Cross bow

A crossbow and cross technology, applied in the field of bow and arrow manufacturing, can solve the problems of high cost, high bowstring emission, noise, etc., and achieve the effect of speed increase and easy winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

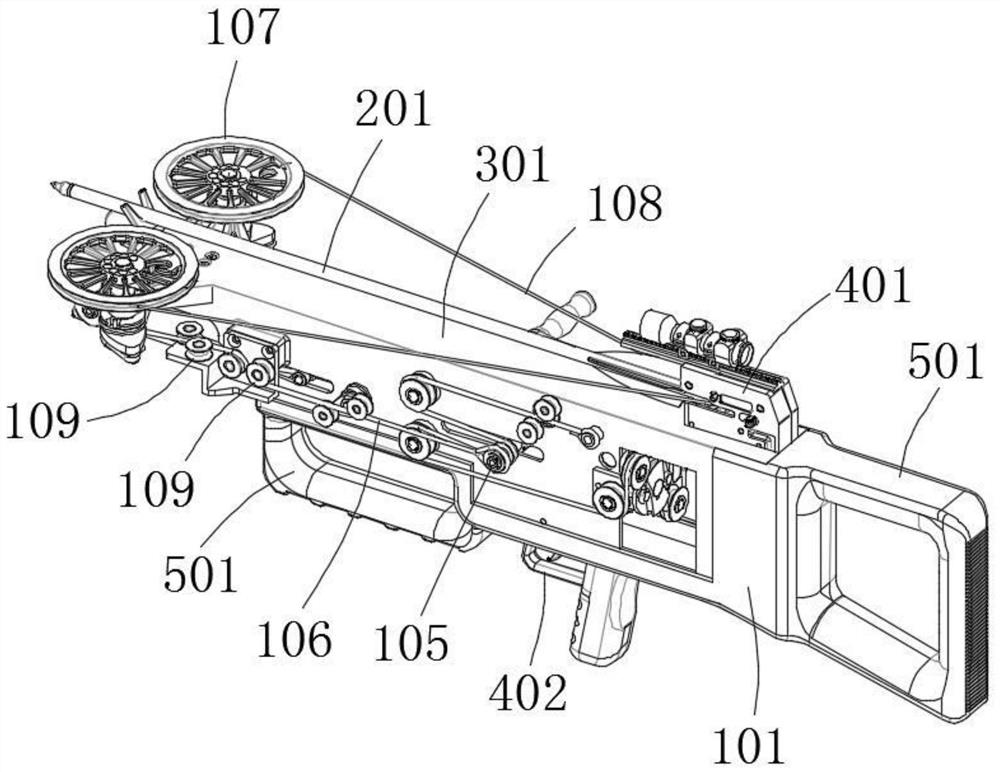

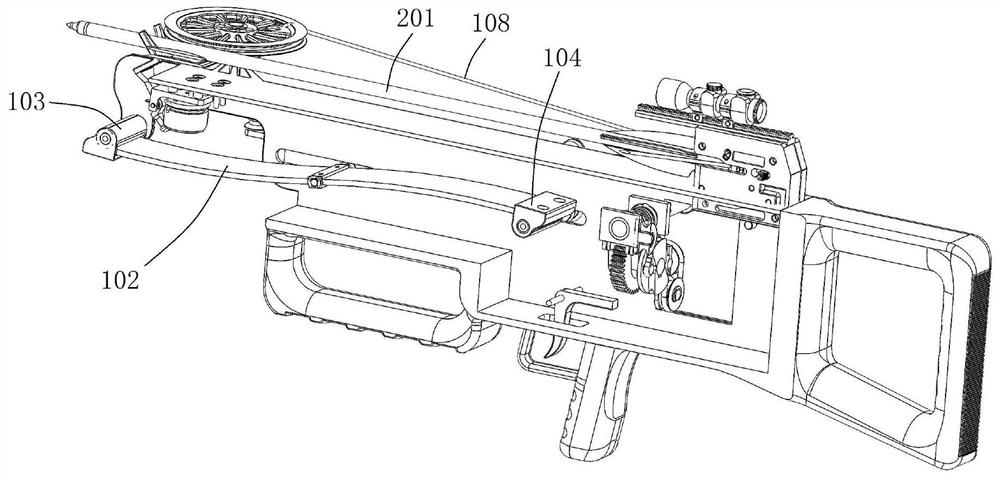

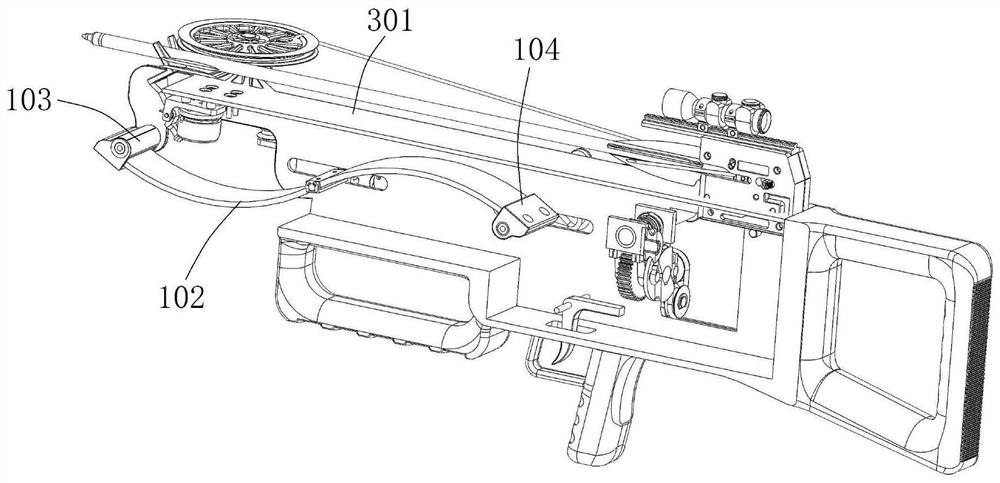

[0034] Such as Figure 1-Figure 3 As shown, a crossbow includes a casing 101, on which is provided an arrow path 301 for placing arrows 201, and a trigger 401 is installed at the root of the arrow path 301, and a corresponding position on the casing 101 is provided with a There is a handle 501 to be held, and a trigger switch 402 is arranged at the handle 501. A bow arm 102 is arranged inside the housing 101. The front end of the bow arm 102 is a fixed end 103 and is relatively fixed on the housing 101. The bow arm 102 The rear end of the bow arm 102 can move relative to the housing 101 to form a moving end 104. When the bow arm 102 is squeezed, the moving end 104 (rear end) of the bow arm 102 can move forward so that the bow arm 102 is compressed and bent.

[0035] The bow arm 102 includes two curved sections, one is an upward curved section and the other is a downward curved section. When the bow arm 102 is squeezed, the two curved sections bend in opposite directions so tha...

Embodiment 2

[0046] A crossbow, including the wave-shaped bow arm 102 , the winding wheel 107 , the main string 108 , the driving string 106 and the double-groove guide wheel 105 as described in the first embodiment. A pre-compression structure 601 is also included. Such as Figure 7 The shown preloading structure 601 includes