Transfer system and method for ships or large components

A technology for large-scale components and ships, applied in the field of transport systems for ships or large-scale components, can solve problems such as poor reliability and stability, high cost, etc., and achieve the effects of high reliability and stability, high degree of automation, and high utilization rate of the wharf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] In order to better understand the above-mentioned technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

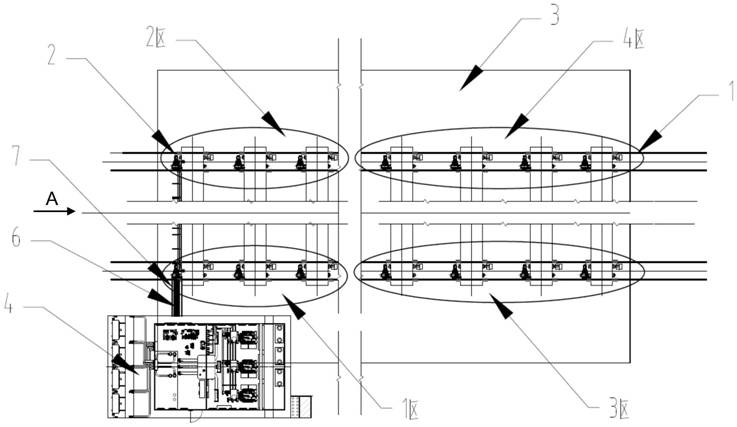

[0099] combine Figure 1 to Figure 12 As shown, a kind of transshipment system for ships or large components provided by the present invention includes:

[0100] Walking guide rail 1, paved on the ground at the site;

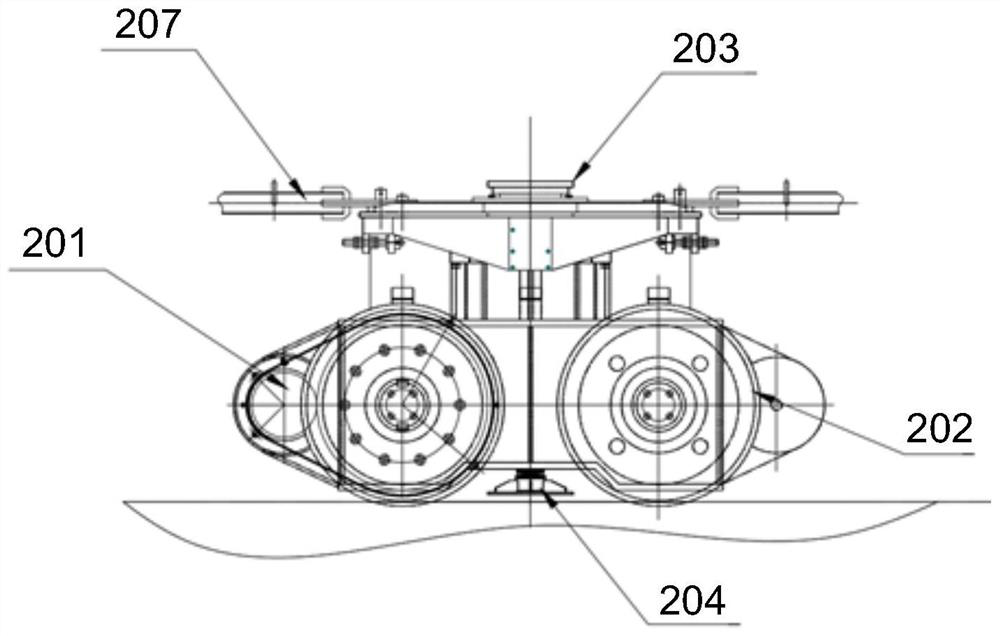

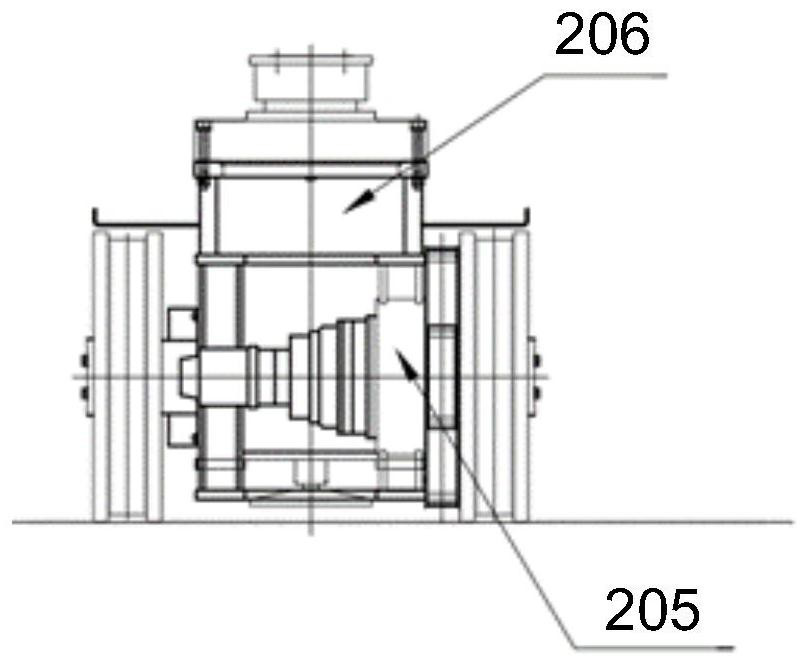

[0101] Ship moving trolley 2, which has multiple sets, is set on the walking guide rail 1, and is used to lift and move the ship or large component 3;

[0102] The power unit car 4 is connected with the ship moving trolley 2 to provide power for the ship moving trolley 2;

[0103] The operation console 5 controls the actions of the ship moving trolley 2 and the power unit vehicle 4 through the main control PLC.

[0104] The ship shifting trolley 2 is designed in a standard modular manner and can be interchanged arbitrarily. Tonn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com