Automobile charging port cover mold

A car charging and charging port technology, which is applied in the field of auto parts manufacturing, can solve the problems of complex product parts, increased assembly process and cost, and heavy product assembly, so as to reduce development costs, reduce parts parts, and avoid stuck hysteresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Example embodiments will now be described more fully with reference to the accompanying drawings. Example embodiments may, however, be embodied in many forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the concept of example embodiments to those skilled in the art. The same reference numerals in the drawings denote the same or similar structures, and thus their detailed descriptions will be omitted.

[0031] The terms "a", "an", "the", "said" are used to indicate the presence of one or more elements / components / etc; the terms "comprising" and "have" are used to indicate an open-ended inclusion means and means that additional elements / components / etc. may be present in addition to the listed elements / components / etc.

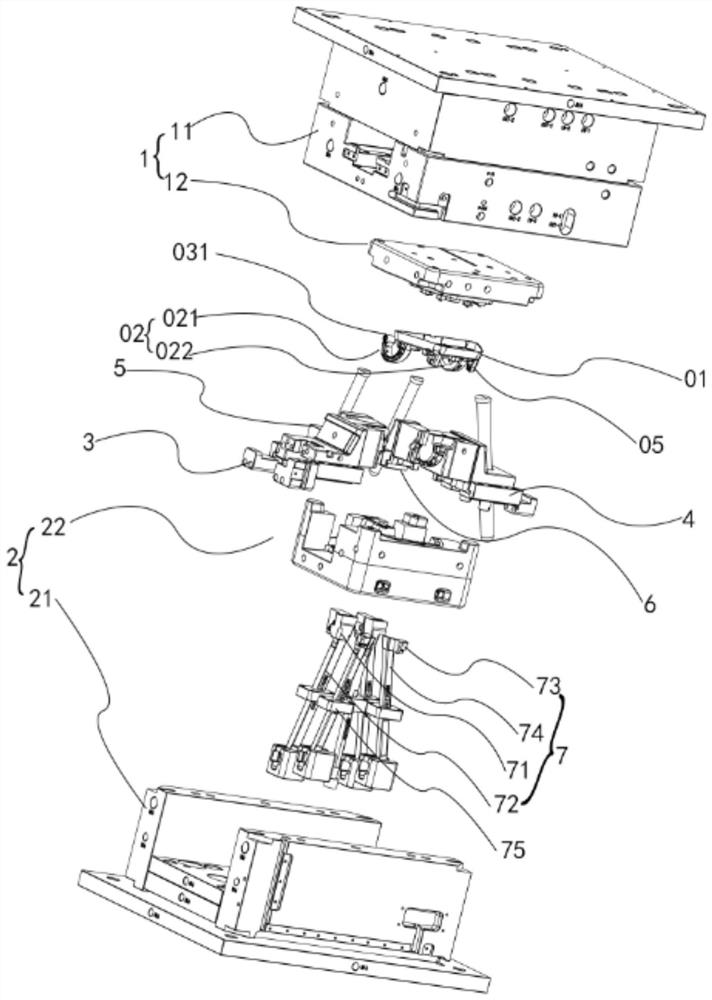

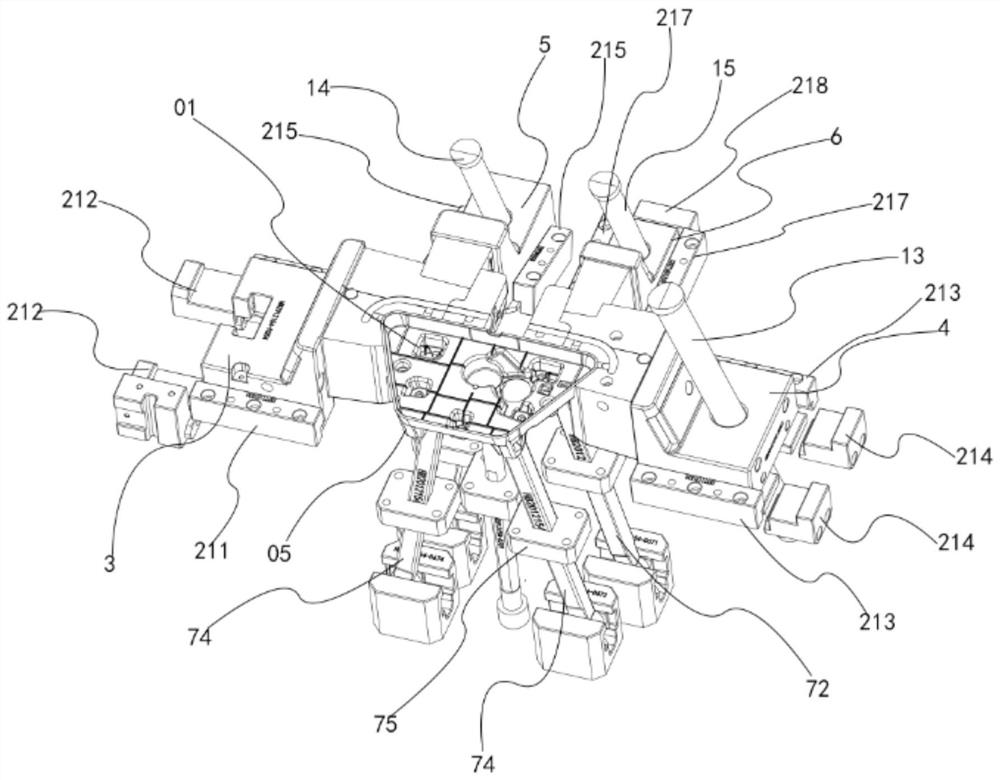

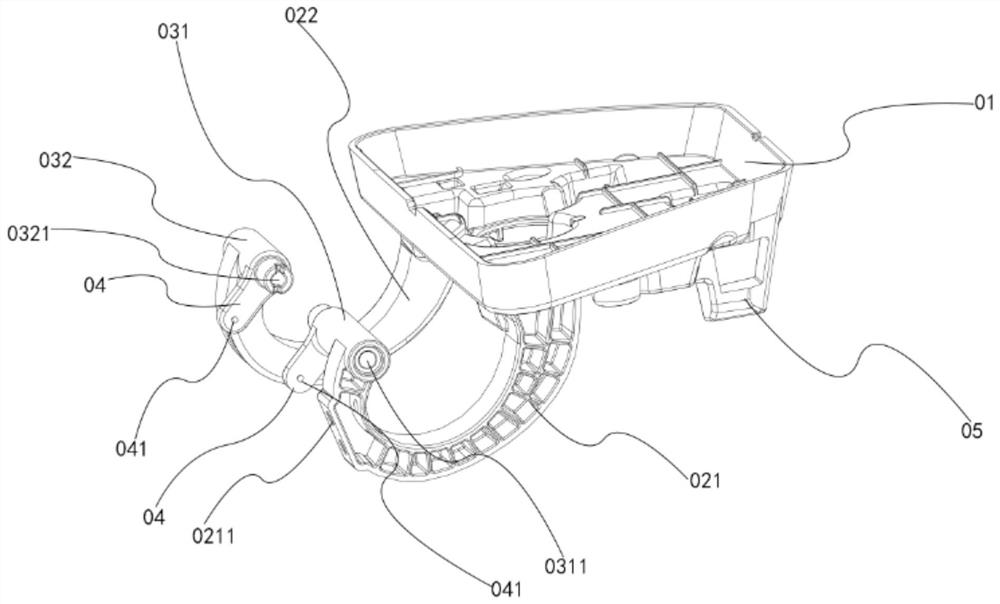

[0032] Such as Figure 1 to Figure 10 as shown, figure 1 An exploded view of an automobile charging port co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com