Folding type large formwork top pouring platform bearing support

A large formwork, foldable technology, applied in construction, building structure, scaffolding accessories, etc., can solve the problems of inconvenient construction and on-site safety management, large formwork cannot be stacked, and consumes a lot of manpower and material resources. The degree of assembly and product quality control, saving storage and transportation space, optimizing the effect of transportation and storage management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the invention and implement it, but the examples given are not intended to limit the invention.

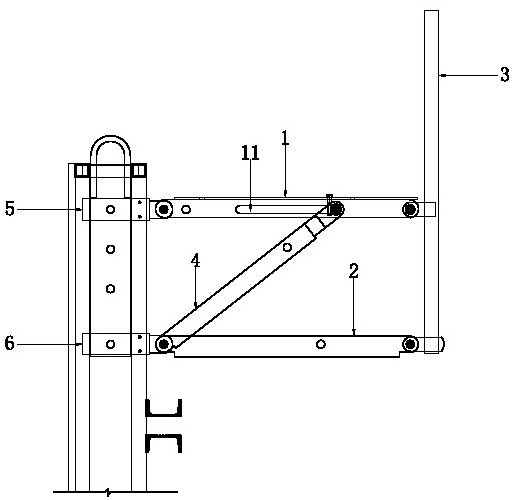

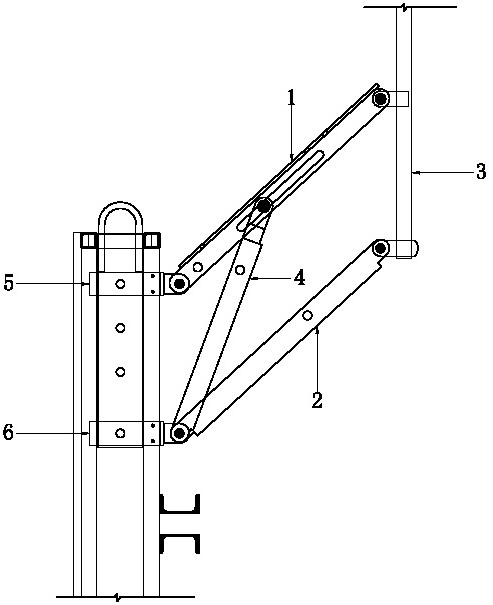

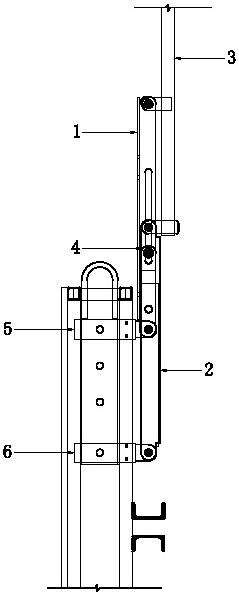

[0025] Such as figure 1 As shown, the present invention is a foldable large formwork top pouring platform load-bearing support, including a first cross bar 1, a second cross bar 2, a vertical bar 3, a pressure-bearing inclined bar 4, an upper connecting support 5, a lower The connecting support 6, the first horizontal bar 1 and the second horizontal bar 2, the vertical bar 3, the pressure-bearing oblique bar 4, the upper connecting support 5 and the lower connecting support 6 are movably connected with each other to form a foldable large formwork top pouring platform Bearing bracket.

[0026] The second cross bar 2 is located below the first cross bar 1, the vertical bar 3 is located on the right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com