a worm gear structure. A string receiving wheel 603 is installed coaxially with the worm wheel 602 on the worm wheel 602 , and the string receiving wheel 603 is driven to rotate synchronously when the worm wheel 602 rotates. The string storage wheel 603 is provided with two fixing posts 6031 , and the string storage wheel 603 is provided with a wire groove 6032 . An auxiliary string 605 is respectively fixed on the two fixing columns 6031 , and when the string receiving wheel 603 rotates, the auxiliary string can be wound in the guide groove 6032 .

[0047] The pre-compression structure 601 also includes a plurality of guide wheels 606 and a plurality of guide posi...

Embodiment 3

[0051] A crossbow, including the wave-shaped bow arm 102, the reel 107, the main string 108, and the driving string 106 as described in the first embodiment. It also includes the pre-compression structure 601 as described in the second embodiment. In addition, this embodiment also includes a pre-tightening wheel 701 .

[0052] Such as Figure 9 , Figure 10 The pre-tightening wheel 701 shown includes more than two guide wheels 702 , a bracket 703 connecting the guide wheels 702 , an elastic member 704 , a bracket seat 705 and a central shaft 706 . The pretensioner wheel 701 is installed on the side of the housing 101 and on the path of the secondary chord and the drive chord 106 . Specifically, the bracket base 705 is fixed on the housing 101, and the bracket base 705 is connected with the bracket 703 through the central shaft 706 for rotation. More than two guide wheels 702 are installed on the bracket 703, and the bracket 703 and the bracket base 705 pass through The ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com