Auxiliary device for detecting hardness of slender shaft body and use method of auxiliary device

An auxiliary device and a slender shaft technology, which is applied in the direction of measuring devices, testing material hardness, and preparation of test samples, can solve the problems of low hardness detection accuracy and achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

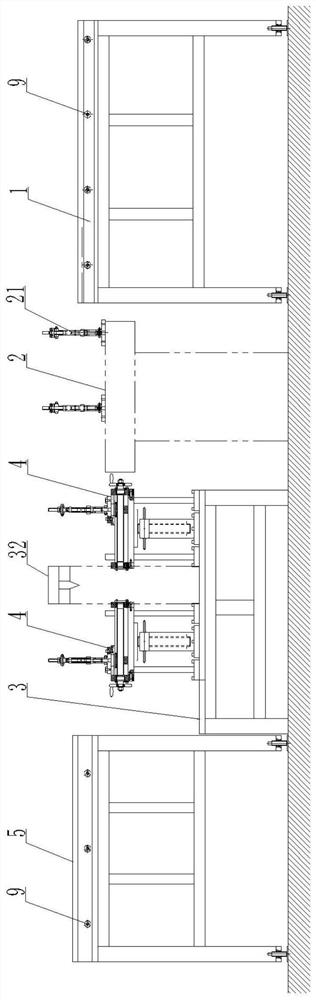

[0030] Such as Figures 1 to 9 As shown, a slender shaft body hardness detection auxiliary device includes a raw material storage rack assembly 1, a milling machine base assembly 2, a hardness machine storage rack assembly 3, an adjustable seat assembly 4, and a finished product storage rack assembly 5, The raw material storage rack assembly 1 is connected to one end of the milling machine base assembly 2, the other end of the milling machine base assembly 2 is connected to one end of the hardness machine storage rack assembly 3, and the hardness machine storage rack assembly 3 is provided with an adjustable base assembly 4 , the other end of the hardness machine storage rack assembly 3 is connected with the finished product storage rack assembly 5.

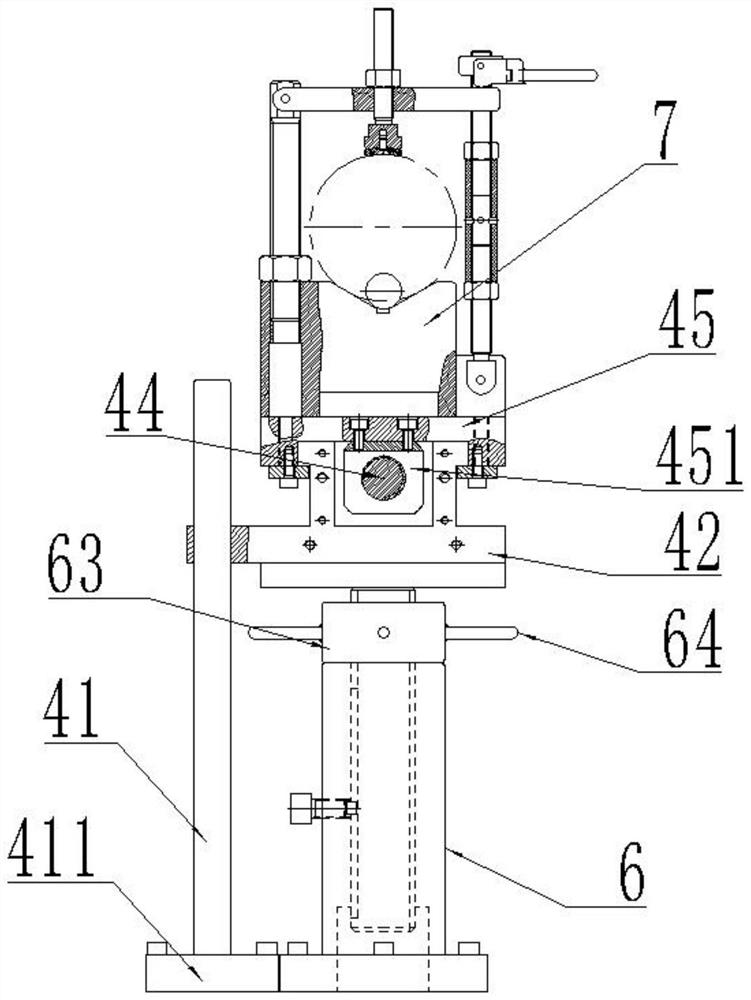

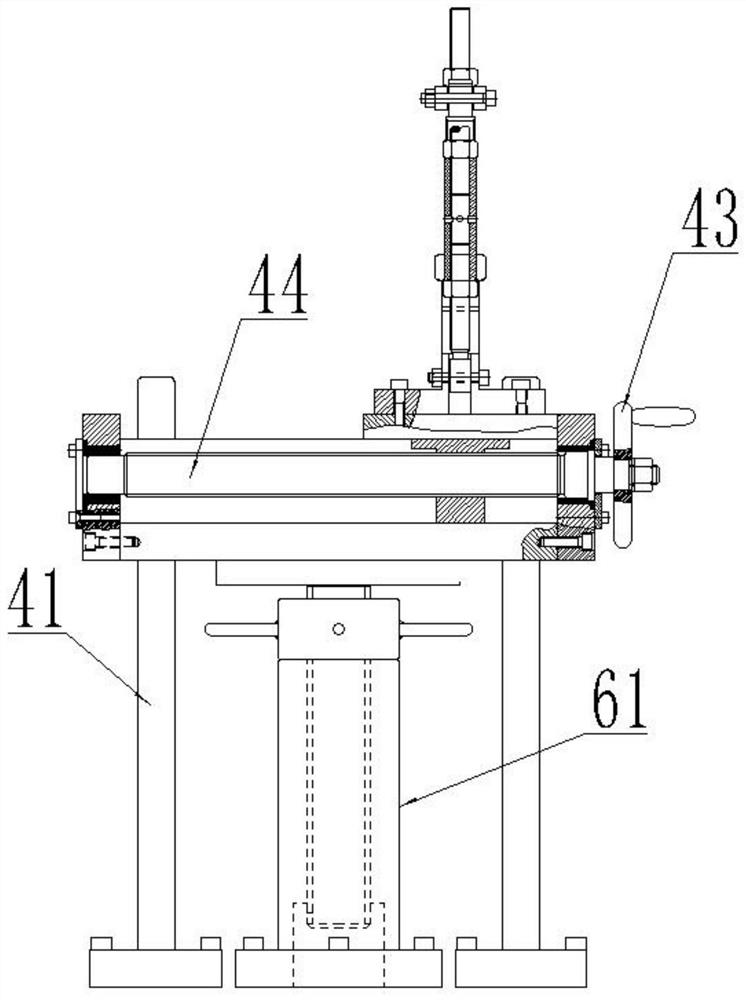

[0031] The adjustable seat assembly 4 includes a lifting assembly 6, a guide post 41, a U-shaped seat 42, a rotating handle 43, a screw A44, a moving seat 45, and a V-shaped seat assembly 46. The lifting assembly 6 and the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com