High-load-bearing sliding rail for drawer type three-dimensional material warehouse

A material warehouse and drawer-type technology, applied in tool storage devices, manufacturing tools, etc., can solve problems such as inability to bear load, fatigue damage of slide rails, waste of manpower, etc., to achieve the degree of strengthening connection firmness, improve load-bearing capacity, and improve the applicability of the device sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

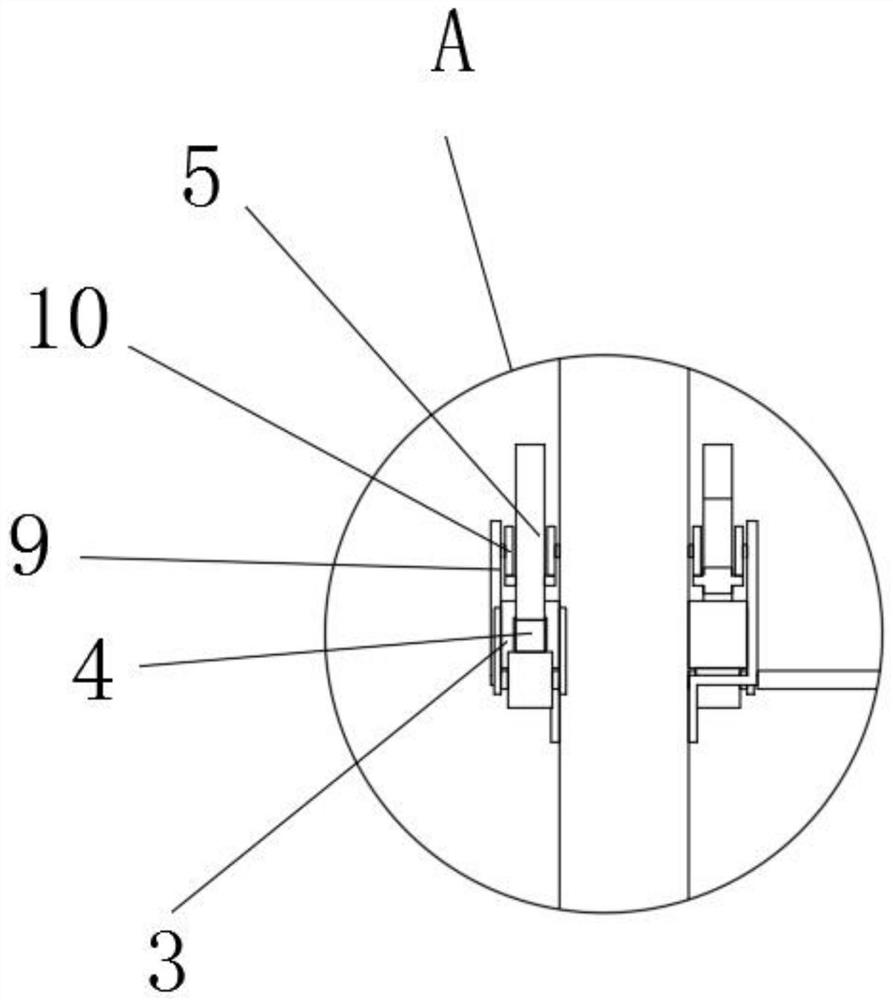

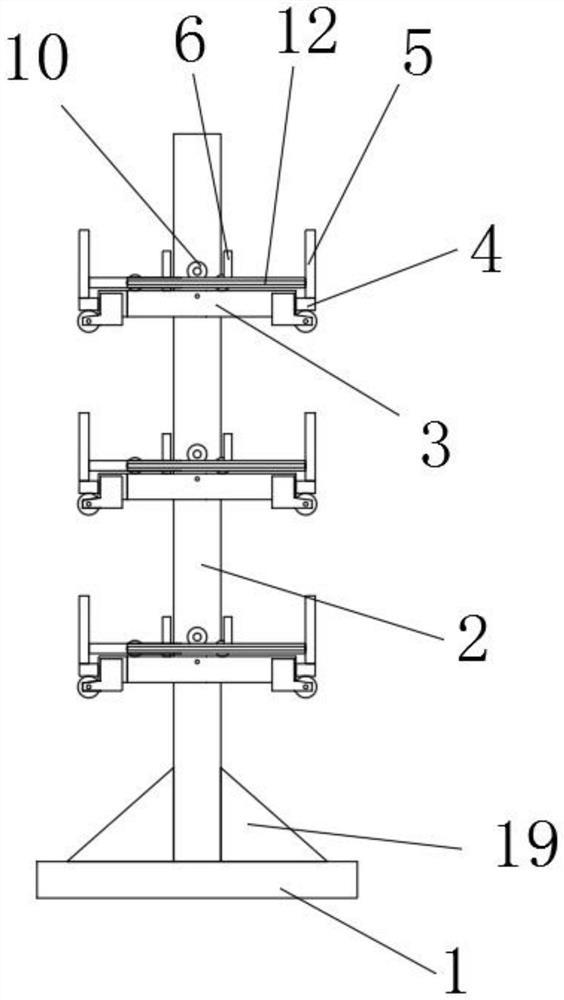

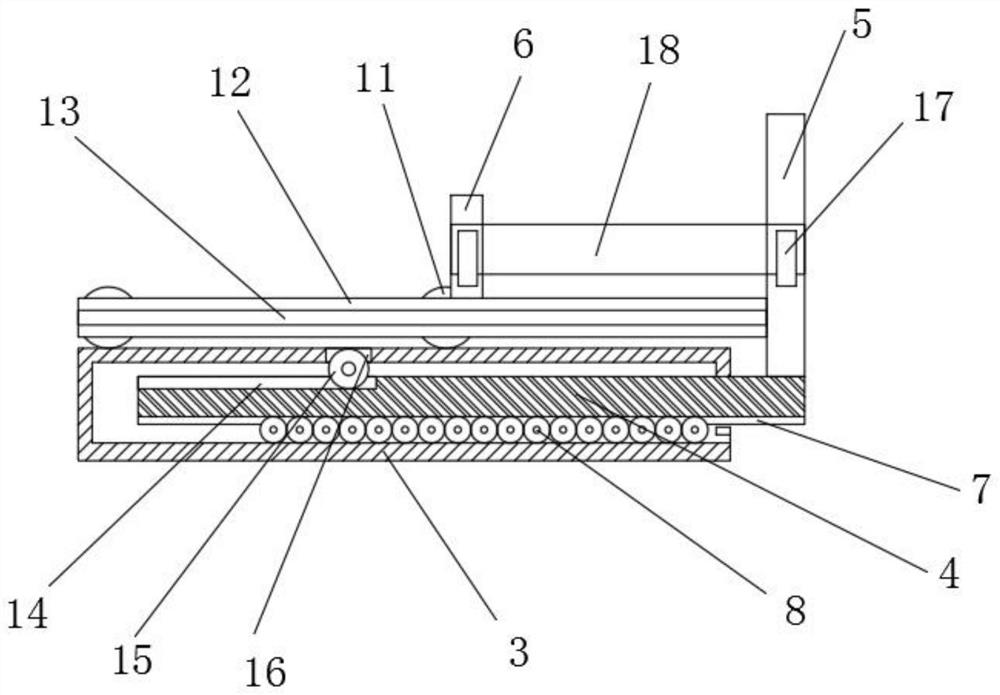

[0033] see Figure 1-4, a high load-bearing slide rail for a drawer-type three-dimensional material warehouse, comprising a base 1, the upper end of the base 1 is fixedly connected with a column 2, the lower end of the column 2 is fixedly connected with a reinforcing rib 19, and the lower end of the reinforcing rib 19 is fixed to the upper end of the base 1 Connection, the reinforcing rib 19 can strengthen the firmness of the connection between the column 2 and the base 1, and improve the bearing capacity of the base 1. The number of the base 1 can be arranged side by side according to the length of the material stored in the material warehouse, and can be selected according to the use requirements. Applicability of the device, both sides of the column 2 are fixedly connected with a plurality of sliding cylinders 3, the sliding cylinders 3 on both sides of the column 2 are respectively aligned horizontally, and arranged at equal intervals in the vertical direction, the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com