Wall splicing mechanism for fabricated building

A prefabricated and architectural technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of time-consuming and laborious splicing, inconvenient installation and disassembly, and affecting the use of walls, etc., to reduce gaps and facilitate operation and use Fast and improve the efficiency of splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

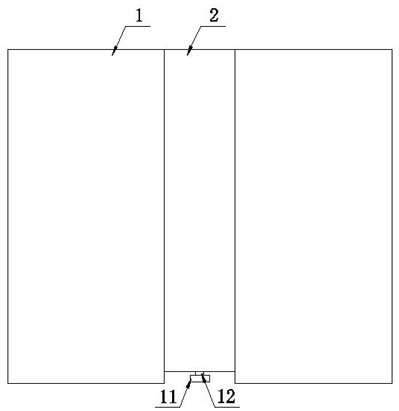

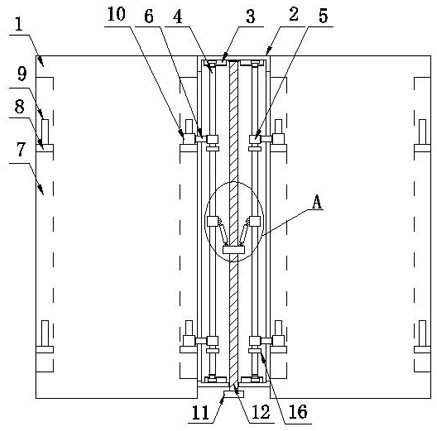

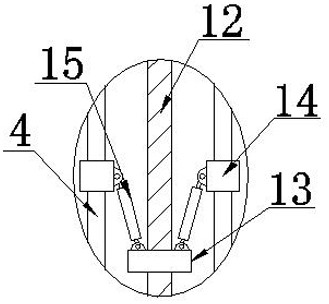

[0017] see Figure 1-Figure 3 , a wall splicing mechanism for prefabricated buildings, including two wall panels 1, a splicing frame 2 located between the two wall panels 1, a chute plate 3, a sliding rod 4, a sliding sleeve 5, a connecting rod 6, Chute 7, fixed plate 8, clamp rod 9, ferrule 10, rotating plate 11, threaded rod 12, internal threaded bearing 13, connecting sleeve 14, support rod 15, baffle plate 16, splicing frame 2 cavity top and bottom Corresponding chute 7 plates 3 are respectively arranged on both sides, and the sliding rod 4 is slidably connected between the two chute 7 plates 3 on the same side through a slider. The top and bottom of the sliding rod 4 are respectively covered with sliding sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com