Cord fabric separating and coiling device of high-platform cutting machine

A technology of coiling device and cutting machine, which is applied in high-pressure cleaning, coiling strips, mechanical cleaning, etc., can solve problems such as difficult cleaning and affecting product quality, and achieve easy cutting, reduce burrs, and reduce dust residue on the surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] see Figure 1-Figure 7 , the present invention provides a technical solution: a cord separation and coiling device for a high platform cutting machine, comprising: a fixed table 1, a dust removal box 2 and a cutting box 3, the top surface of the fixed table 1 is recessed inwardly to form a mounting groove and connected through the mounting groove The conveyor belt 9, the dust removal box 2 and the cutting box 3 are all installed on the top surface of the fixed table 1, the dust removal box 2 is used to remove dust from the surface of the cord, and the cutting box 3 is used to cut the cord;

[0029] The interior of the cutting box 3 is equipped with a cutting mechanism 7 and a heating mechanism. The cutting mechanism 7 is used to cut the cord, and the heating mechanism is used to heat the cord to reduce burrs and debris generated during the cutting process. The top surface of the cutting box 3 is The side is provided with a through hole and an adjustment mechanism is ins...

Embodiment 2

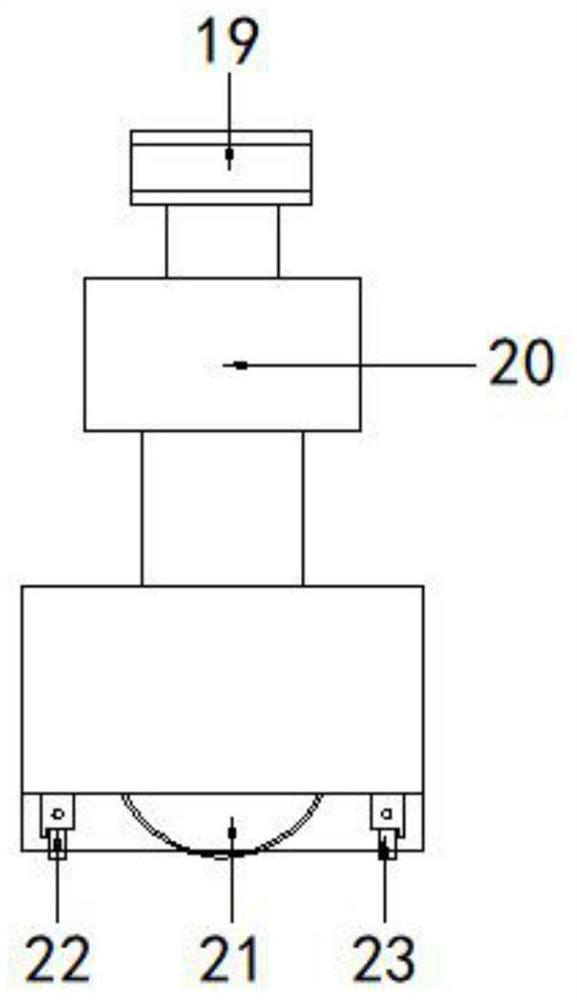

[0036] further improved, such as Figure 4 As shown: two sets of deburring mechanisms are arranged and symmetrically installed at the bottom of the connecting block 20 near the edges of both sides. The deburring mechanism includes an adjusting block 25, a rotating shaft 26, a heating wire 1 23 and two symmetrically arranged fixing plates 22. The adjustment block 25 is arranged between the two fixed plates 22 and is connected to the fixed plate 22 by a rotating shaft 26 in rotation. Roll spring 24, the inner end of plane scroll spring 24 is connected with rotating shaft 26, and outer end is connected with fixed block, and two heating wires one 23 and adjusting block 25 are vertical shape, and it can only rotate to cutting knife 21 directions.

Embodiment 3

[0038] further improved, such as Figure 7 Shown: heating mechanism comprises air guide pipe 29 and air outlet pipe 30, and the inside of air guide pipe 29 is provided with thread groove 31, and the inside of thread groove 31 is provided with heating wire 2 32, and air outlet pipe 30 is provided with several and Vertically connected to the lower end of the air guide pipe 29, the inside of the air outlet pipe 30 communicates with the inside of the air guide pipe 29, and the air inside the air guide pipe 29 is heated by the heating wire 2 32 and transported to the air outlet pipe 30, and finally the air The pipe 30 blows towards the curtain.

[0039] When the present invention is in use, the cord is conveyed by the conveyor belt 9. After the cord moves on the conveyor belt 9, it passes through the cutting box 3 and the dust removal box 2 in sequence. The hot air is used to heat the cord, and then the cord is cut by the cutter 21. The heated cord is easier to cut, and at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com