Expansion valve

A technology of expansion valve and defrost valve, applied in the field of expansion valve, can solve the problem of high manufacturing cost, and achieve the effects of reducing pressure relief, reducing manufacturing cost and increasing moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

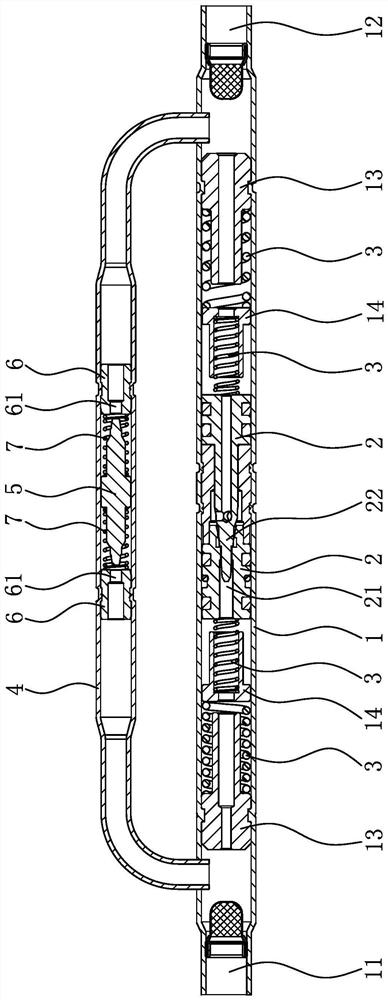

[0046] Such as figure 1 As shown, an expansion valve includes a main valve body 1 and a defrosting valve body 4. Both the main valve body 1 and the defrosting valve body 4 are tubular. One end of the main valve body 1 is a cooling inlet 11, and the other end is a heating inlet. The inlet 12 and the two ends of the main valve body 1 are fixed with limit sleeves 13, and two main valve cores 2 capable of sliding are arranged between the two limit sleeves 13, and the gap between the main valve core 2 and the limit sleeve 13 A spring seat 14 is arranged between, a main spring 3 is arranged between the spool and the spring seat 14, a main spring 3 is also arranged between the spring seat 14 and the limit sleeve 13, and a joint is opened on one of the main spool 2. Orifice 21, the other main valve core 2 has a columnar plug joint 22 on the end surface. A throttling channel is formed between them, and in the process of cooling or heating, the pressure difference between the two ends ...

Embodiment 2

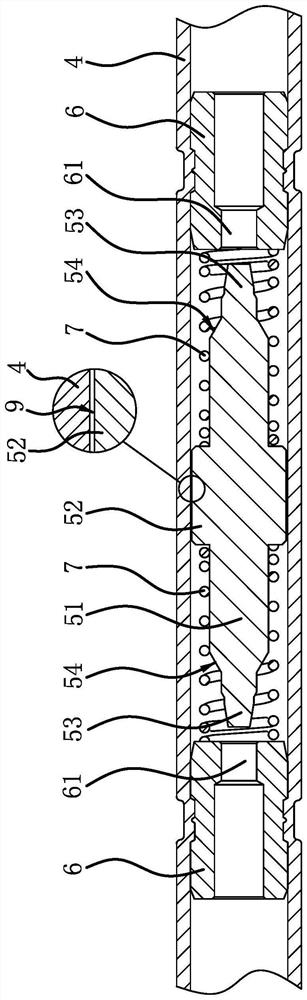

[0052] The structure of the expansion valve is basically the same as that of Embodiment 1, the difference is that Figure 4 , Figure 5 , Figure 6As shown, the defrosting valve body 4 is also provided with a spacer 8 along the length direction. The spacer 8 is made of steel sleeves. The flow hole 61 communicates with the inner hole of the spacer 8. The outer diameter of the spacer 8 is smaller than the inner diameter of the defrosting valve body 4. The spacer 8 and the defrosting valve body 4 are coaxially arranged so that the outer peripheral surface of the spacer 8 is in contact with the defrosting valve body. A return channel 9 is formed between the inner peripheral surfaces of the body 4 , the defrosting valve core 5 is arranged in the spacer 8 , and the outer peripheral surface of the guide part 52 is slidingly fitted with the inner peripheral surface of the spacer 8 . The spacer 8 is provided with two return ports 81 along the length direction, the return ports 81 com...

Embodiment 3

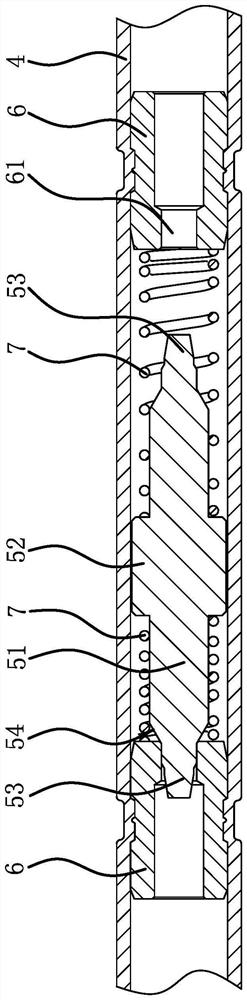

[0054] The structure of the expansion valve is basically the same as that of Embodiment 1, the difference is that Figure 7 , head 8, Figure 9 As shown, the defrosting valve body 4 is also provided with a spacer 8 along the length direction. The spacer 8 is made of steel sleeves. The orifice 61 communicates with the inner hole of the spacer 8, the outer peripheral surface of the spacer 8 fits the inner peripheral surface of the defrosting valve body 4, the defrosting valve core 5 is arranged in the spacer 8, and the outer peripheral surface of the guide part 52 is in contact with the spacer 8, the inner peripheral surface is slidingly fitted, and the axial middle part of the spacer 8 is provided with a strip-shaped return port 81 in the axial direction. The axial length of the return port 81 is greater than the axial length of the guide part 52. Under the action of the guide part 52 is located in the middle of the return port 81, the width of the two ends of the return port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com