Automatic sorting module of test tube sorting machine

An automatic sorting and sorting machine technology, applied in sorting and other directions, can solve the problems of small picking and transferring range, low efficiency, and affecting hospitals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

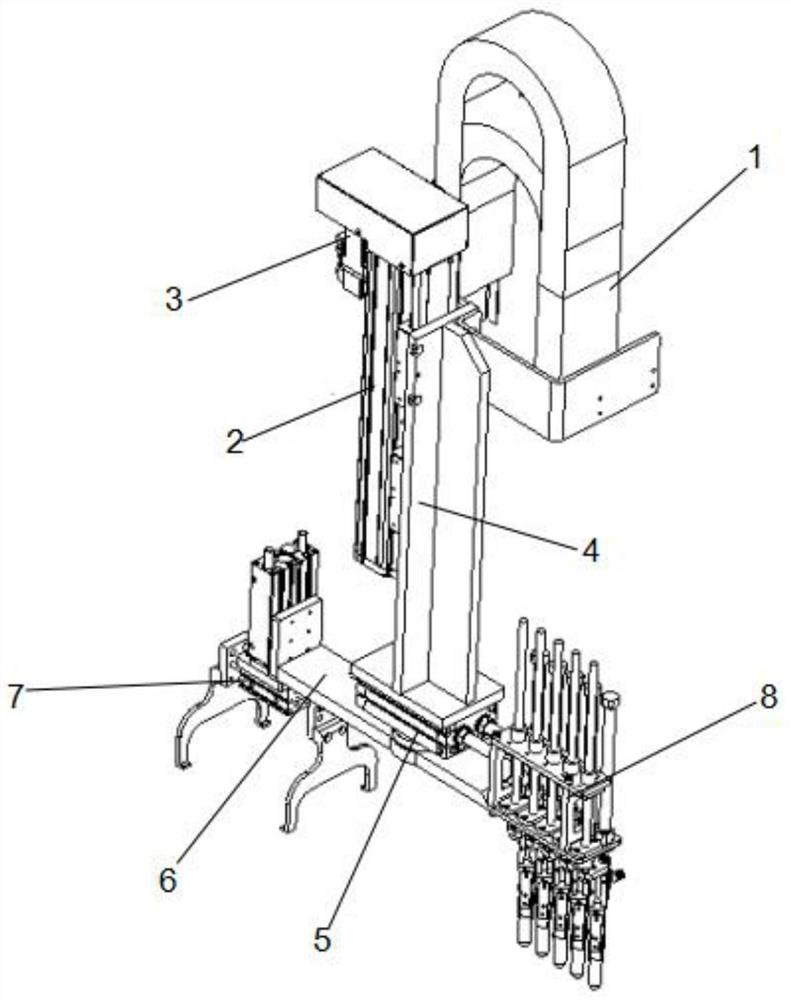

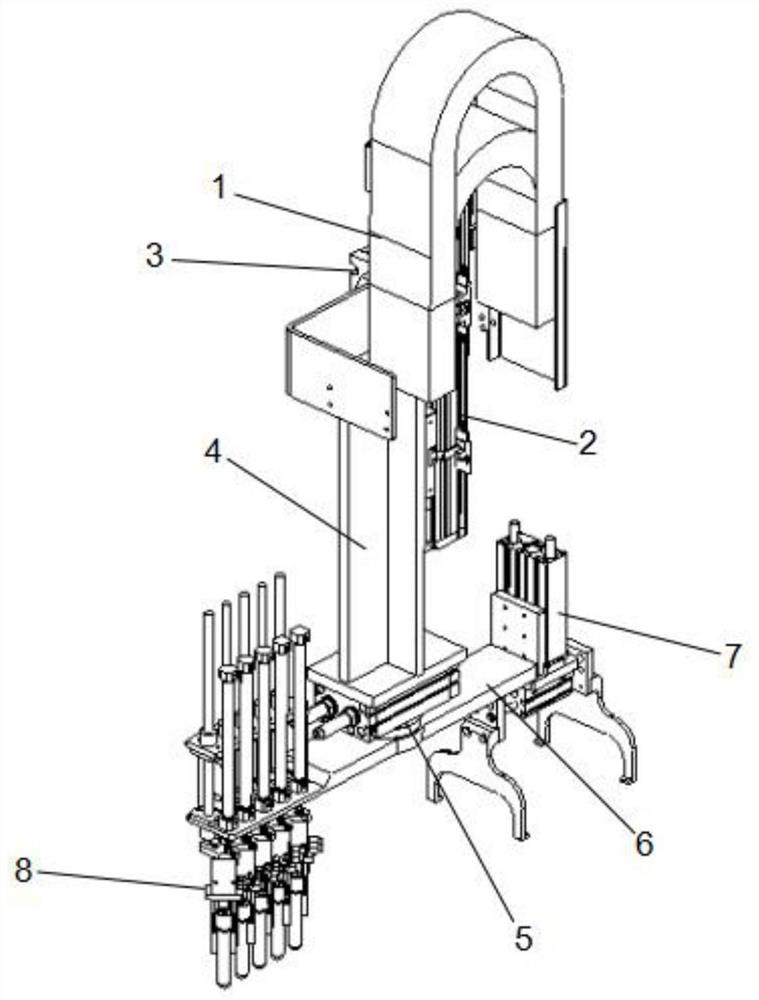

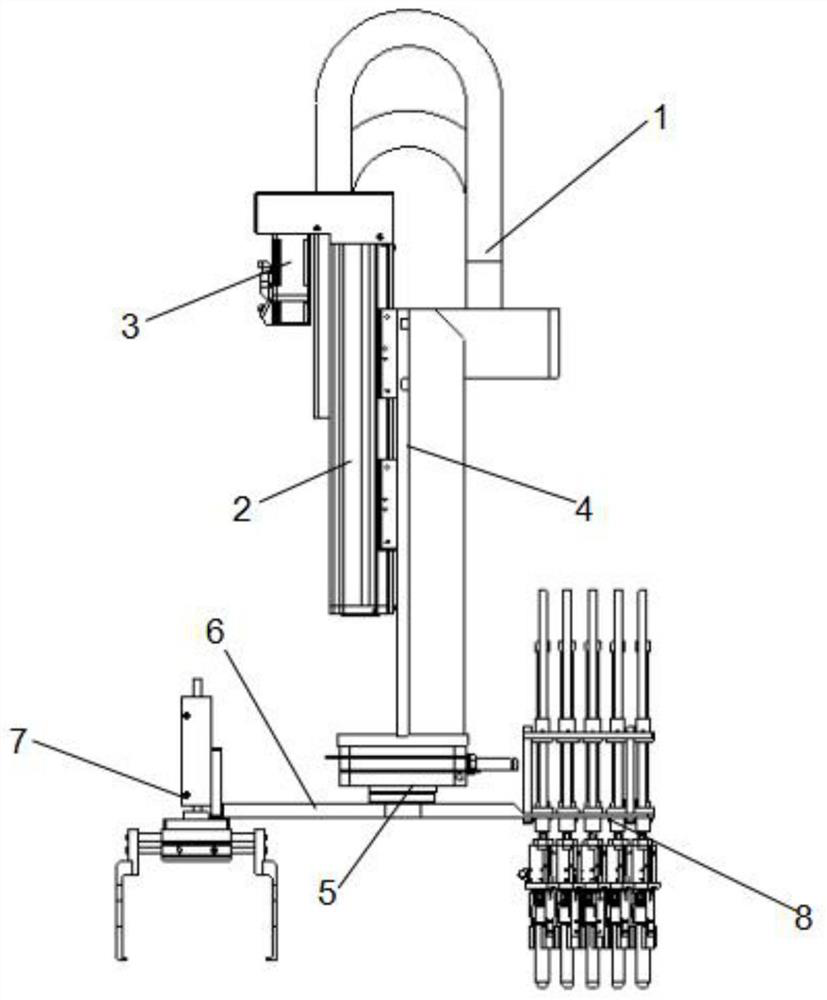

[0018] Embodiment: an automatic sorting module of a test tube sorting machine.

[0019] refer to Figure 1 to Figure 4 As shown, an automatic sorting module of a test tube sorter, including:

[0020] A bracket 1, the bracket 1 is used for docking with an external mobile mechanism;

[0021] The linear slide rail 2 installed on the bracket 1 longitudinally, the drive motor 3 is installed on the linear slide rail 2, the linear slide block 4 is installed on the linear slide rail 2 and drives the linear slide block 4 to slide along the straight line through the drive motor 3 Rail 2 moves up and down to achieve a wide range of up and down movement;

[0022] The rotary cylinder 5 fixed on the bottom of the linear slider 4, the rotary frame 6 is installed on the output shaft of the rotary cylinder 5, and the rotary cylinder 5 can drive the rotary frame 6 to rotate 360° in the horizontal direction;

[0023] The test tube box gripper mechanism 7 installed on one side of the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com