Hollow grounding insulation intensive bus duct

A grounding insulation and intensive technology, applied in the field of bus duct, can solve the problems of component damage, inconvenient cleaning, damp environment inside the bus duct, etc., and achieve the effect of avoiding damage and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

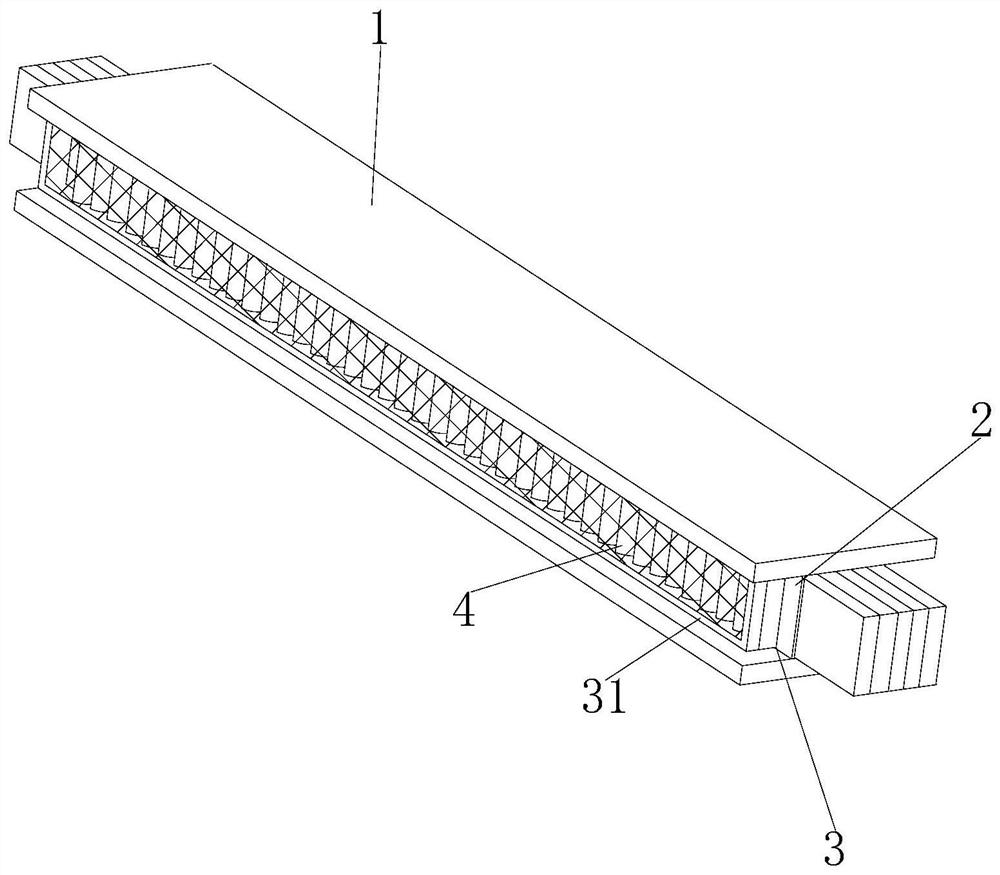

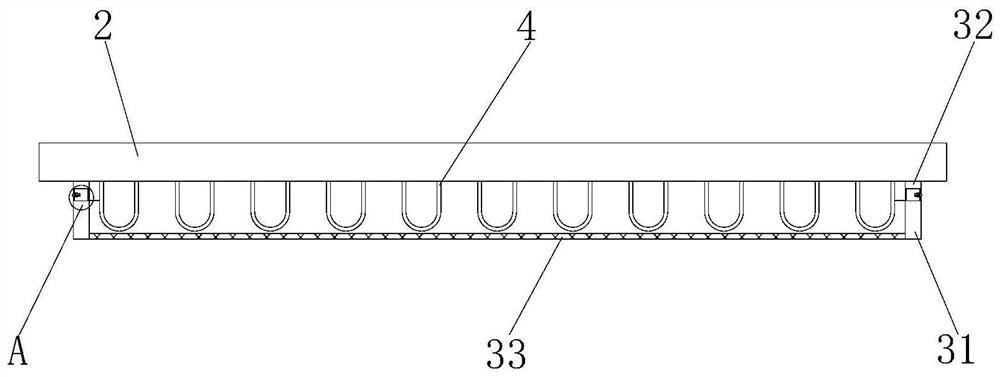

[0027] see Figure 1-6 , the present invention provides the following technical solutions: a hollow grounding insulation-intensive busway, including a cover plate 1, the two sides of the cover plate 1 are connected with side plates 2, and the side walls of the side plate 2 are connected with several U-shaped tubular The heat sink 4 is provided with a dust-proof assembly 3 on the side wall of the side plate 2 and on the periphery of the U-shaped tubular heat sink 4;

[0028] The dust-proof assembly 3 includes a mounting frame 31, a fixed frame 32 and a dust-proof net 33. On the side wall of the side plate 2 and at the periphery of the U-shaped tubular heat sink 4, a fixed frame 32 is connected, and the fixed frame 32 is far away from one side of the side plate 2. An installation frame 31 is arranged on the side, and a dustproof net 33 is connected to the inner side wall of the installation frame 31 .

[0029] Specifically, the dustproof assembly 3 also includes a plug block 34...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that a drying assembly 5 is provided inside the cover plate 1 and the side plate 2, the drying assembly 5 includes a drying bag 52 and a desiccant 57, and the inside of the cover plate 1 and the side plate 2 is provided with Drying bag 52, the interior of drying bag 52 is filled with desiccant 57,

[0036] Specifically, the side of the dry pack 52 close to the cover plate 1 and the side plate 2 is provided with an installation box 51, and the installation box 51 and the dry pack 52 are glued together,

[0037] By adopting the above technical solution, it is convenient to insert the dry bag 52 into the inside of the cover plate 1 and the side plate 2 .

[0038] Specifically, the drying assembly 5 also includes a connecting groove 53, a limiting groove 54, a limiting plate 55 and a connecting block 56. The two ends of the installation box 51 are connected with the connecting block 56, and the side wall of the cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com