Vibration compaction device and vibration compaction method for backfill area in building construction

A technology of vibratory compaction and building construction, which is applied in the direction of filling, construction, and basic structure engineering, etc., and can solve problems such as uneven distribution of backfill soil and different effects of vibration compaction, so as to achieve improved vibration compaction effect and better return of backfill soil. Tightening, avoiding the effect of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

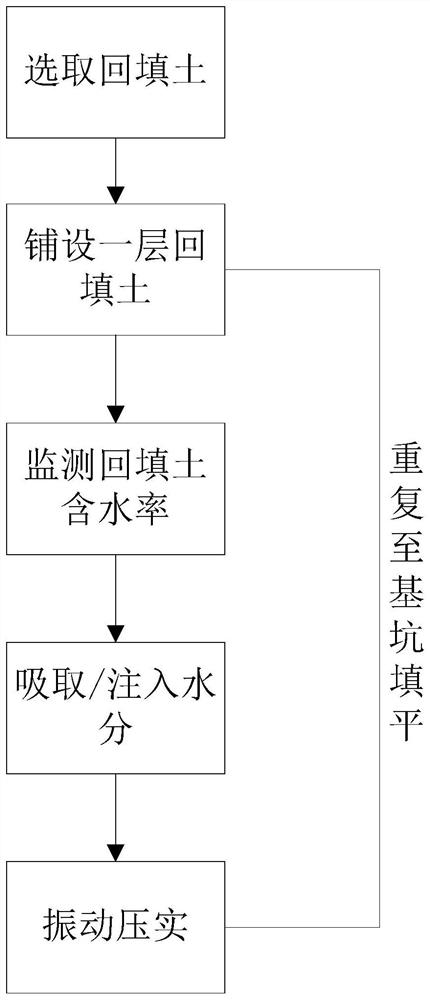

[0047] Such as figure 1 As shown, the vibratory compaction method in the backfill area in building construction includes the following steps:

[0048] Select the backfill soil and lay the backfill soil layer by layer into the foundation pit;

[0049] Every time a layer of backfill is laid, vibratory compaction is carried out once;

[0050] Before vibrating and compacting the backfill, the moisture content of the backfill is monitored in real time;

[0051] Vibrating and compacting the backfill, sucking out the moisture in the backfill through infiltration at a position with a high moisture content of the backfill, and injecting water into the backfill through direct water injection at a position with a low moisture content of the backfill;

[0052] A geogrid is placed under each layer of backfill soil.

[0053] The thickness of each layer of backfill soil is 200-300 mm.

[0054] In the practical application of this embodiment, the backfill soil is screened first, so that t...

Embodiment 2

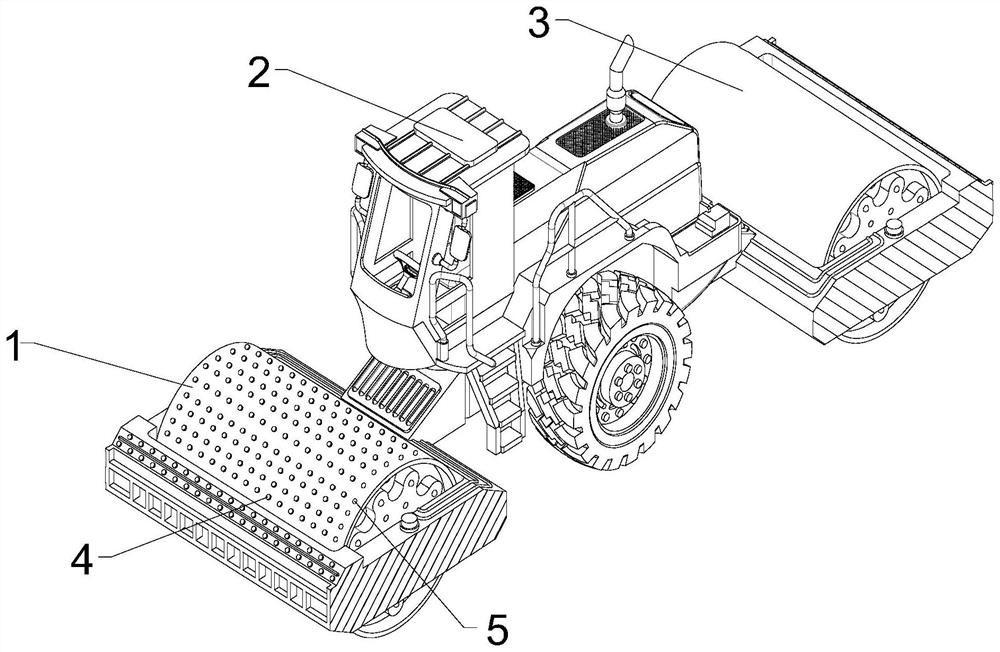

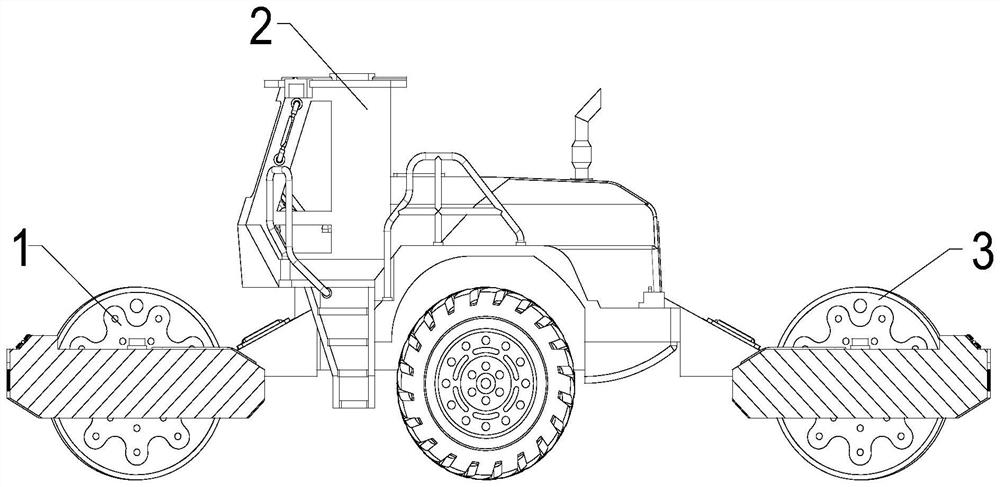

[0065] Such as Figure 1-7 As shown, on the basis of applying the method of Example 1, this embodiment relates to a vibratory compaction device for a vibratory compaction method in a backfill area during construction, including a front compaction roller 1 and a power vehicle body 2. The compaction roller 1 is provided with a water content balance mechanism 4 , which is fixed with the front compaction roller 1 and extends from the front compaction roller 1 to the outer surface of the front compaction roller 1 .

[0066] In this embodiment, the determination of the water content of the backfill is determined by the conductivity of the backfill, and the measuring electrode 5 needs to be arranged on the front compacting roller 1 in addition to being arranged on the geogrid. The embodiment configures the measuring electrode 5 at the edge position of the front compaction roller 1, and the measuring electrodes 5 are arranged on both sides of the edge, so that the average value of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com