Relay detection device capable of improving detection efficiency

A detection device and detection efficiency technology, which is applied in the direction of transportation and packaging, circuit breaker testing, conveyor objects, etc., can solve the problems of slow detection speed of relays, and achieve the goals of avoiding slow detection speed, improving detection efficiency, and improving detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

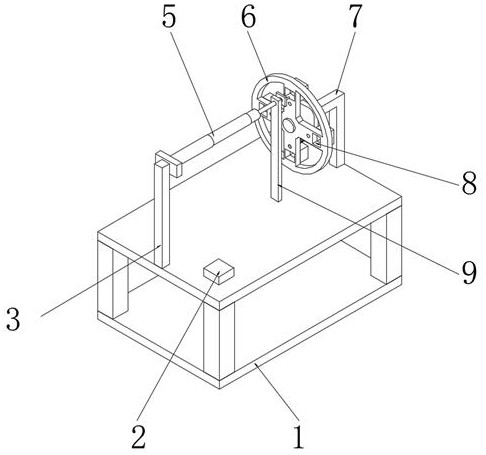

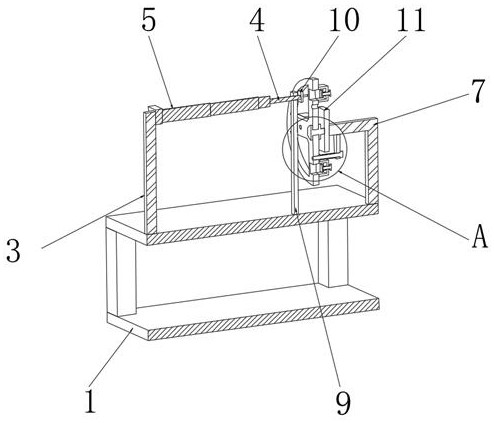

[0020] see Figure 1-3 , a relay detection device capable of improving detection efficiency, comprising a workbench 1, an L-shaped bracket 7 is fixedly installed on one end of the upper surface of the workbench 1, and a mounting plate 11 is fixedly mounted on the top of the L-shaped bracket 7, and the mounting plate 11 is far away from L A rotating shaft 21 is fixedly installed on one side of the type bracket 7, and a periodic feeding assembly is arranged on the outside of the rotating shaft 21. The periodic feeding assembly is used to place the relay and move the relay to the detection position. The upper surface of the workbench 1 is far away from L One end of the type bracket 7 is fixedly installed with a column 3, and the top of the column 3 is fixedly installed with a detection component, which is used for detecting the relay.

[0021] In a specific embodiment of the present invention, through the periodic feeding assembly, the feeding of multiple relays can be completed ...

Embodiment 2

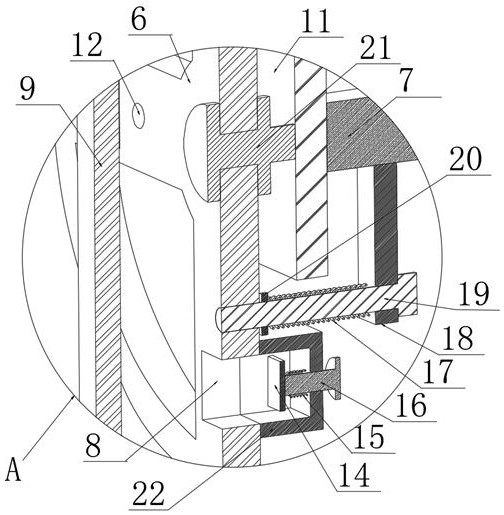

[0023] This embodiment is an improvement made on Embodiment 1. For details, please refer to Figure 1-3 , the periodic feeding assembly includes a turntable 6, the turntable 6 is movably socketed on the outside of the rotating shaft 21, one side of the turntable 6 is provided with a number of through grooves 8, and one side of the turntable 6 is fixed at the corresponding position of each through groove 8 An anti-off cover 22 is installed, and one side of the rotating disk 6 is provided with a locking hole 12 at the corresponding position of each through groove 8. The lower surface of the L-shaped support 7 is provided with a locking mechanism, and the locking mechanism is used to limit the rotating disk 6. Position, several through grooves 8 and several locking holes 12 are all arranged on one side of the turntable 6 around the rotating shaft 21 as the axis.

[0024] In this embodiment: several relays are respectively placed inside the through groove 8, and the turntable 6 ca...

Embodiment 3

[0026] This embodiment is an improvement made on Embodiment 1. For details, please refer to Figure 1-3 , the detection component includes an electric push rod 5, the electric push rod 5 is fixedly installed on the side of the column 3 facing the turntable 6, and the end of the electric push rod 5 away from the column 3 is fixedly installed with a limit column 4, and the limit column 4 is far away from the electric push rod One end of 5 is fixedly installed with connector plate 10, and one side of connector plate 10 is provided with several contact test columns, and the upper surface of workbench 1 is fixedly installed with digital display meter 2, and digital display meter 2 is electrically connected with contact test column.

[0027] In this embodiment: the electric push rod 5 is elongated, so that the electric push rod 5 pushes the limit post 4 and the joint plate 10 to move toward the turntable 6, so that several contact test posts on the joint plate 10 and the relay on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com