Device for adjusting tire posture and applying load

A technology of applying loads and tires, which is applied in the direction of automobile tire testing, etc., can solve the problems of complex structure and poor adjustment effect, and achieve the effect of precise action and comprehensive tire posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

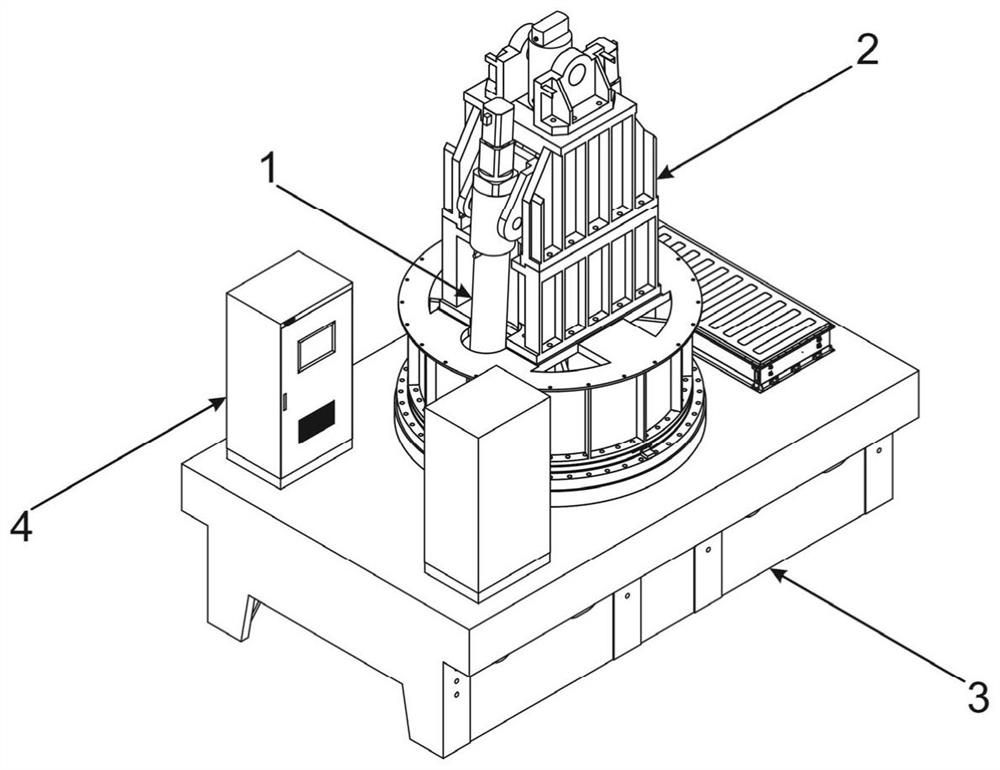

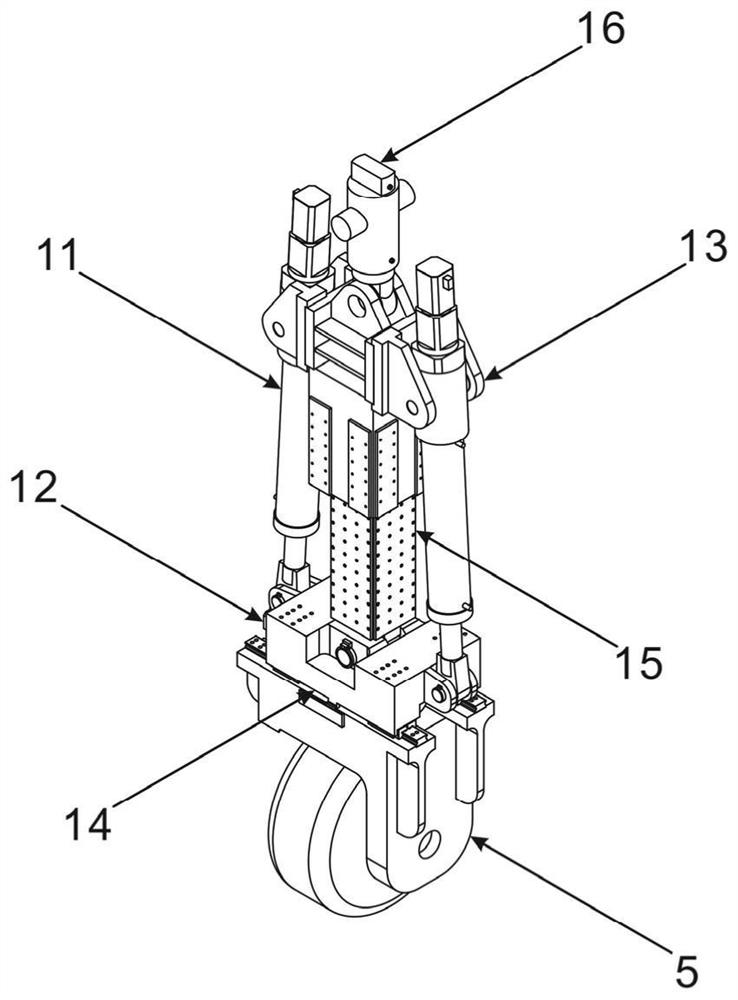

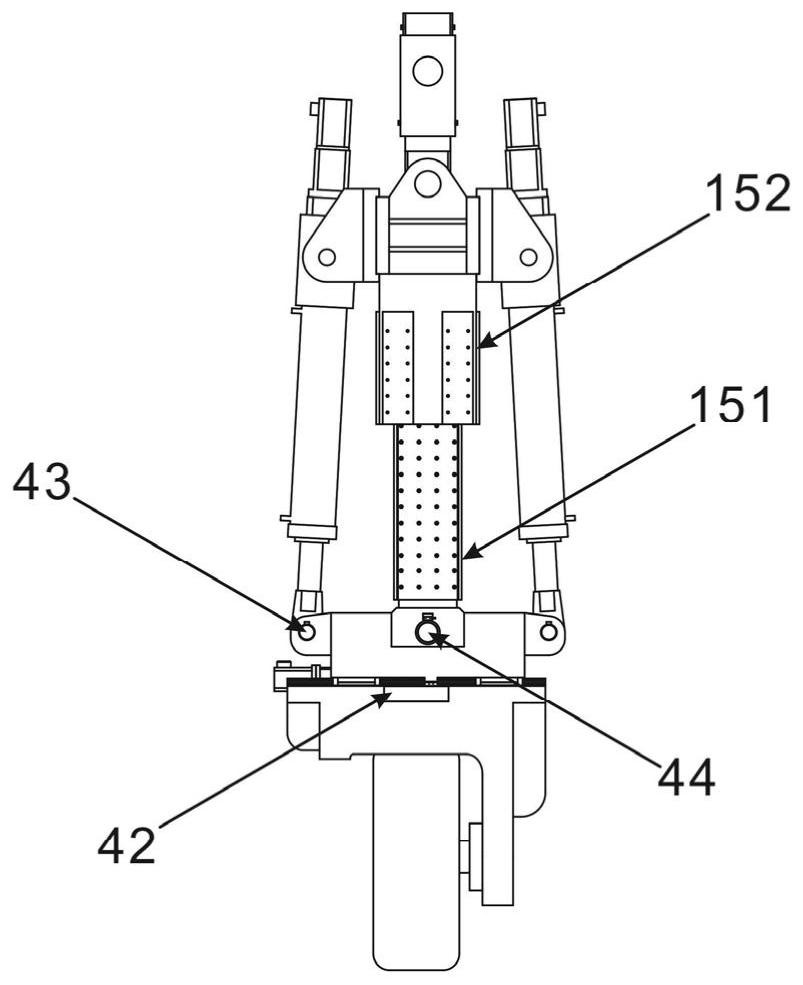

[0047] The present invention provides a device for tire posture adjustment and load application, such as figure 1 with figure 2 As shown, the device for tire posture adjustment and load application includes a moving assembly 1, a rotating assembly 2, a control system 4 and a bearing assembly 3, the moving assembly 1 is arranged on the rotating assembly 2, and the rotating assembly 2 is arranged on the bearing assembly 3 Above, the rotary assembly 2 and the mobile assembly 1 rotate synchronously to adjust the tire rotation angle; the bottom end of the mobile assembly 1 passes through the rotary assembly 2 and the bearing assembly 3, and is connected with the wheel frame connecting seat 5, which is used for the tire The installation of the mobile assembly 1 is used for tire lift, roll and lateral displacement; the mobile assembly 1 and the rotary assembly 2 are connected with the control system 4, and the control system 4 is used for the control of the rotary assembly 2 and the...

Embodiment 2

[0101] The difference between embodiment 2 and embodiment 1 is: as Figure 16-Figure 19 As shown, the number of buffer mechanisms 16 is set to two, which are symmetrically arranged on both sides of the upper support member 13 .

[0102] The upper support member 13 is arranged vertically, and its two sides are symmetrically provided with fourth mounting seats 132 , and the buffer end of the buffer mechanism 16 is hingedly arranged on the fourth mounting seats 132 .

[0103] The upper support seat assembly 211 is set as a second upper support 2114, the second upper support 2114 is set in a block shape, hollow structure, penetrates up and down, and forms an accommodating cavity 2113 inside, and the second upper support 2114 is detachably arranged on the support base 2121 , the upper support 13 is located above the second upper support 2114, and the second upper support 2114 is provided with a sixth mounting seat 21141 on the opposite side walls of both sides, the structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com