Gas-assisted flash optical lens injection mold

A technology for optical lenses and injection molds, which is applied in the direction of optical components, household appliances, and other household appliances, can solve problems such as impact, and achieve the effect of reducing the difficulty of grinding and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

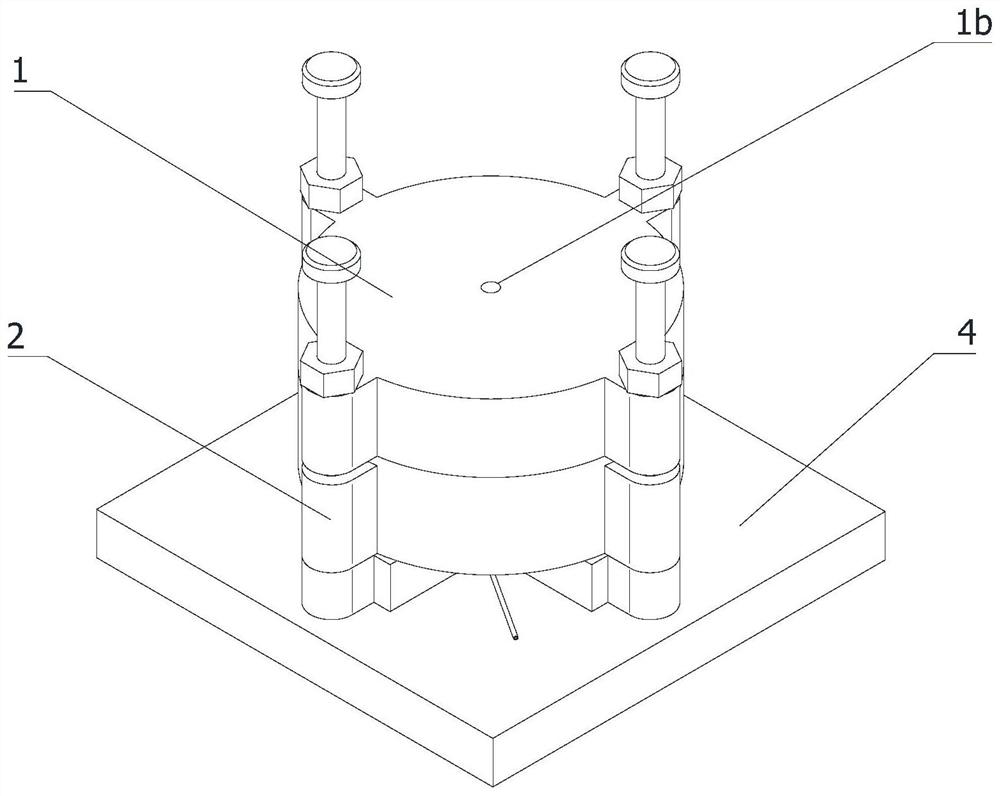

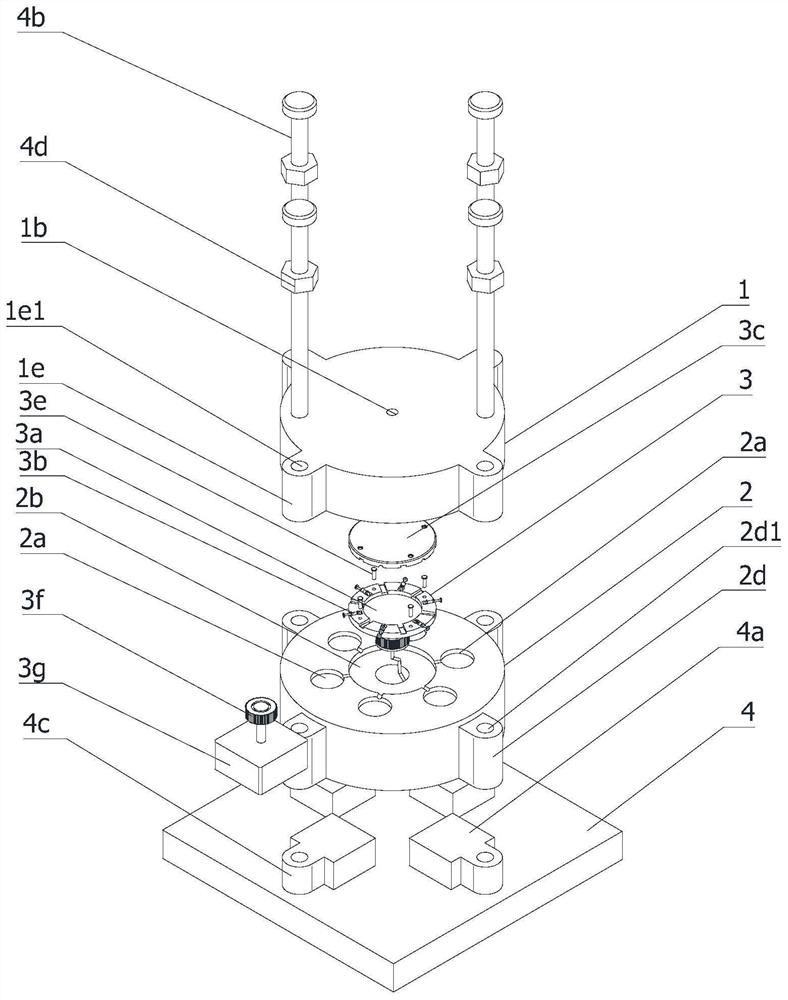

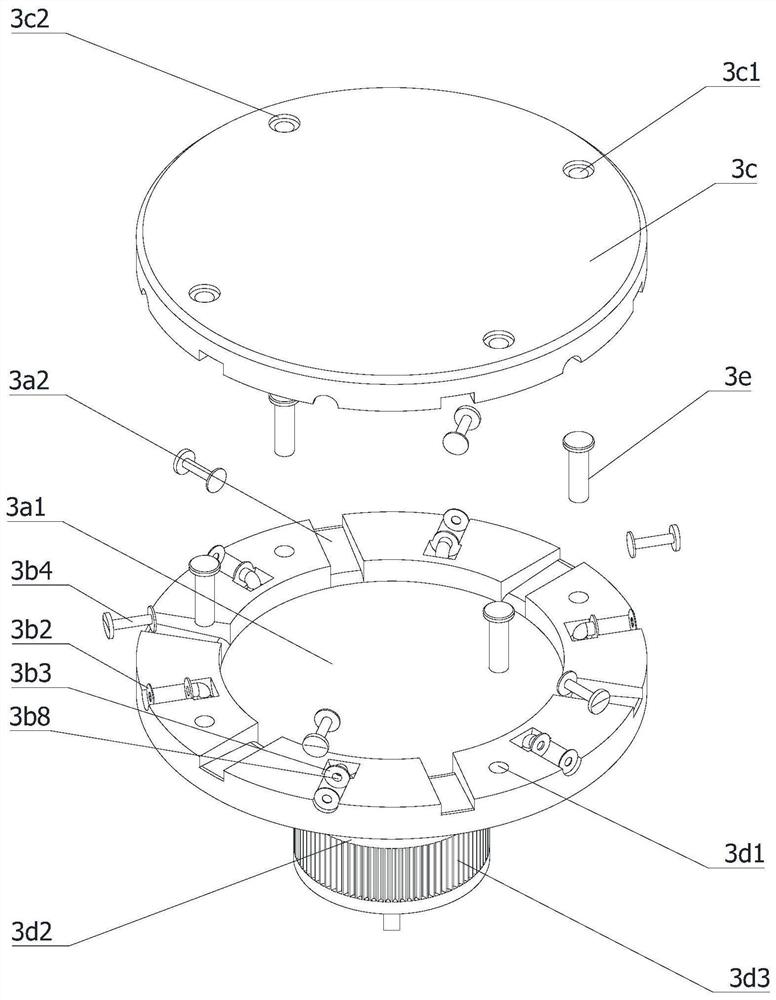

[0040] Such as Figure 1 to Figure 4 As shown, this application provides:

[0041] A gas-assisted overflow optical lens injection mold, comprising an upper mold 1 and a lower mold 2 coaxially arranged, the bottom side of the upper mold 1 is provided with a plurality of upper mold holes 1a, and the upper mold holes 1a surround the central axis of the upper mold 1 Distributed at equal intervals, the top of the lower mold 2 is provided with lower mold holes 2a corresponding to the number and position of the upper mold holes 1a, the upper mold holes 1a and the lower mold holes 2a form a complete injection molding cavity, and the upper mold 1 is provided with injection molding channels 1b, the injection chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com