Chemical process pump with ultralow vibration value

A vibration value, process pump technology, applied to the components, pumps, pump components of the pumping device for elastic fluid, etc., can solve the problem that the OH2 pump cannot meet the standard requirements, and achieve increased stability and high operation reliability. , The effect of low replacement rate of accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

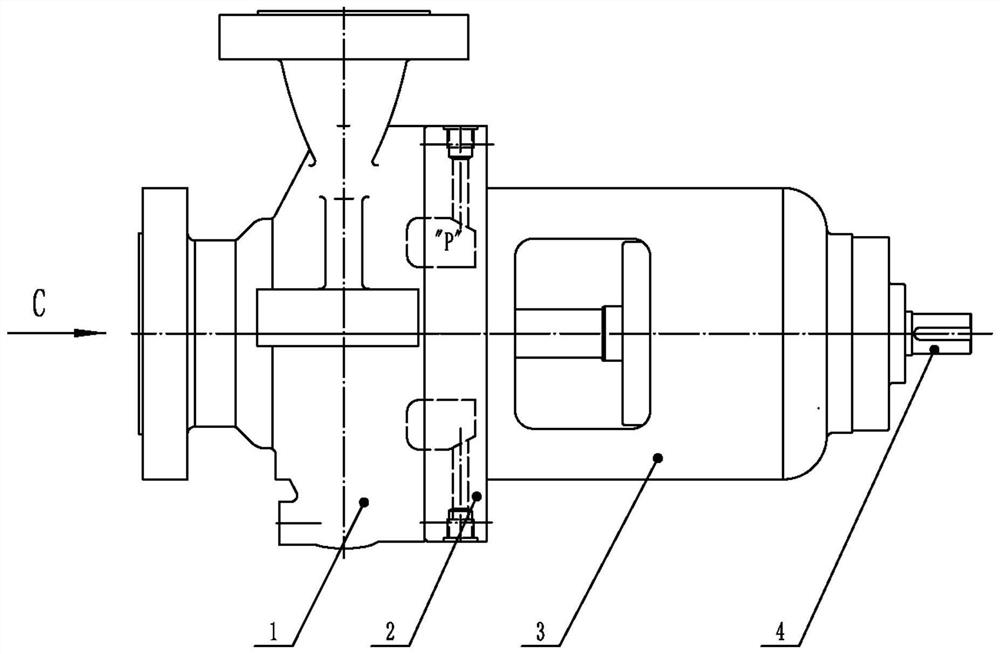

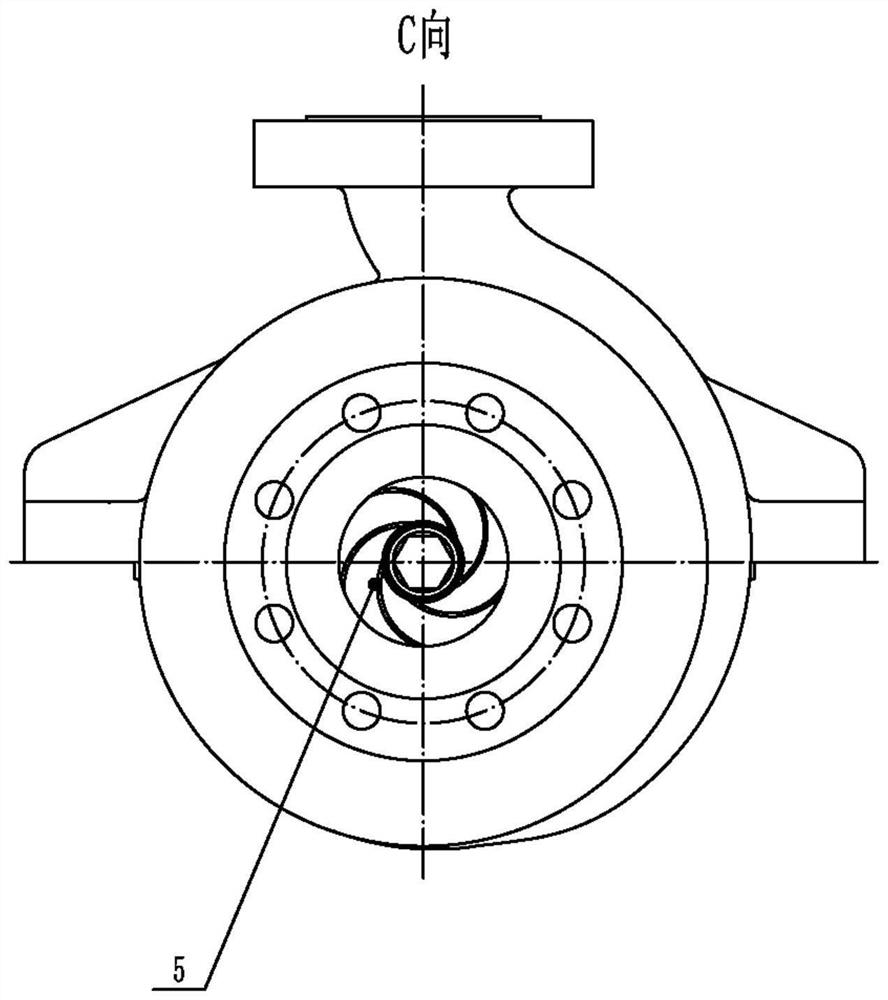

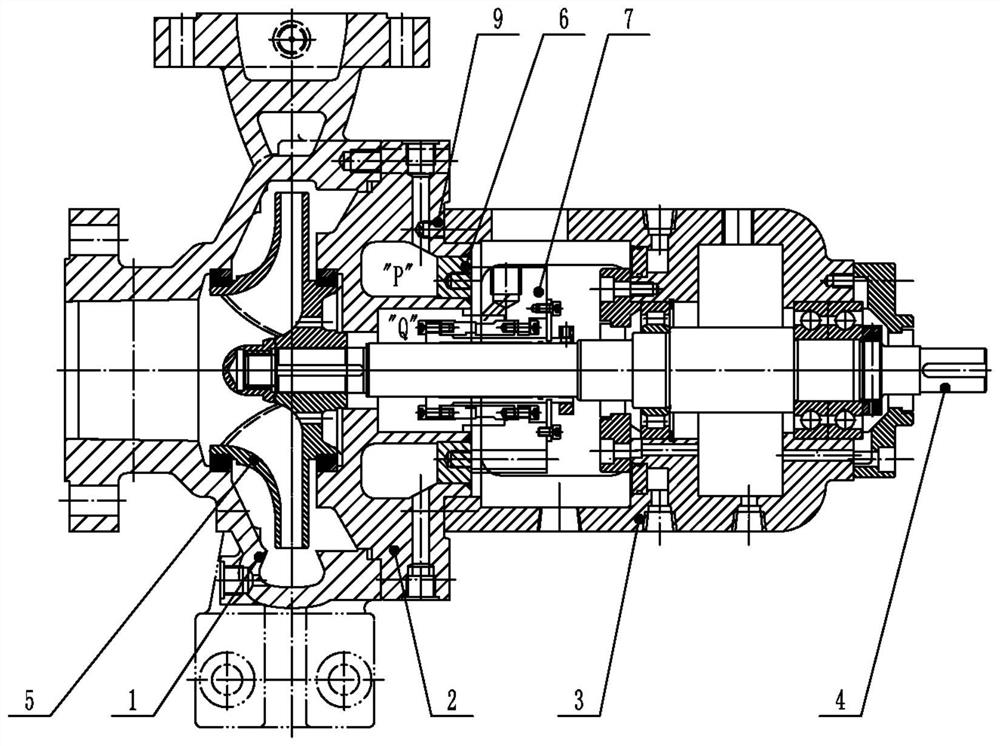

[0024] In order to better understand the purpose, structure and function of the present invention, an ultra-low vibration value chemical process pump of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] Such as Figure 1-Figure 7 As shown, in order to meet the low vibration value standard, the patented product adopts the EU ENISO 13709-2009 standard in design. An ultra-low vibration value chemical process pump of the present invention is characterized in that it includes a pump body 1, a pump cover 2, a bearing body 3, a pump shaft 4, an impeller 5, a cooling chamber cover 6, a mechanical seal, a cooling chamber P and a mechanical seal Cavity Q;

[0026] An ultra-low vibration value chemical process pump, including a pump body 1 and a pump shaft 4, the pump body 1 has a horizontal inlet flange, and a vertical outlet flange, and the inlet and outlet flanges implement HG-T20615-2009 steel flange Class 600 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com