Automatic device for desalting and rough washing of pickles

An automated device and desalination technology, applied in applications, food processing, food science, etc., can solve the problems of slowing down the subsequent process of kimchi preparation, reducing the efficiency of desalination and cleaning, affecting the taste of kimchi, etc., to reduce losses, improve reputation, and reduce impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

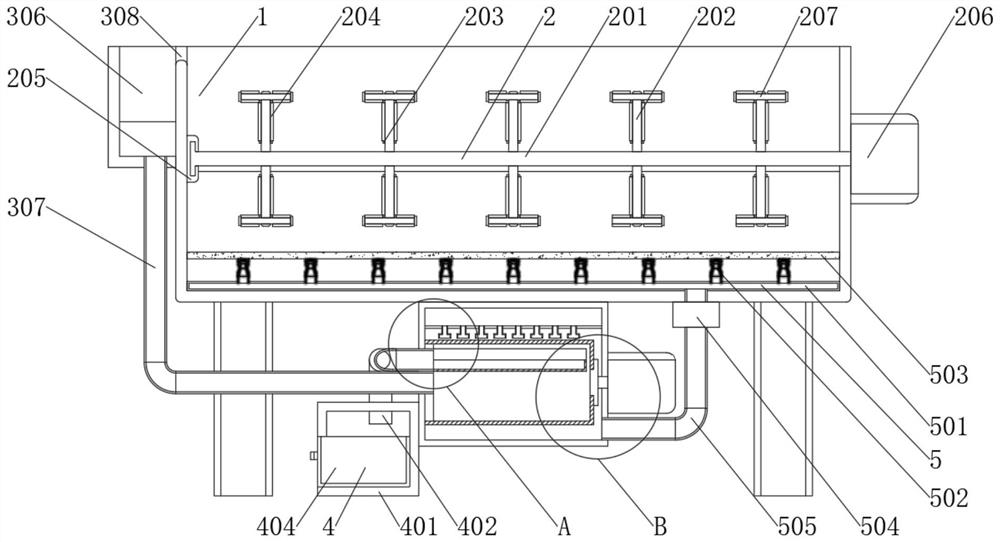

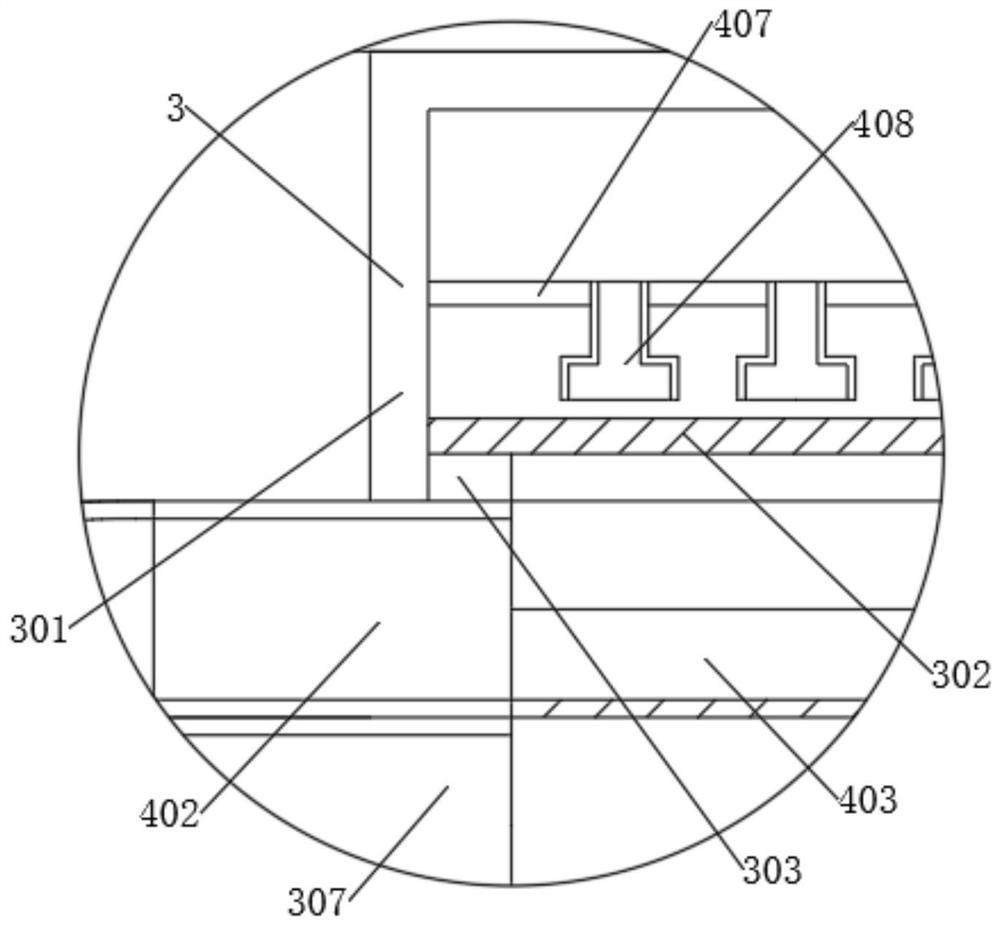

[0048] The invention discloses an automatic device for desalination and coarse washing of pickles. Figure 1-Figure 8 As shown, it includes: desalination coarse cleaning chamber 1, agitation type cleaning mechanism 2, rolling type impurity removal mechanism 3, circulation type impurity removal mechanism 4 and circulation type synergistic mechanism 5.

[0049] refer to Figure 1-Figure 5 As shown, the desalination coarse cleaning chamber 1 is provided with an agitating cleaning mechanism 2. The agitating cleaning mechanism 2 includes an agitating main shaft 201, which can drive the agitating auxiliary shaft 202 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com