Rotary sawing machine for pipes

A technology for sawing machines and pipes, applied to metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve the problems of pipe surface damage, high noise, and increased transportation costs, and achieve reduced wear and faster sawing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific examples.

[0025] The longitudinal and axial directions mentioned in this embodiment are along the length of the pipe, and the transverse direction is the direction perpendicular to the longitudinal direction.

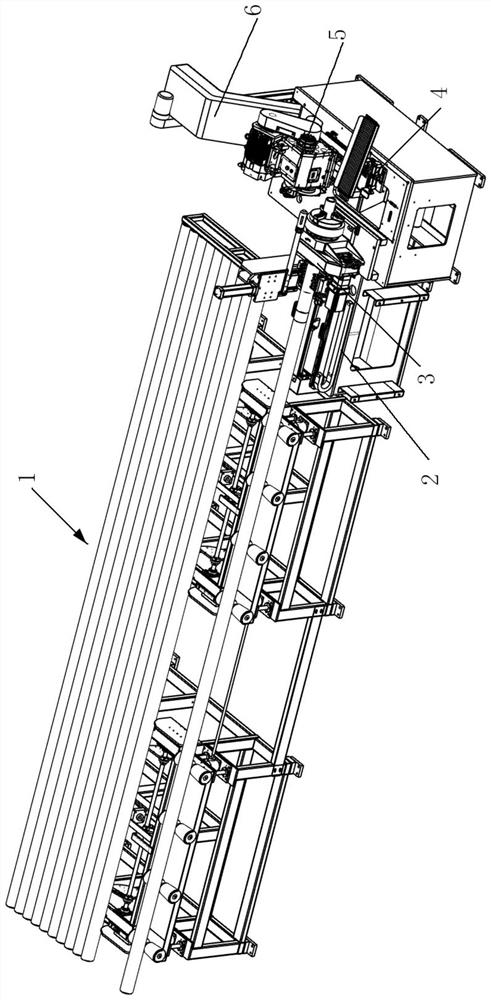

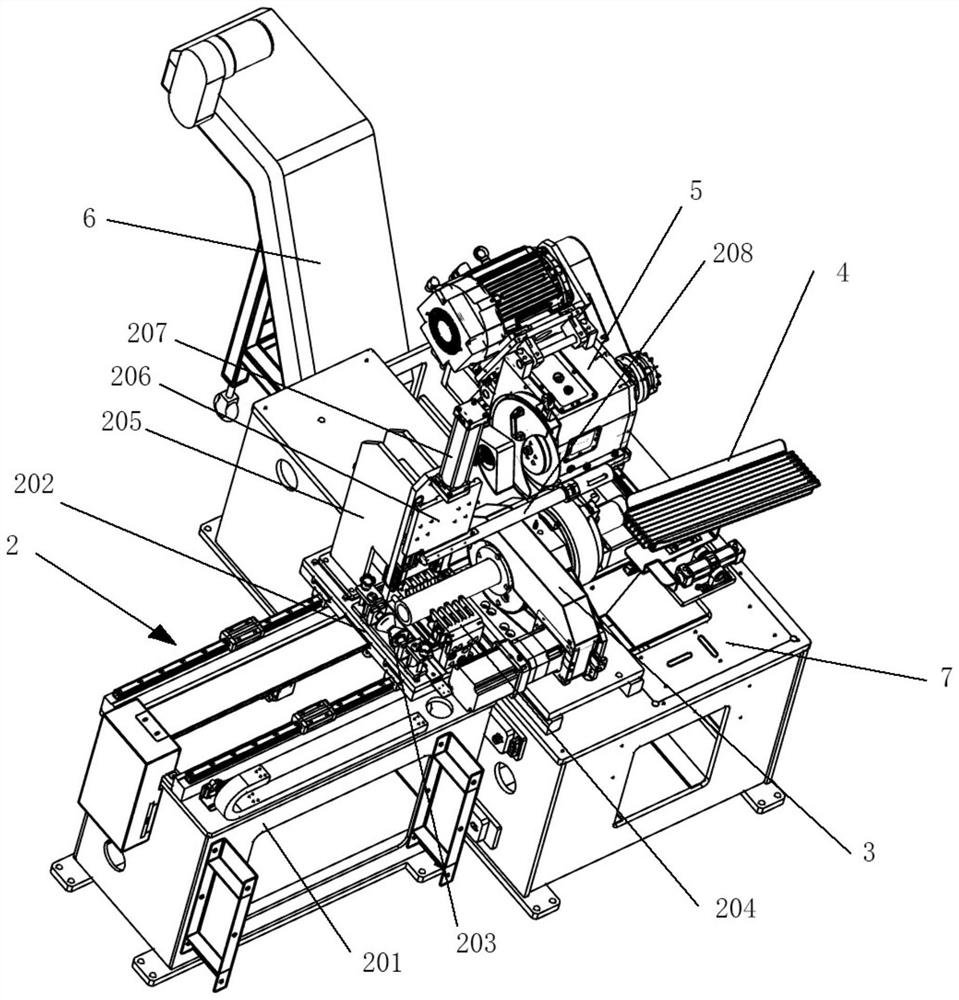

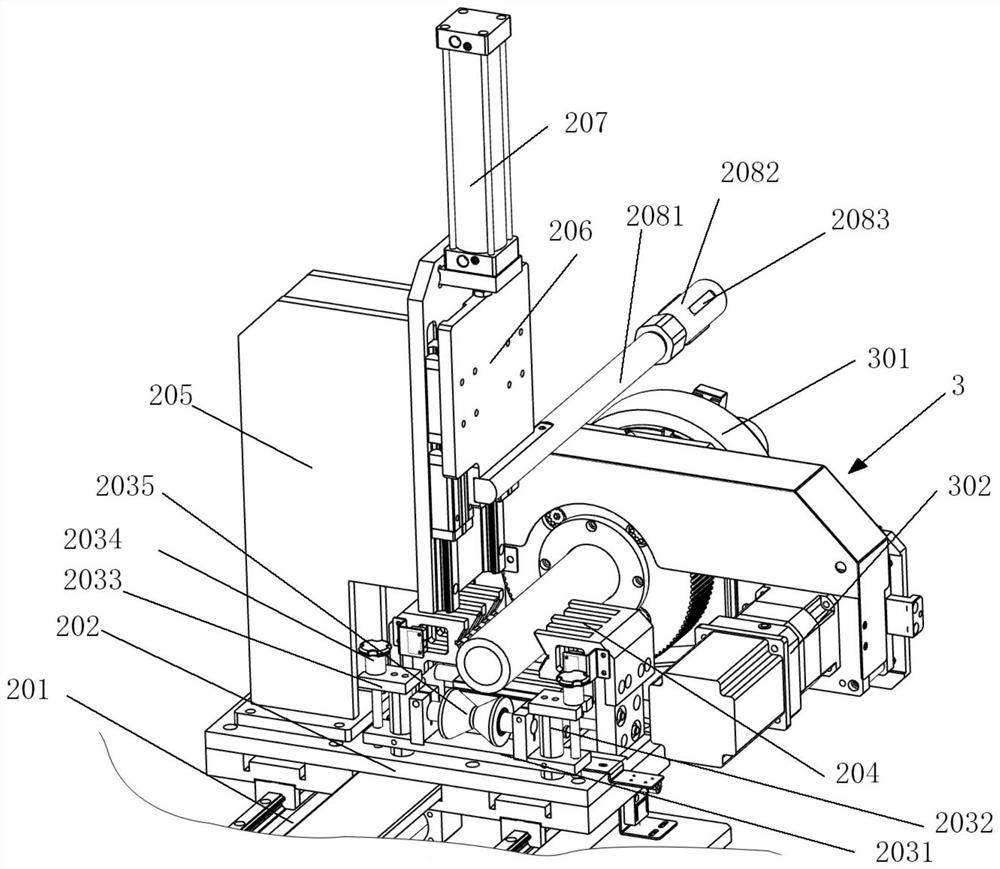

[0026] Such as Figure 1 to Figure 7 As shown, a pipe rotary sawing machine includes an automatic feeding rack 1 for placing pipes, the automatic feeding rack 1 includes a material rack, and an inclined discharge platform 104 is arranged above the material rack. The lower side of the discharge platform 104 on the material rack is provided with a blocking material guide plate 105, the upper end surface of the blocking material guide plate 105 is set as an inclined material guide slope 1052, and the blocking material guide plate 105 is close to the material discharge platform 104. The upstream side is provided with an upstream material guide inclined surface 1051, and a support roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com