Multi-sensor cooperative wind driven generator yaw brake pad wear detection system and method

A wind turbine, multi-sensor technology, applied in wind turbines, wind turbine monitoring, wind power generation, etc., can solve the problems of single brake pad detection method, hidden dangers of equipment safety, unfavorable safe and stable operation of wind power generation, etc. Inspection pressure and labor cost, high reliability, and the effect of avoiding inspection operations in confined spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0054] The invention provides intelligent detection for the yaw brake pad of the wind power generator, and improves the safety of the brake system of the wind power generator.

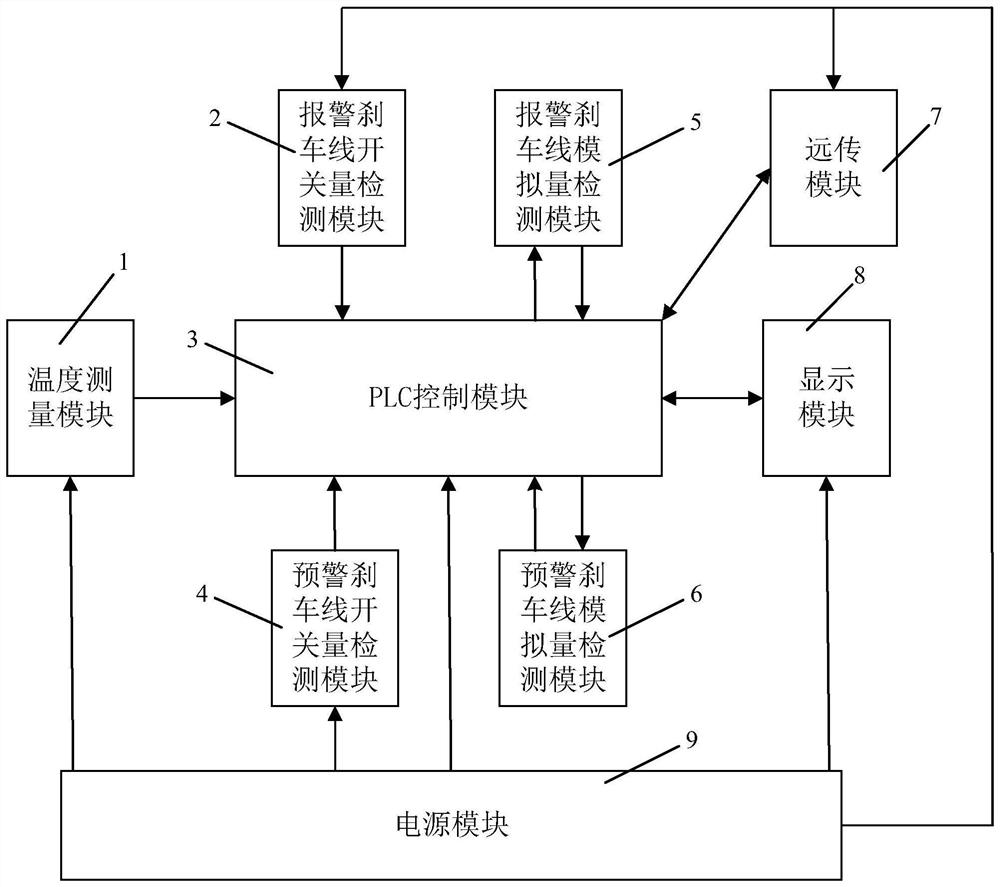

