Device for fixing knitting parts on needle bar pad of warp knitting machine and auxiliary tool

A technology of knitting parts and fixing devices, which can be used in warp knitting, knitting, textiles and papermaking, etc., and can solve problems such as difficult replacement of skateboards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

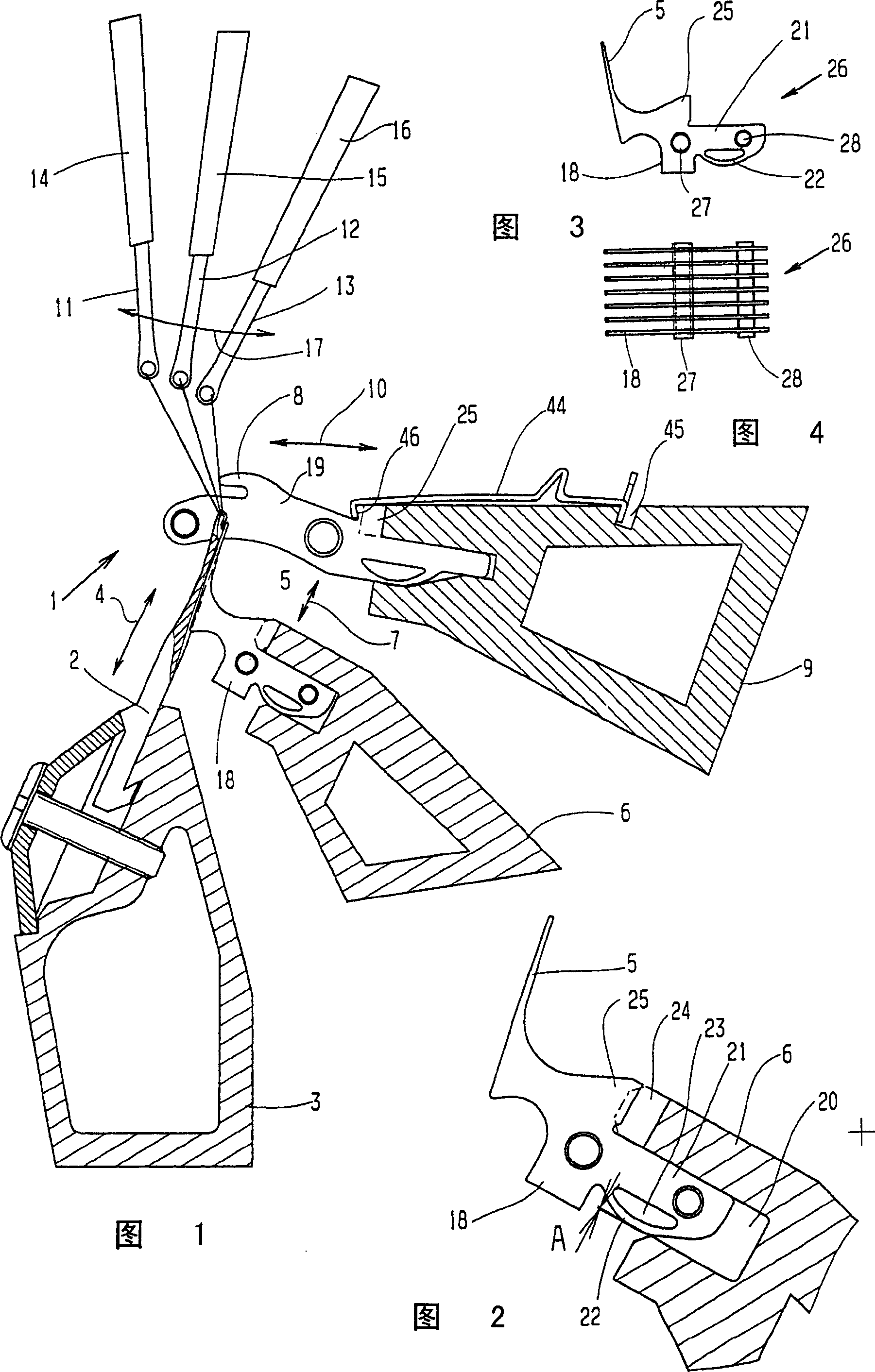

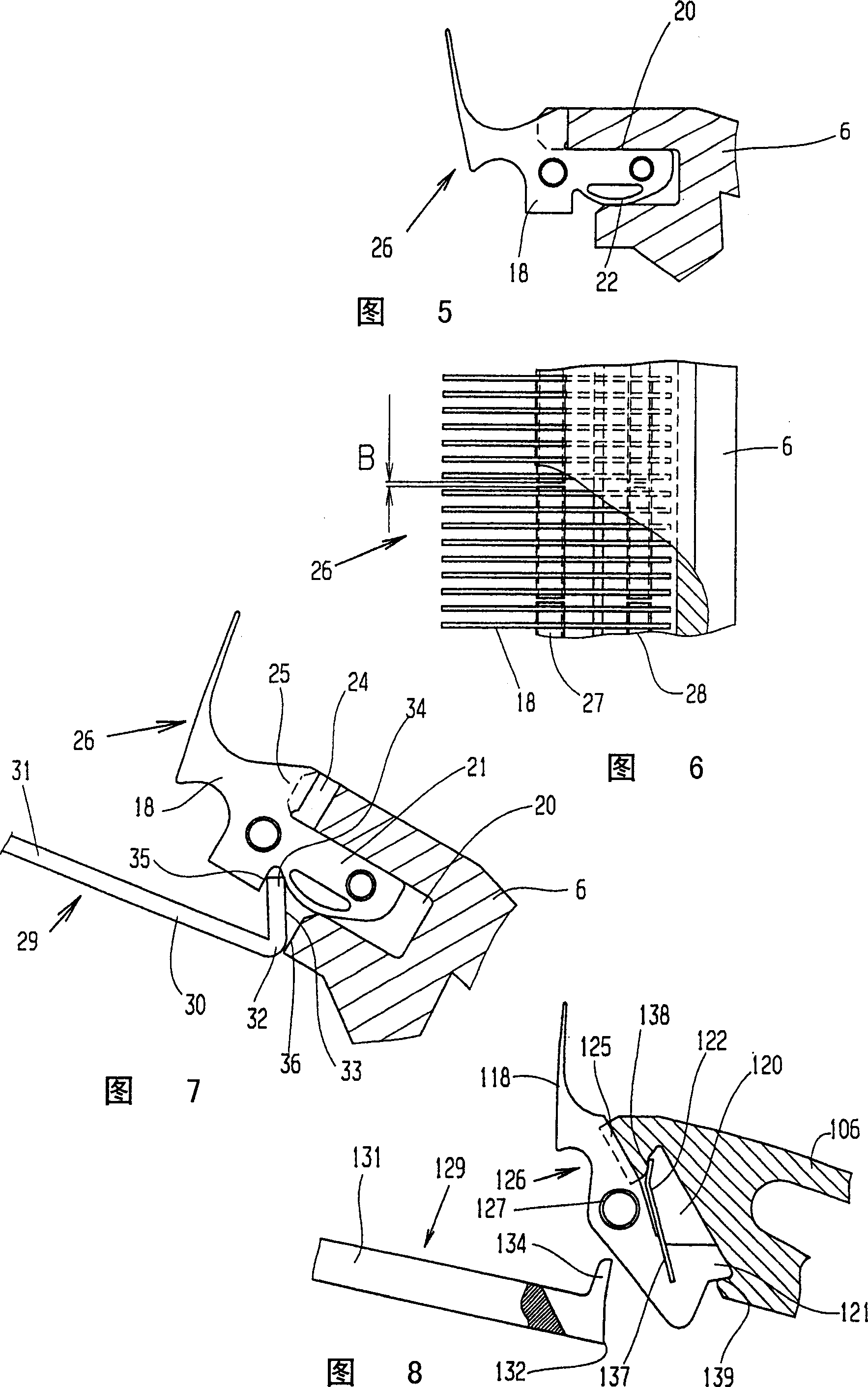

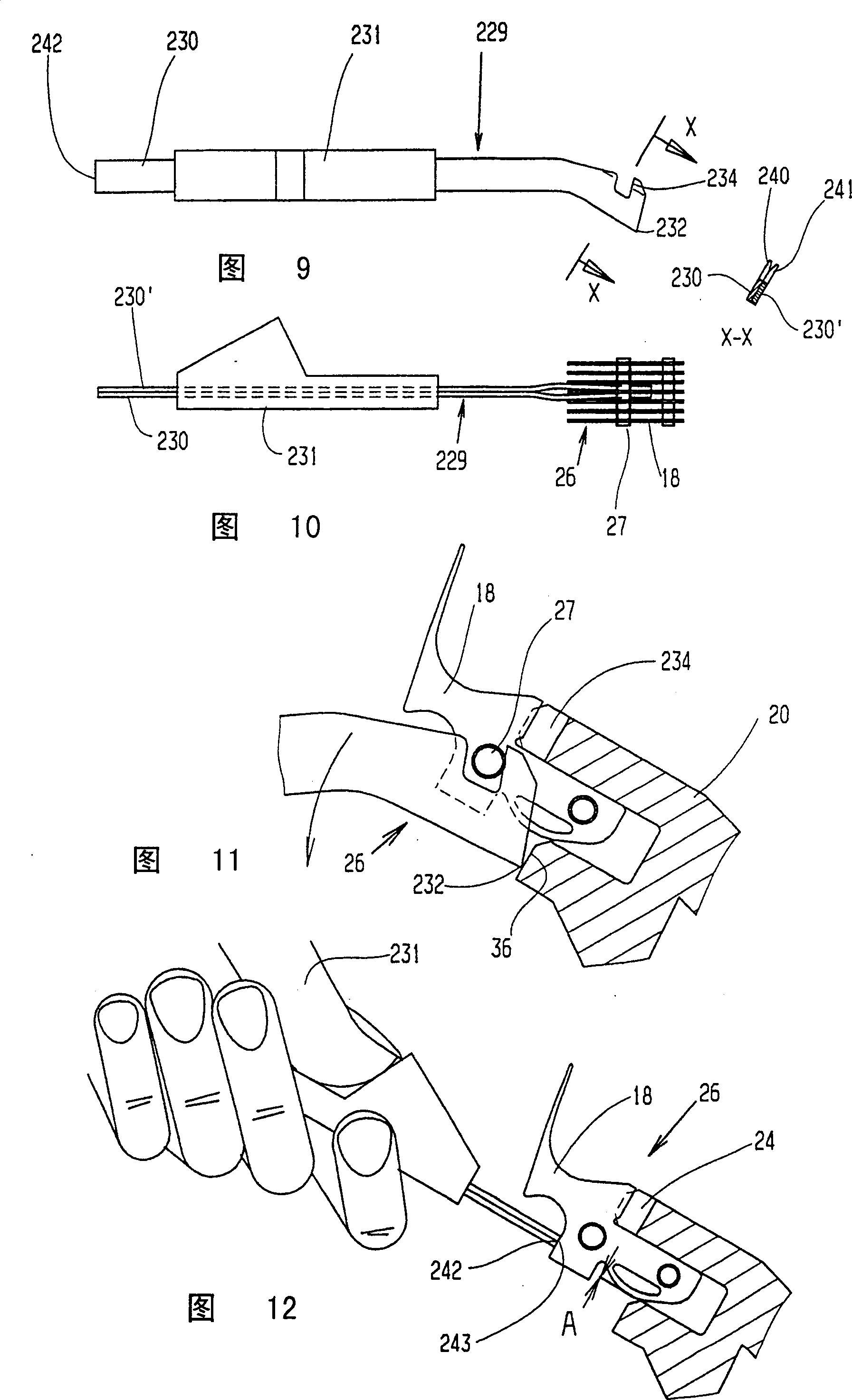

[0035] Figure 1 shows the working area 1 of the warp knitting machine. In the working area, multiple knitted components work together, that is, the crochet needle 2 on the crochet beam 3 moves back and forth in the direction of the arrow 4, and the slide plate 5 on the slide bar 6 is in Move back and forth in the direction of arrow 7, the gripping and knock-off sinker 8 located on the sinker seat 9 reciprocates in the horizontal direction of arrow 10, and the guide pins 11, 12 and 13 on the bars 14, 15 and 16 are in It moves back and forth in the direction of arrow 17 and moves perpendicular to the plane of the drawing. The crochet needle 2 and the guide needles 11, 12 and 13 are fixed to the needle mattress in the usual way. The knitted component 18 constituting the skateboard and the knitted component 19 constituting the gripping knock-off sinker correspond to the present invention.

[0036] Hereinafter, the present invention will be described in connection with knitted componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com