Dynamic detection-based marking device for sponge city engineering

A dynamic detection, sponge city technology, applied to the device for coating liquid on the surface, cleaning method using tools, mechanical thickness measurement, etc., can solve the problems of plate compaction, waste of time, and inability to automatically clean the dust on the plate. , to achieve the effect of preventing markup confusion and avoiding confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Example: Please refer to Figure 1 to Figure 9 :

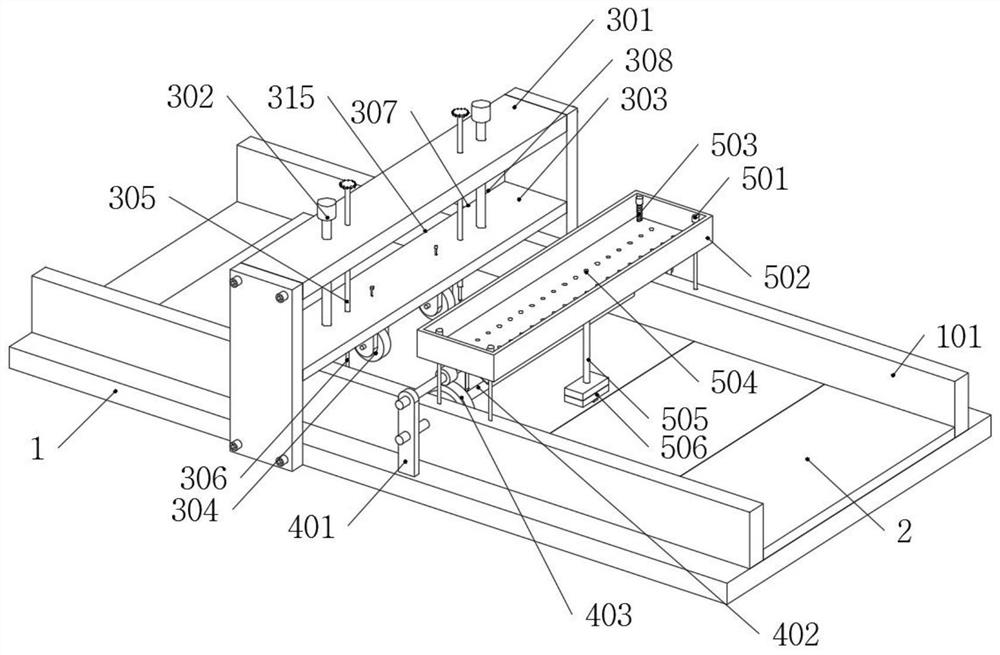

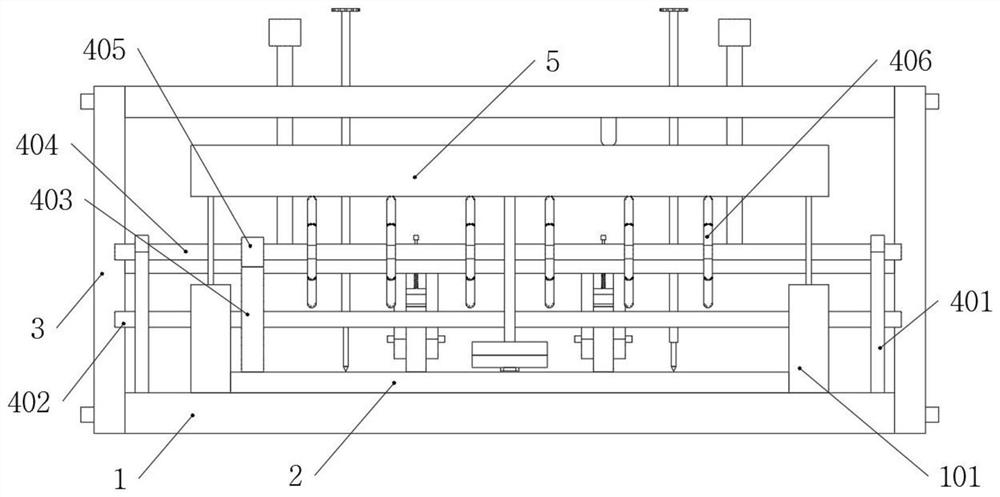

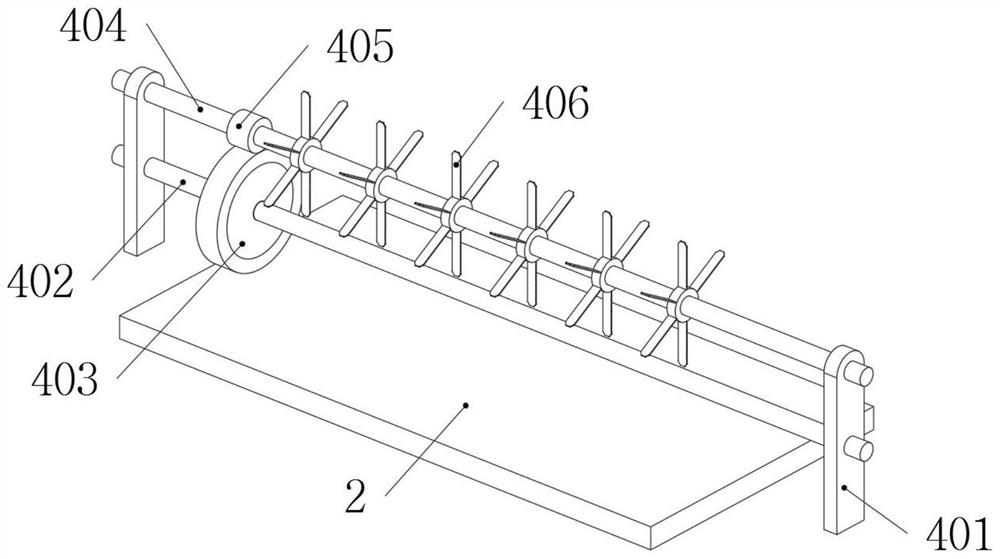

[0046] The present invention proposes a dynamic detection-based marking device for sponge city engineering, including: a main body seat 1, a first marking part 3, a cleaning part 4 and a second marking part 5;

[0047] The main body seat 1 is installed on the workbench through bolts, and two baffle plates 101 are symmetrically welded on the main body seat 1; the plate material 2 is placed in a linear array on the main body seat 1, and the left end surface and the right end surface of the plate material 2 are respectively connected with the two block baffle 101 contact;

[0048] The first marking part 3 is composed of a frame body 301, a sliding rod A302, a mounting seat 303, a roller 304, a threaded rod A305, a marking pen A306, a threaded rod B307, a marking pen B308, a sliding rod B309, a cleaning block 310 and an elastic member B311. And the frame body 301 is fixedly connected to the main body seat 1 by bolts;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com