A connector for lattice type wind power tower

A connector and lattice-type technology, which is applied in the field of connectors for lattice-type wind power towers, can solve problems such as unreasonable force, long time consumption, and difficult construction, so as to avoid residual stress and residual deformation, and ensure on-site installation Convenience, effect of guaranteed detachability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

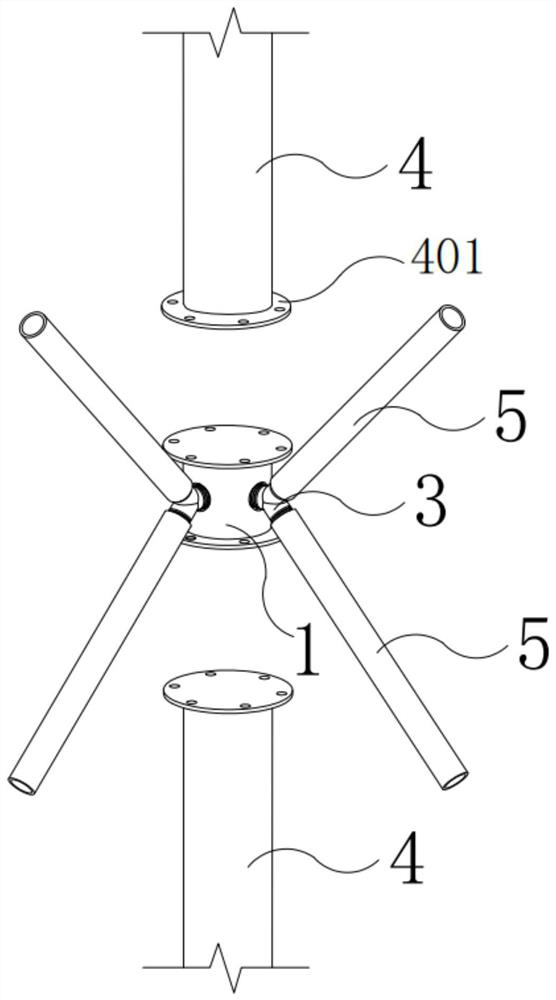

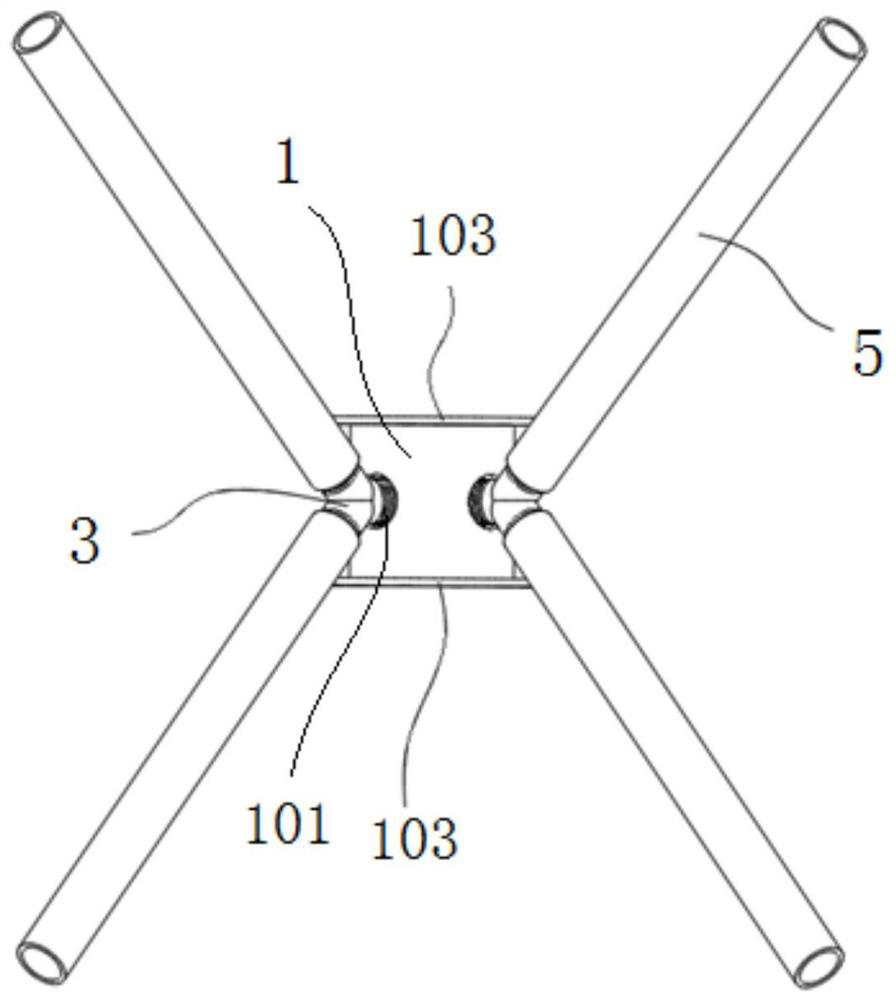

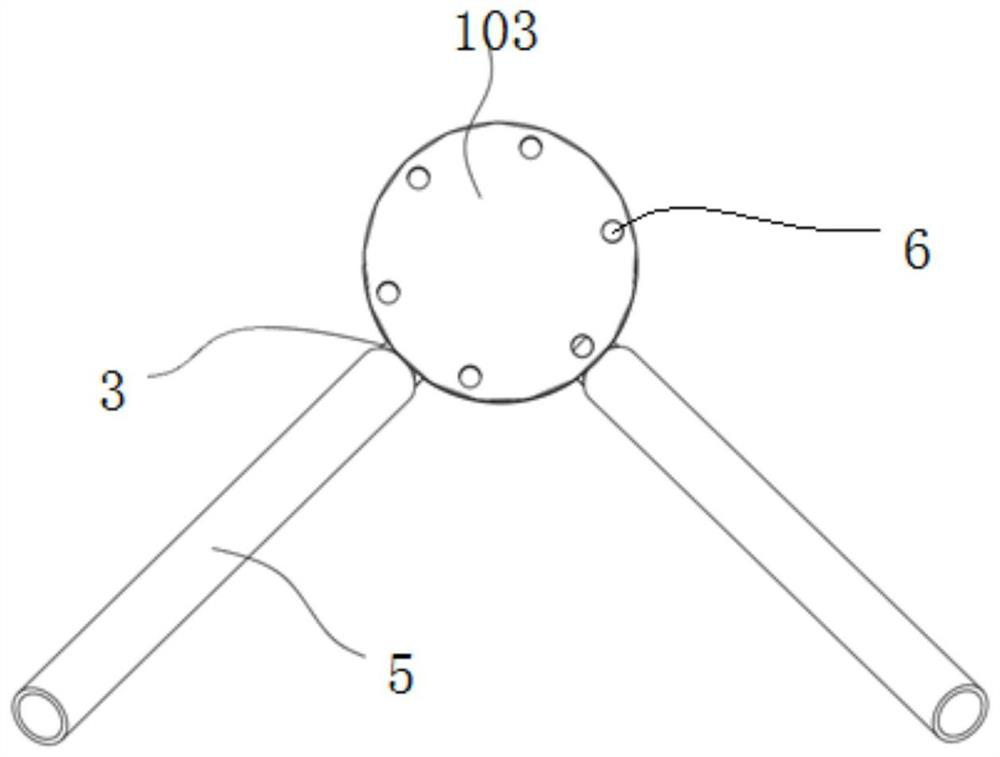

[0036] The specific implementation is as follows: in the factory prefabrication, the Y-shaped connector 3 is screwed into the threaded hole of the bolt ball 2 embedded in the steel pipe 102, and in the field installation, the steel pipe 102 is threaded through high-strength bolts according to the pre-designed node positions. Connect and fix with the lower tower column 4, and ensure that it is firmly connected to the tower column 4. One end of the web rod 5 is connected to the end of the Y-shaped connector 3 support rod 302, and the steel pipe 102 is connected to the upper tower column 4 through high-strength bolts through high-strength bolts. Fixed and connected in sequence in this way to form a complete lattice-type concrete-filled steel tubular wind power tower. The whole construction process does not require on-site welding, but only needs to be connected by bolts, which is convenient for on-site installation, avoiding the residual stress and residual deformation caused by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com