Warpage control structure for metal base plate, semiconductor module, and inverter device

A metal base and metal plate technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

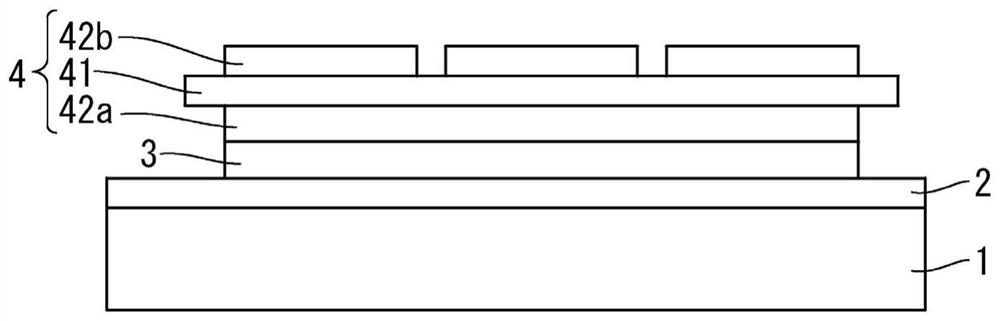

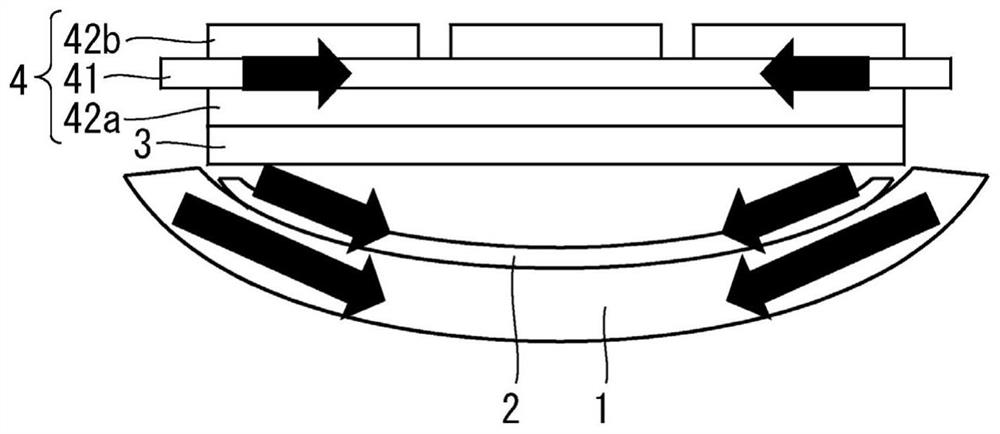

[0026] Embodiments of the present invention will be described below using the drawings. figure 1 It is a side view of the warpage control structure of the metal base plate which concerns on embodiment.

[0027] like figure 1 As shown, the warpage control structure of the metal base plate constitutes a part of the semiconductor module, and the warpage control structure of the metal base plate has a metal base plate 1 , a dissimilar metal layer 2 and an insulating substrate 4 .

[0028] The metal base plate 1 is approximately 100mm×100mm square in plan view, and has a thickness greater than or equal to 3.5mmt and less than or equal to 4.0mmt. In addition, as the material of the metal base plate 1, a material with high thermal conductivity such as aluminum, aluminum alloy, or copper is preferable. In this embodiment, aluminum is selected in order to reduce the total weight.

[0029] The dissimilar metal layer 2 is formed on the entire surface of the metal base plate 1 or only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com