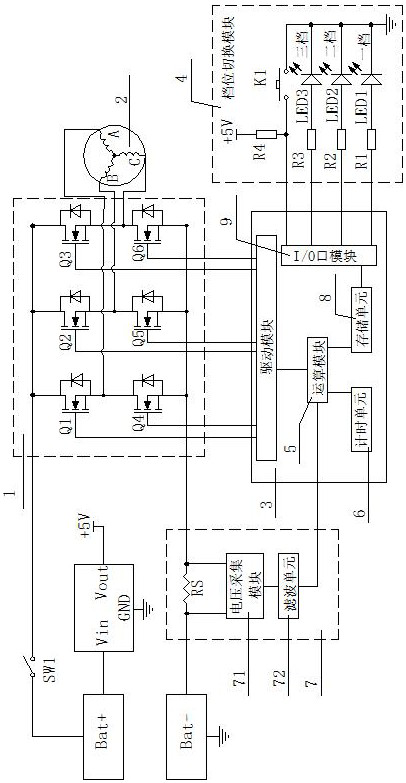

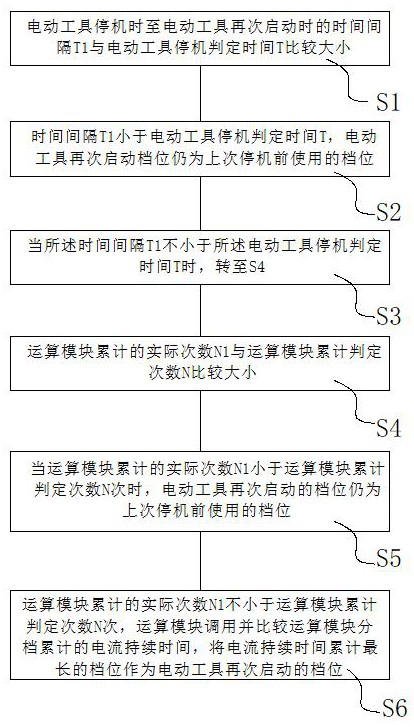

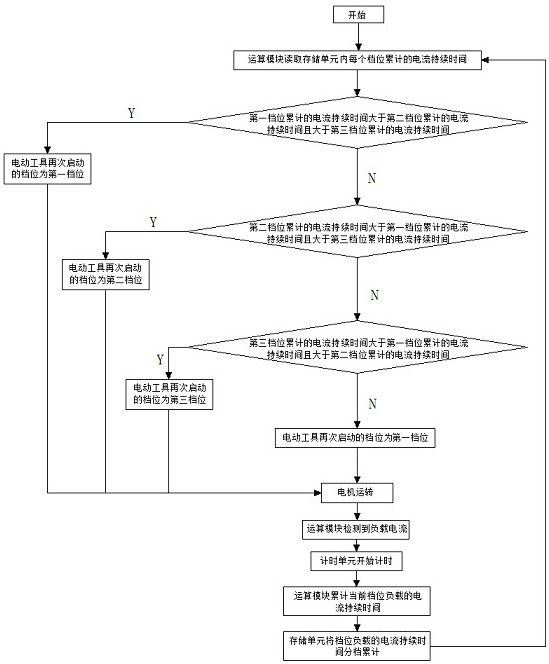

[0031] Such as figure 1 The gear adjustment circuit of an electric tool as shown includes positive and negative terminals of the circuit, the positive terminal of the circuit is electrically connected to the motor 2 through the inverter 1, and the inverter 1 is electrically connected to the controller 3, so The controller 3 is electrically connected to the gear switching module 4, the controller 3 includes an operation module 5 and a timing unit 6, the inverter 3 is electrically connected to a current acquisition module 7, and the current acquisition module 7 samples the The current when the electric tool is running, the operation module 5 is electrically connected to the current acquisition module 7, and detects the current when the electric tool is loaded; the timing unit 6 is electrically connected to the operation module 5, and counts the electric current The current duration of the tool when each gear is loaded; the operation module 5 accumulates the corresponding current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com