Lifting hook device and lifting method

A hoisting method and hook technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of low strength against accidental impact loads, hanging objects cannot be smoothly detached from the hook cavity, poor safety and reliability, etc., to achieve operational Convenience, simple structure, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

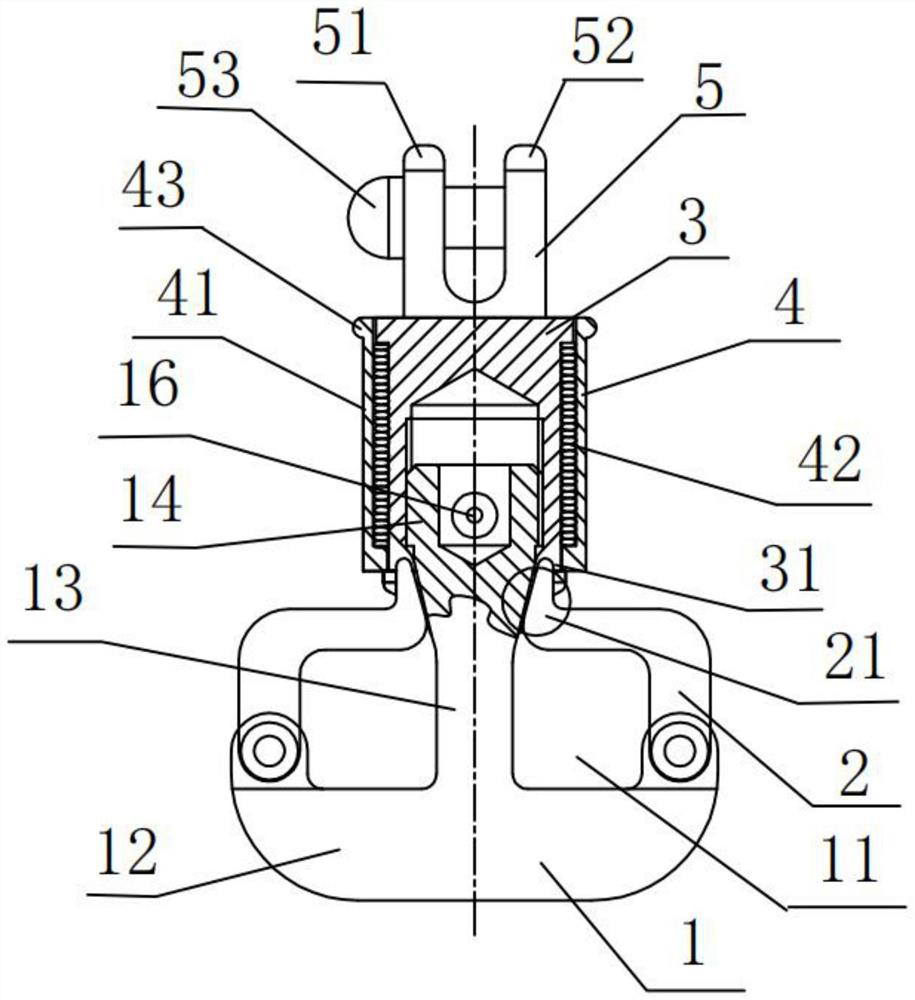

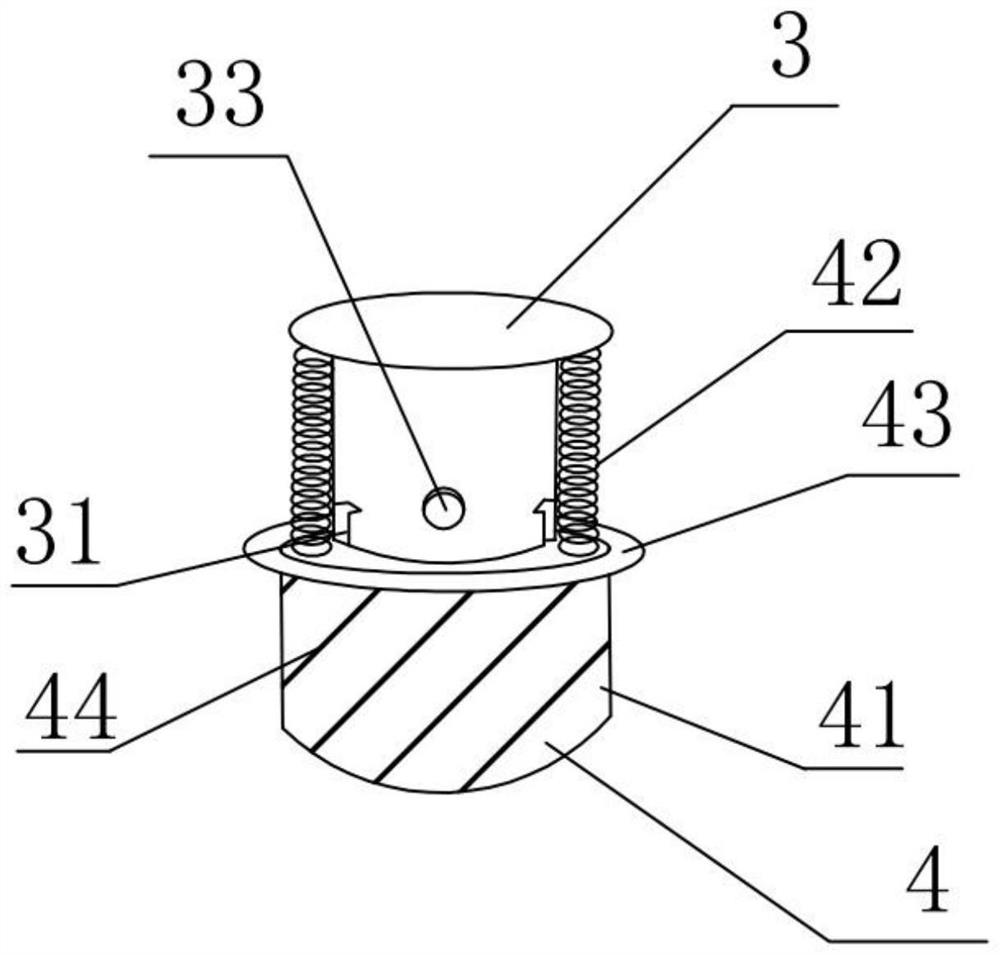

[0046] like figure 2 and image 3 As shown, the locking part 4 includes a locking sleeve 41 axially sleeved outside the connecting part, and a vertically arranged compression spring 42 located in the gap between the locking sleeve 41 and the connecting part 3. The height of the locking sleeve 41 is greater than or It is equal to the height of the connecting part 3, so that the compression spring 42 is completely covered in the gap. During installation, the bottom of the locking sleeve 41 can be against the upper surface of the top of the second connecting end 13, and the top of the locking sleeve 41 can extend upwards along the top of the connecting part 3; The inner extension of the bottom of 41 is against each other, and the top of the clip spring 42 is against the extension of the top of the connecting part 3. The bottom of the clip 41 is pressed downward by the clip spring 42 so that the clip 41 will move the free end of the movable knuckle 2. The hook point 21 is close...

Embodiment 2

[0065] like Figure 4 As shown, the locking part 4 in the first embodiment can also be a movable sleeve 45 with an internal thread on the inner wall, the height of the movable sleeve 45 is less than or equal to the height of the connecting part 3, and the outer wall of the connecting part 3 is equipped with External thread, during installation, the bottom of the movable sleeve 45 can abut against the upper end surface of the top of the second connecting end 13, and the top can abut against the extension edge of the top of the connecting part 3, and the movable sleeve 45 can pass along the connecting part. 3 is rotated up and down to open and close the limit groove 31, and the movable sleeve 45 seals the hook point 21 of the free end of the movable knuckle 2 in the limit groove 31, and by rotating the movable sleeve 45, the movable hook is realized. Tongue 2 has a limit fixing and release function. This locking method is more convenient for the operator to control the up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com