Calibrating device for horizontal guide rod magnetic floater liquid level meter

A magnetic float and verification device technology, applied in the field of liquid level gauge, can solve the problems of cumbersome operation and high-altitude operation, and achieve the effect of easy operation and accurate measurement of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

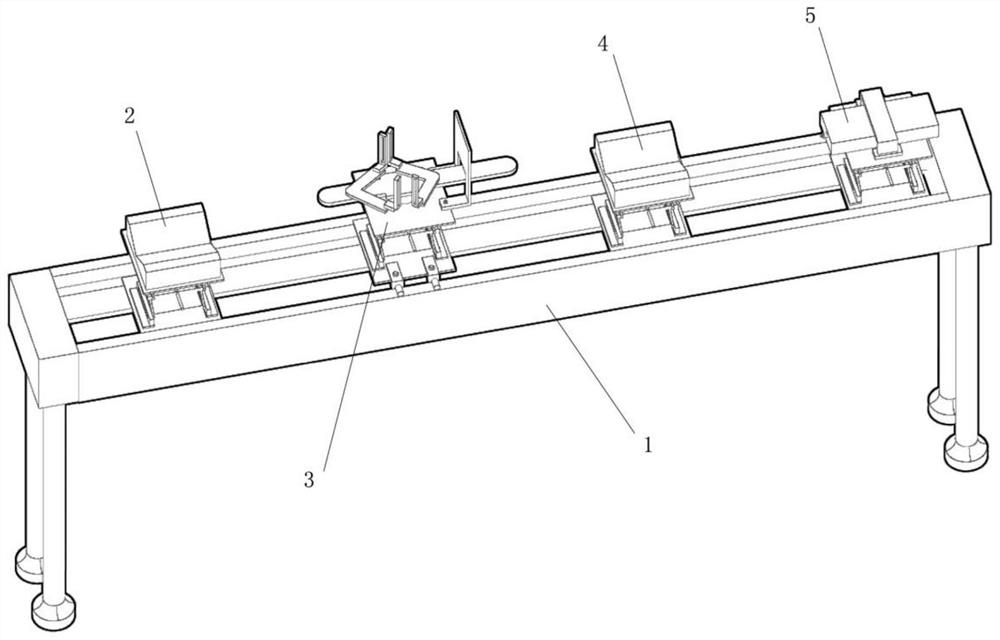

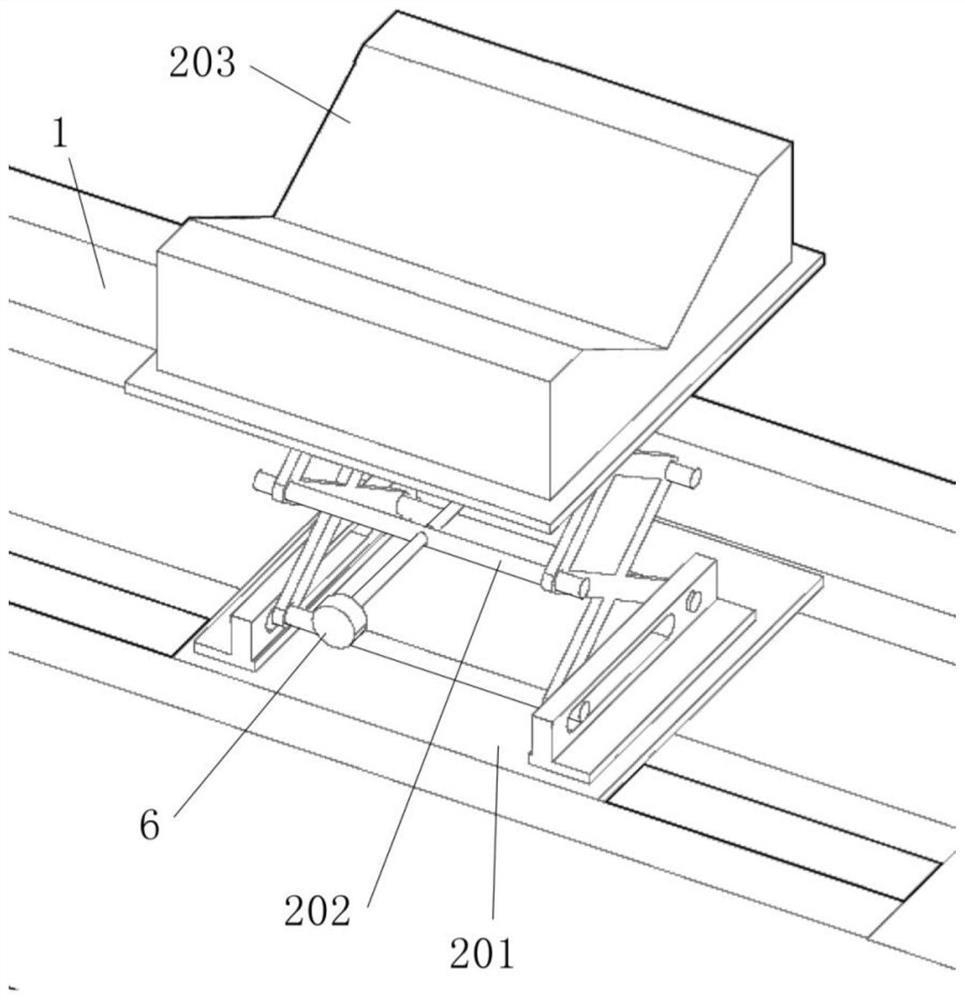

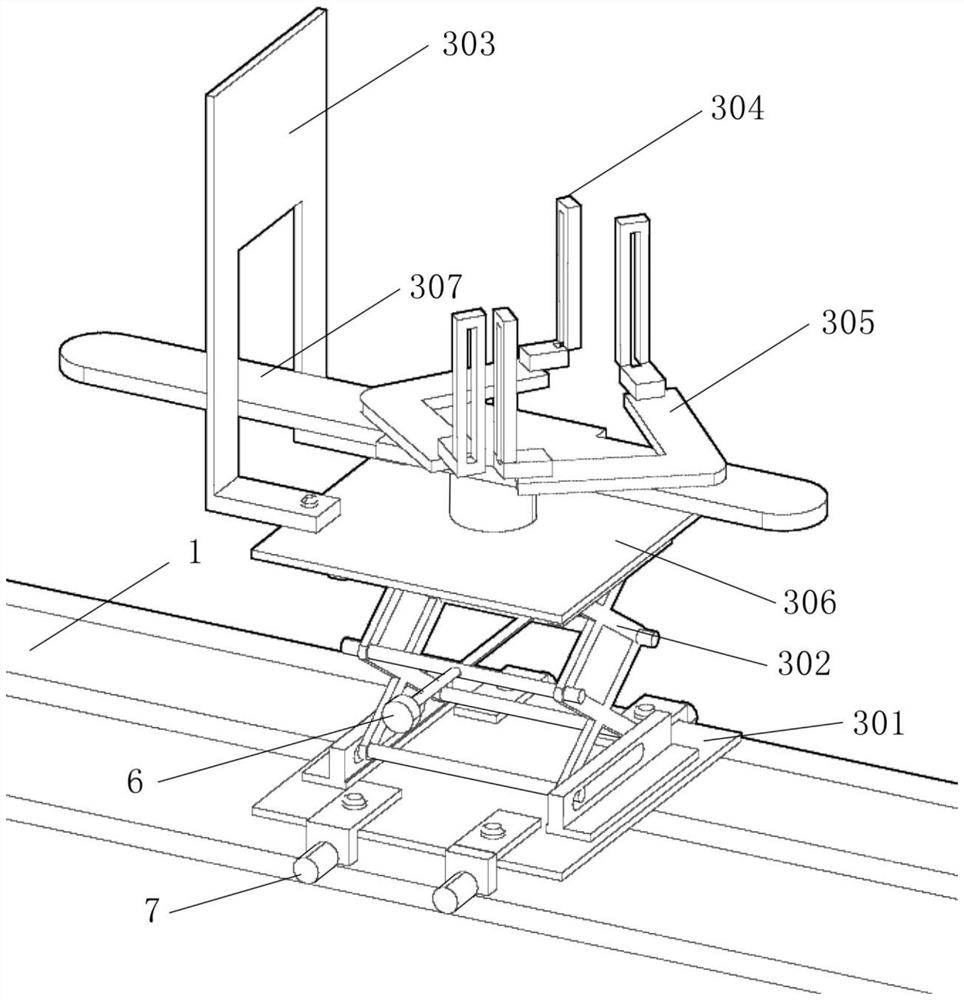

[0030] Example: see attached Figure 1-4 , a horizontal guide rod magnetic float liquid level gauge verification device, including a precision linear guide rail base 1, a liquid level gauge bracket, a movable module 3 and a laser ranging module 5; the liquid level gauge bracket includes an upper limit bracket Frame 2 and lower limit bracket 4, the movable module 3 includes a reflector 303 and a four-claw floating ball fixture 304; the upper limit bracket 2 and the movable module are sequentially installed on the precision linear guide base 1 from left to right 3. The lower limit bracket 4 and the laser distance measuring module 5; the liquid level gauge is placed horizontally on the upper limit bracket 2 and the lower limit bracket 4, and the guide rod part of the liquid level gauge passes through the reflective plate 303, The liquid level float ball of the liquid level gauge is clamped by the four-claw floating ball clamp 304; the laser distance measuring module 5 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com