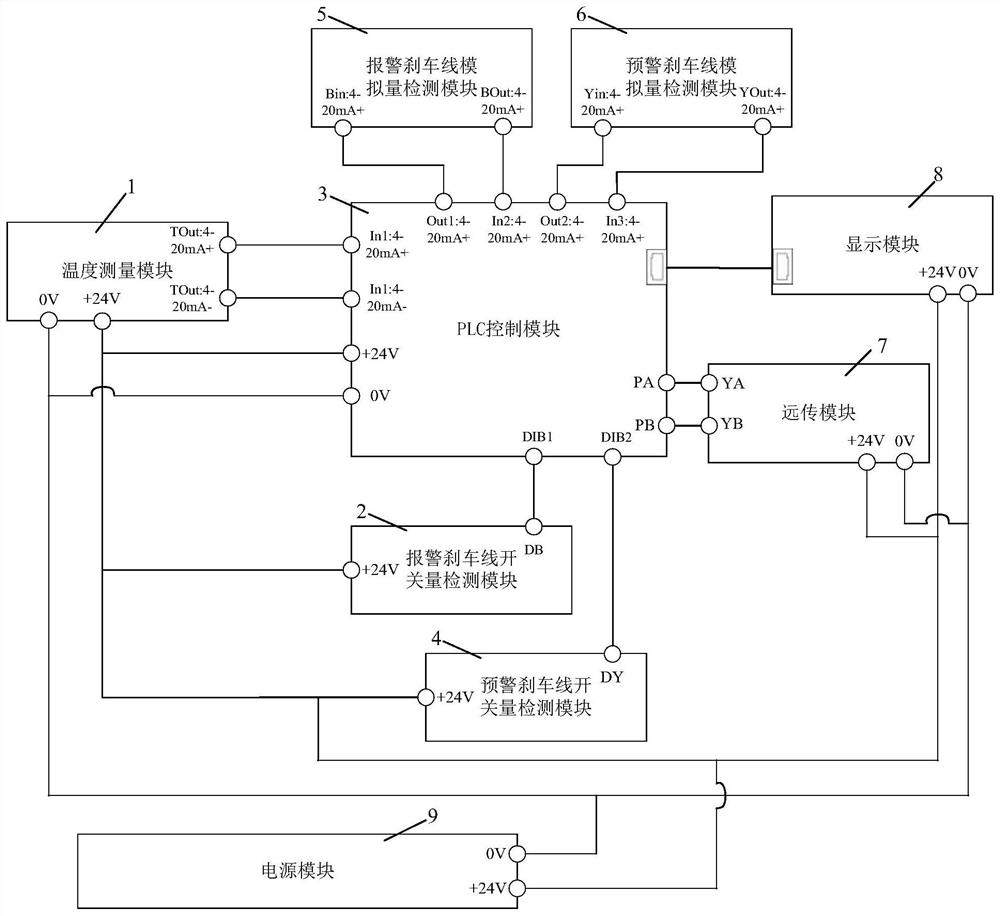

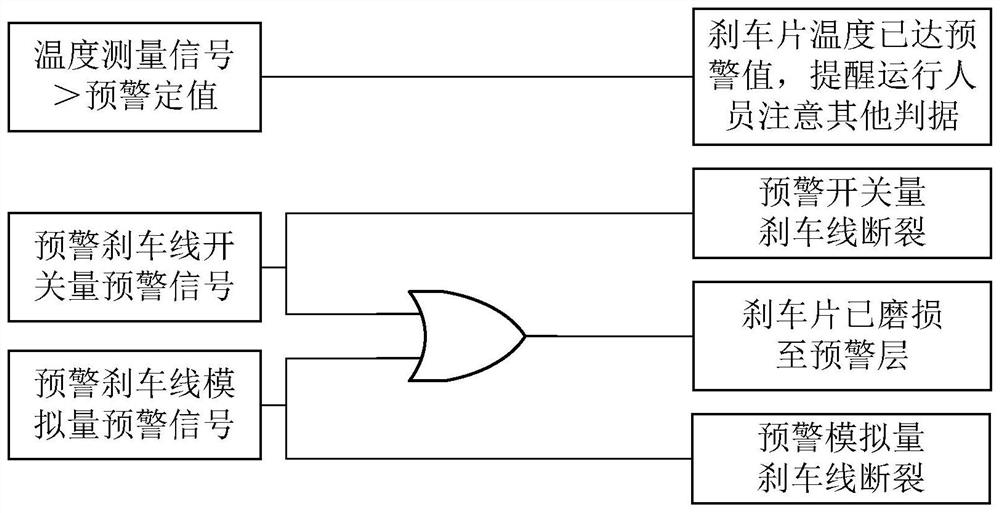

[0055] The present invention is a multi-sensor collaborative wind power generator yaw brake wear detection system, such as figure 1 As shown, it includes a temperature measurement module 1, an alarm brake line switch detection module 2, a PLC control module 3, an early warning brake line switch detection module 4, an alarm brake line analog detection module 5, an early warning brake line analog detection module 6, A remote transmission module 7 and a display module 8; wherein, the temperature measurement module 1 is preset in the brake pad, and the temperature measurement module 1 outputs an analog signal connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com