Method and equipment for evaluating dispersion degree of white carbon black in rubber material and computer readable carrier medium

A technology of dispersion degree and silica, applied in the direction of analyzing materials, material inspection products, flow characteristics, etc., can solve problems such as affecting the final performance of rubber compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

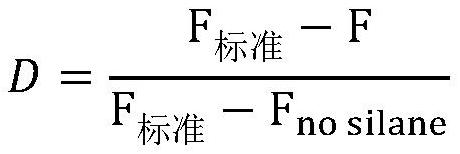

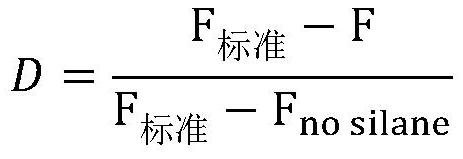

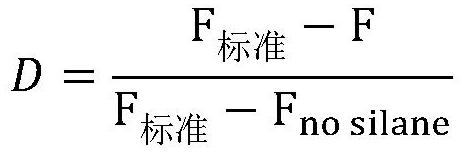

[0037] EXAMPLES By using different silane coupling agents and different processes to improve the dispersion of silica formulations, and then using a rubber flow analyzer to measure the flow value of each scheme, the dispersion of silica is calculated.

[0038] Test formulas A-D, standard formulas, and silane-free coupling agent formulas are shown in Table 1:

[0039] Table 1 embodiment formula table

[0040] raw material Option A Option B Plan C Plan D Standard formula Silane Free Formula Solution Polystyrene Butadiene Rubber 70.0 70.0 70.0 70.0 70.0 70.0 Butadiene rubber 30.0 30.0 30.0 30.0 30.0 30.0 Silica 80.0 80.0 80.0 80.0 80.0 80.0 Silane coupling agent Si69 7.0 7.0 7.0 Silane coupling agent Si747 12.98 Silane coupling agent Si137 7.33 softening oil 31.25 31.25 31.25 31.25 31.25 31.25 other 10.1 10.1 10.1 11.24 11.67 10.1 total number of copies 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com