Warp drawing equipment for canvas production

A kind of equipment and canvas technology, applied in the field of warp pulling equipment, can solve problems such as affecting the quality of textile products, yarn wear, and affecting the respiratory health of staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

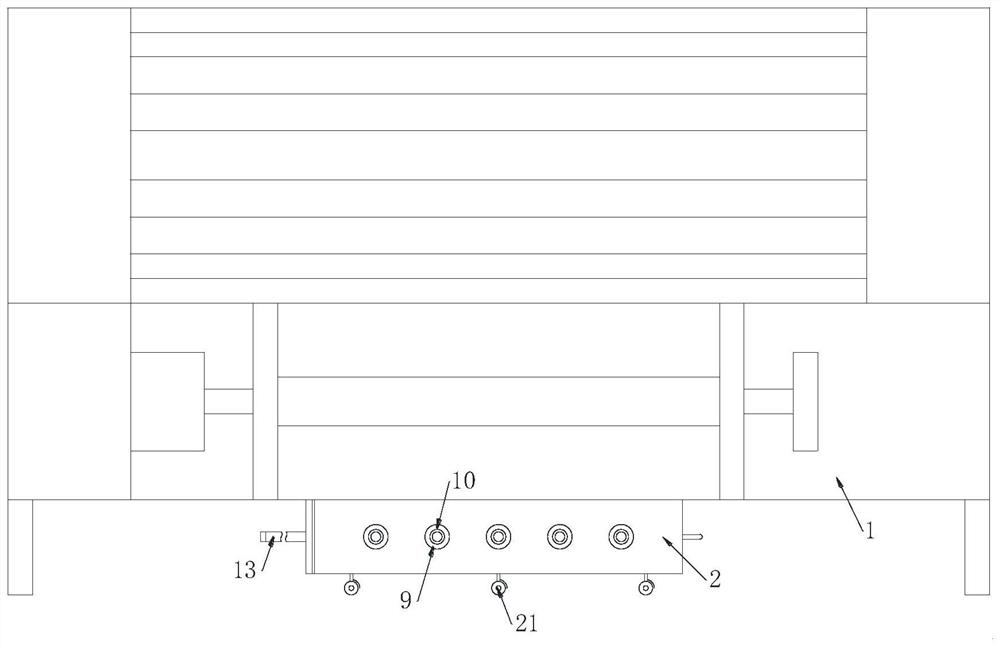

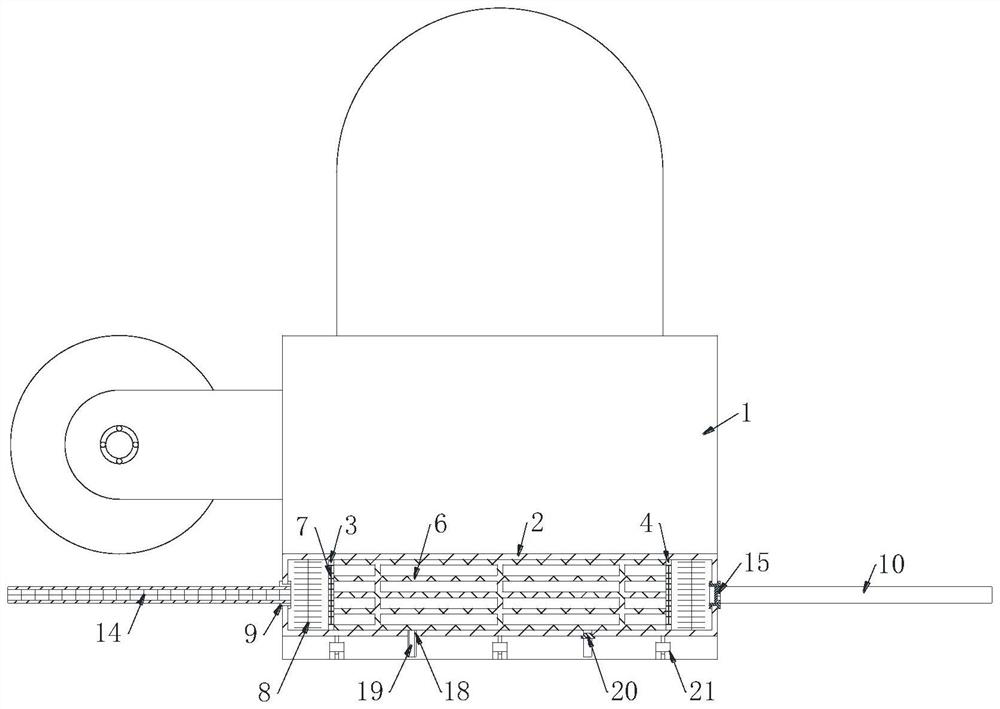

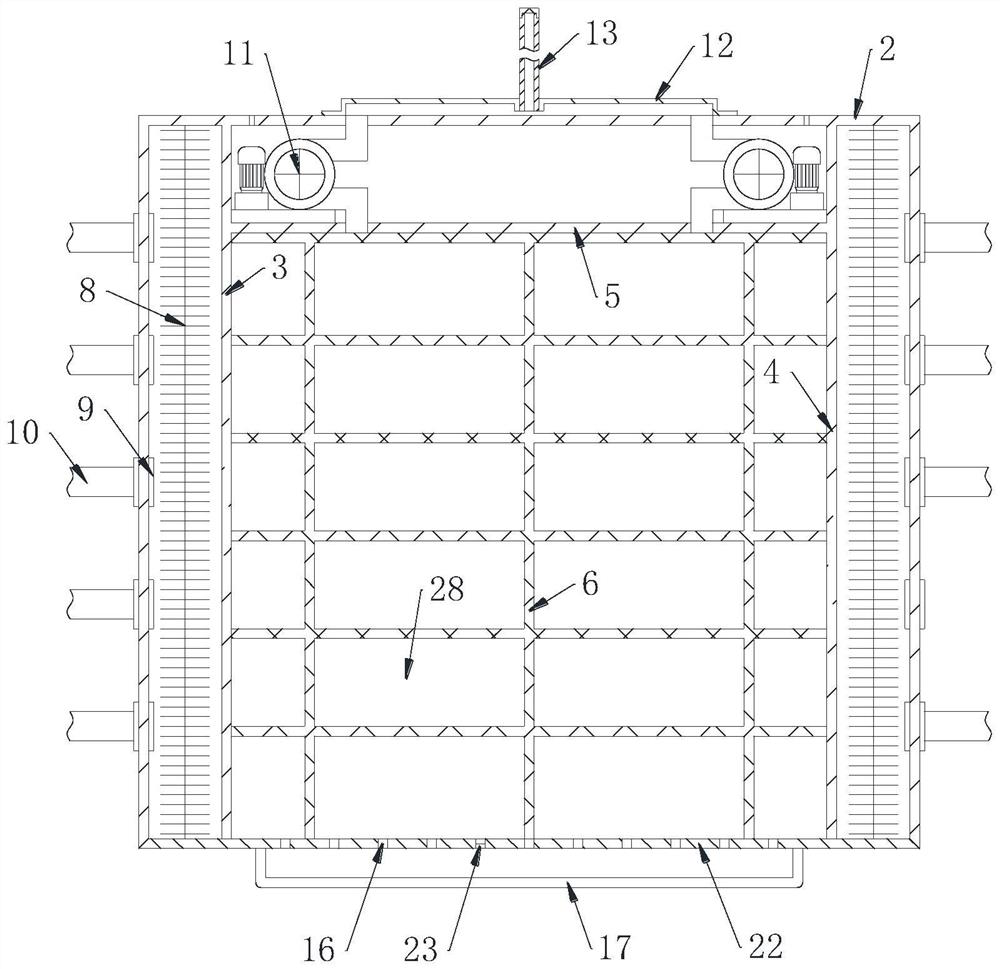

[0026] see Figure 1-4 As shown, a warp-drawing device for canvas production includes a warp-drawing machine 1, a dust removal box 2, a left partition 3, a right partition 4 and a dust removal unit; the lower end of the warp-drawing machine 1 is plugged with Dust removal box 2; one side of the dust removal box 2 is grooved and detachably fixed with a quick release plate 22; the interior of the dust removal box 2 is symmetrically sealed and fixed with a left partition plate 3 and a right partition plate 4 ; Between the left partition plate 3 and the right partition plate 4, the middle partition plate 5 is sealed and fixed; the inside of the dust removal box 2 is provided with a dust removal unit; the dust removal unit includes a filter screen 7, a first Metal mesh 8, threaded interface 9 and first gooseneck 10; All grooves in the left partition plate 3 and the right partition plate 4 are fixed with filter screens 7; The left partition plate 3 and the right partition A first me...

Embodiment 2

[0035] see Figure 5 As shown in Comparative Example 1, as another embodiment of the present invention, the first gooseneck 10 is sleeved with a sleeve 24; the sleeve 24 is fixed with a fixing plate 25; the fixing An elastic member 26 is fixedly connected to the plate 25; the other end of the elastic member 26 is fixedly connected with a clamping plate 27; the clamping plate 27 is slidably sleeved on the sleeve 24; Make the spacing between the clamping plate 27 and the fixed plate 25 increase, so that it can be clamped on other objects, and the clamping plate 27 and the fixed plate 25 are kept clamped by the elastic member 26, so that the first gooseneck 10 Can be fixed to or fixed to other objects.

[0036] The working principle is that the negative pressure machine 11 is connected to the mains to work, and then the air negative pressure is generated, and the fiber filter block 6, the filter screen 7, the threaded interface 9 and the first gooseneck 10 are in contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com