Double-bearing cross beam bearing pedestal of oil pumping unit

A technology of bearing seat and double bearing, which is applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of reducing the service life of bearings, affecting the normal use of bearings, and inconvenient cleaning of debris, etc., to achieve extended use Long life, prolong the service life of the equipment, the effect of stable and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

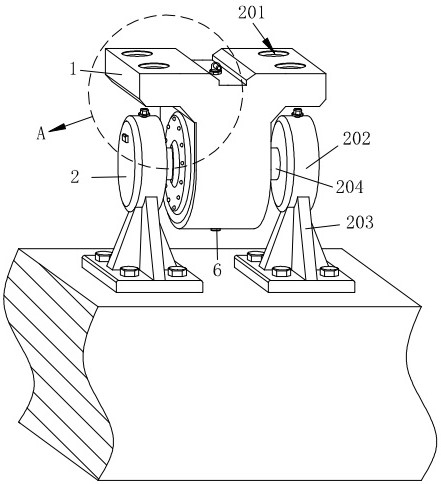

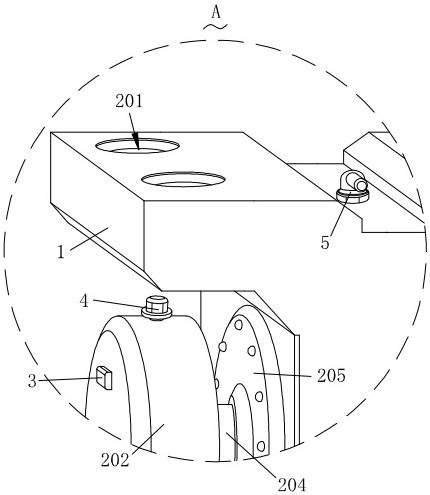

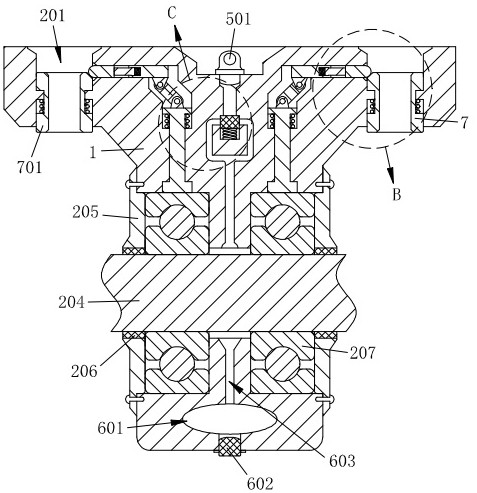

[0031] like Figure 1 - Figure 7 As shown, the biaxial beam beam housing of the bearing machine according to the present invention includes a housing body 1, and a connecting mechanism 2 is mounted on the bearing housing body 1, and the connecting mechanism 2 is mounted. The connecting mechanism 2 is provided with an inuting mechanism 4, and a protective mechanism 3 is attached to the connecting mechanism 2, and a lubricating mechanism 5 is mounted on the connecting mechanism 2, and a collection mechanism 6 is attached.

[0032]Specifically, the fastening mechanism 7 includes a fixing sleeve 701, and four fixing sleeves 701 are provided inside the bearing body 1, the fixing sleeve 701 slides to the bearing seat body 1 by a telescopic spring 702, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com